Liquid food cooking method and cooking device

A cooker and food technology, which is applied in the field of liquid food cooking and liquid food cooker, can solve the problems of high power consumption motor, clogging of filter mechanism by protein components, difficult variety of liquid food, etc., to prevent leakage and maintain airtightness , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

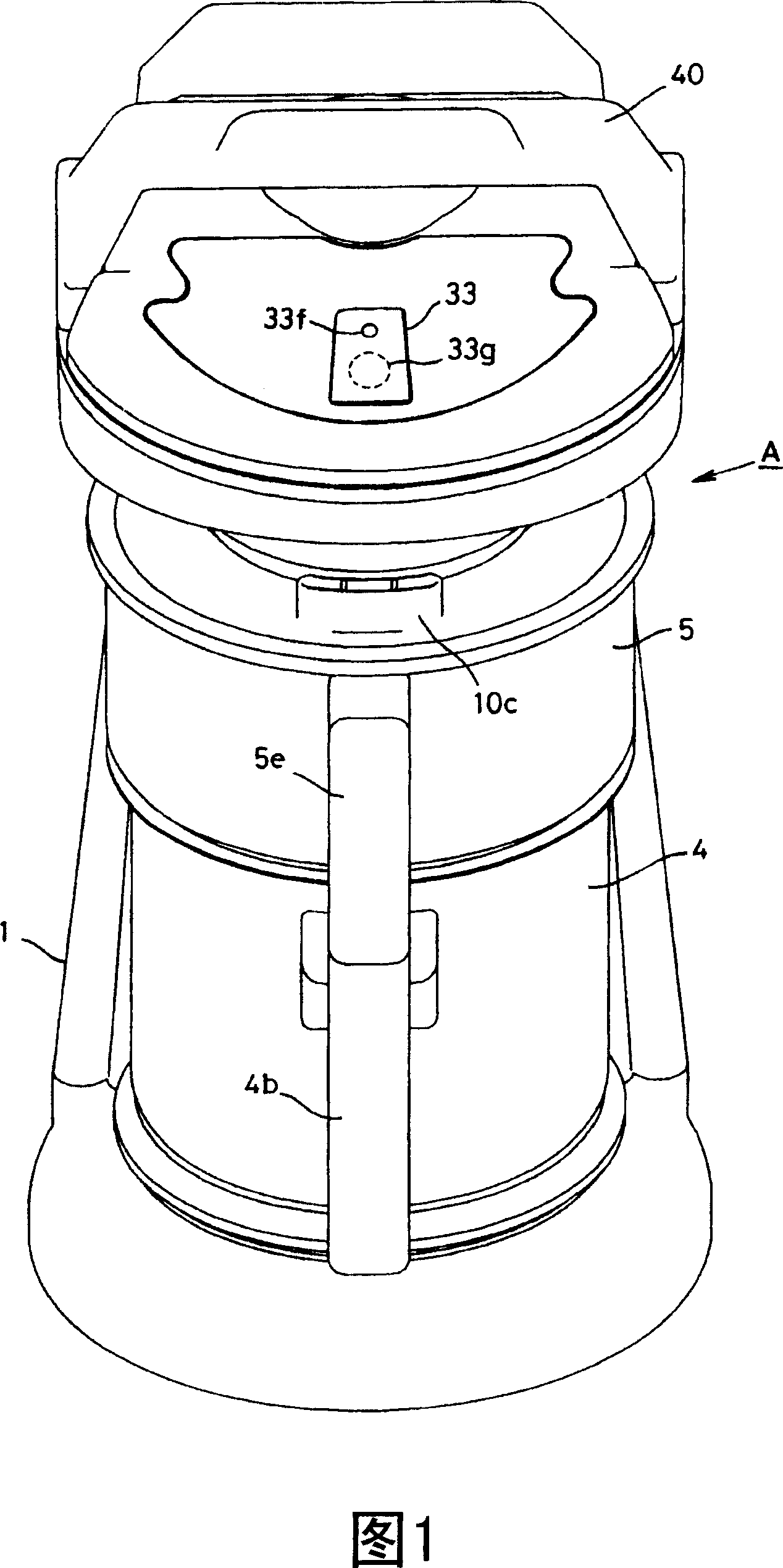

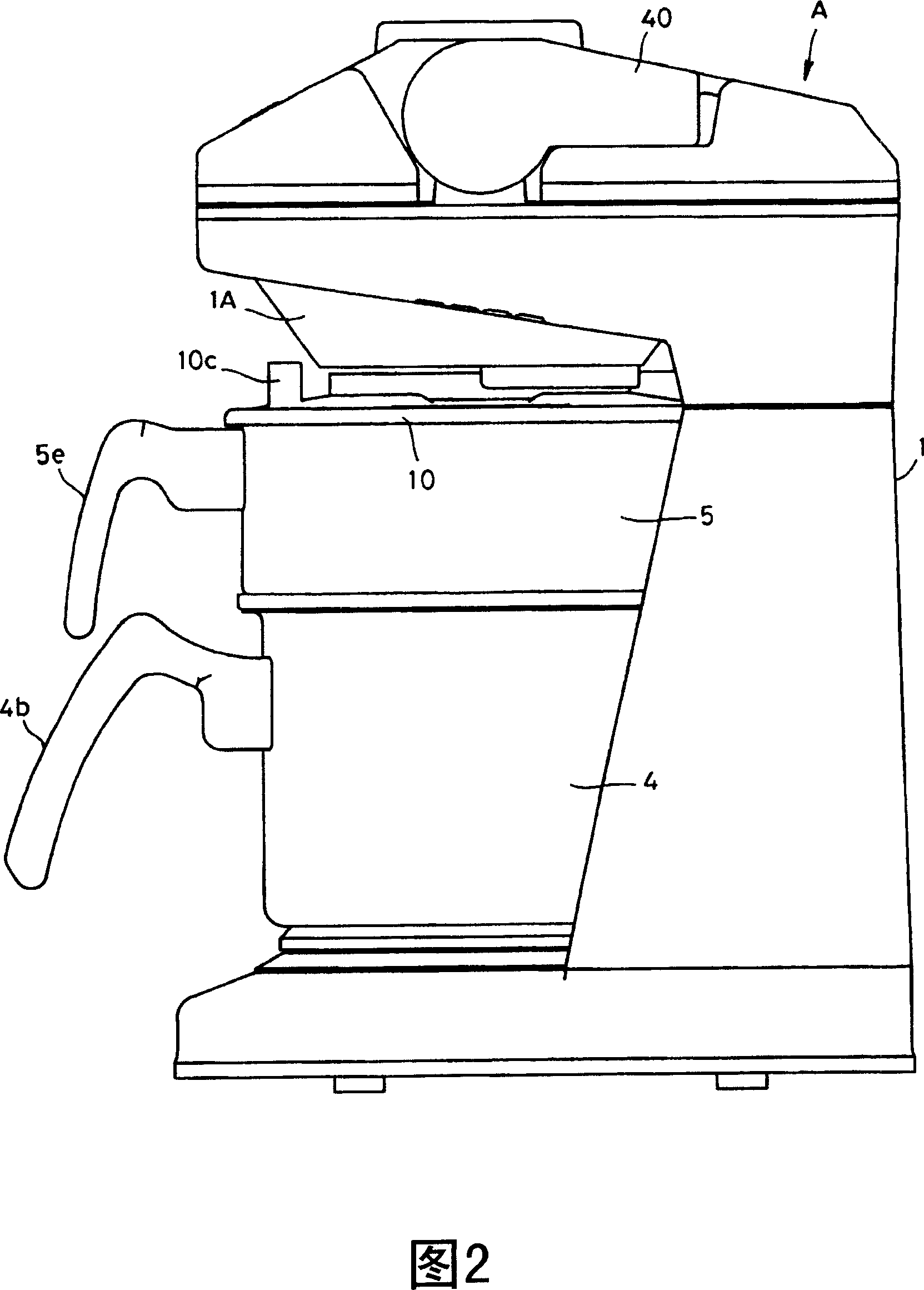

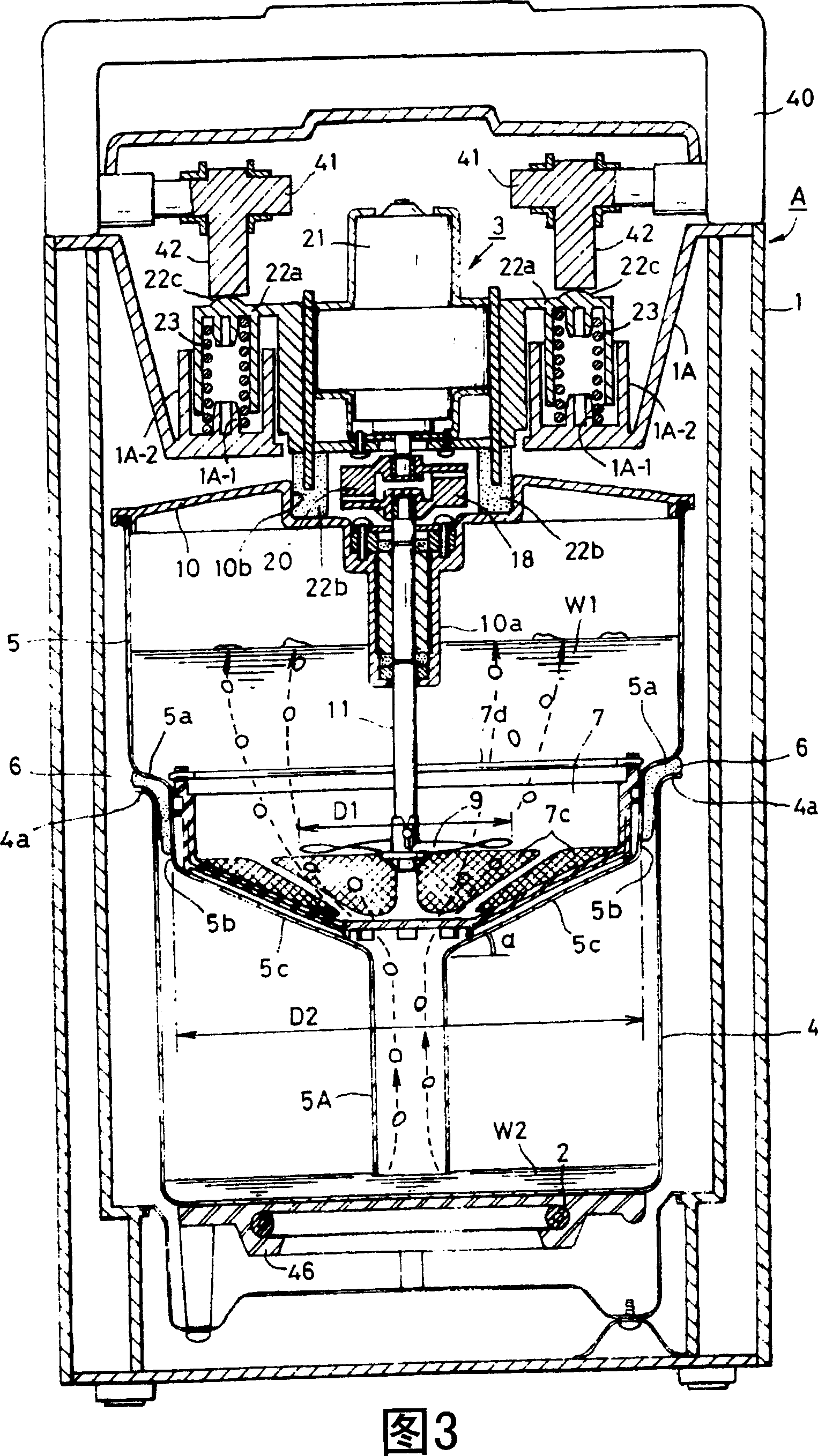

[0099] Fig. 1 is a front perspective view of a liquid food cooker A embodying the present invention, Fig. 2 is a side view thereof, and Fig. 3 is a sectional view. In each figure, the components of the device are largely composed of a main body (base) 1, a pressure vessel (lower vessel) 4, and an extraction vessel (upper vessel) 5 mounted on the pressure vessel 4. The front surface of the main body 1 is Open, the bottom surface is equipped with a heater 2 as a heating mechanism, and a power mechanism 3 is built in the upper part. The above-mentioned heater 2 is generally made of electric heating wire, but it is also possible to use an induction heating coil. At this time, as long as an aluminum layer is laid on the outer bottom surface of the pressure vessel 4, and SUS430 stainless steel is laid on it by appropriate methods such as welding or welding. A magnetic layer made of a magnetic material such as iron or iron is sufficient.

[0100] The pressure vessel 4 is formed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com