Cogging method for reducing surface decarburization depth of medium-high carbon steel blank

A deep decarburization, medium-high carbon technology, applied in the field of iron and steel metallurgy manufacturing, to achieve the effect of reducing the thickness, reducing the time of high temperature, and reducing the amount of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

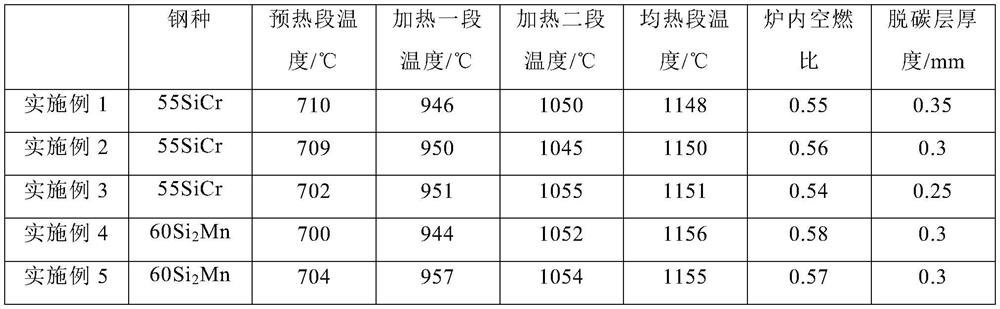

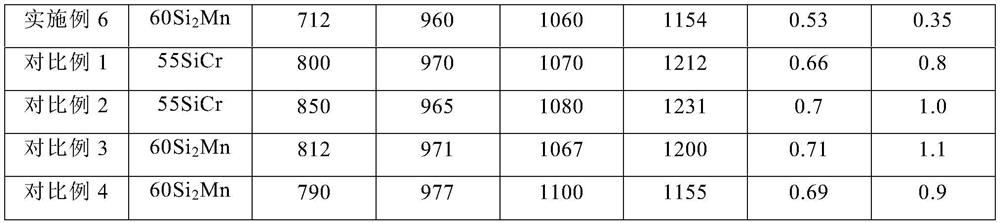

Embodiment 1

[0042] The bloom used in Embodiment 1 of the present invention is a 55SiCr steel grade with a section size of 300mm*390mm. The design capacity of the heating furnace is 154 pieces. The heating time required for the bloom to be heated to the rolling condition is 190min. The billet time is 95s, and the number of billets in the heating furnace is calculated to be 120. Perform the following operations on the 55SiCr bloom with a section size of 300mm*390mm:

[0043] S1 billet heating: put the above-mentioned bloom into the heating furnace through the roller table. The heating furnace is divided into four sections, namely the preheating section, the heating section 1, the heating section 2 and the soaking section. The temperature of the preheating section is 710°C. The temperature of the first stage of heating is 946°C, the temperature of the second stage of heating is 1050°C, and the temperature of the soaking stage is 1148°C. Blast furnace gas is used as fuel, and the air-fuel ra...

Embodiment 2

[0047] The bloom used in the second embodiment of the present invention is 55SiCr steel with a section size of 300mm*390mm. The design capacity of the heating furnace is 154. The heating time required for the bloom to be heated to the rolling condition is 190min. The billet time is 95s, and the number of billets in the heating furnace is calculated to be 120. Perform the following operations on the 55SiCr bloom with a section size of 300mm*390mm:

[0048] S1 billet heating: put the above-mentioned bloom into the heating furnace through the roller table. The heating furnace is divided into four sections, namely the preheating section, the heating section 1, the heating section 2 and the soaking section. The temperature of the preheating section is 709°C. The temperature of the first stage of heating is 950°C, the temperature of the second stage of heating is 1045°C, and the temperature of the soaking stage is 1150°C. Blast furnace gas is used as fuel, and the air-fuel ratio in...

Embodiment 3

[0052] The bloom used in the third embodiment of the present invention is 55SiCr steel with a cross-sectional size of 300mm*390mm. The design capacity of the heating furnace is 154. The heating time required for the bloom to be heated to the rolling condition is 190min. The billet time is 95s, and the number of billets in the heating furnace is calculated to be 120. Perform the following operations on the 55SiCr bloom with a section size of 300mm*390mm:

[0053] S1 billet heating: put the above-mentioned bloom into the heating furnace through the roller table. The heating furnace is divided into four sections, namely the preheating section, the heating section 1, the heating section 2 and the soaking section. The temperature of the preheating section is 702°C. The temperature of the first stage of heating is 951°C, the temperature of the second stage of heating is 1055°C, and the temperature of the soaking stage is 1151°C. Blast furnace gas is used as fuel, and the air-fuel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com