Method and device for producing a semiconductor layer

A semiconductor and thin-layer technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, final product manufacturing, etc., can solve problems such as reducing the growth rate of the absorbing layer, improve electrical layer characteristics, reduce material costs, small purchase and maintenance The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the invention is elucidated by means of examples.

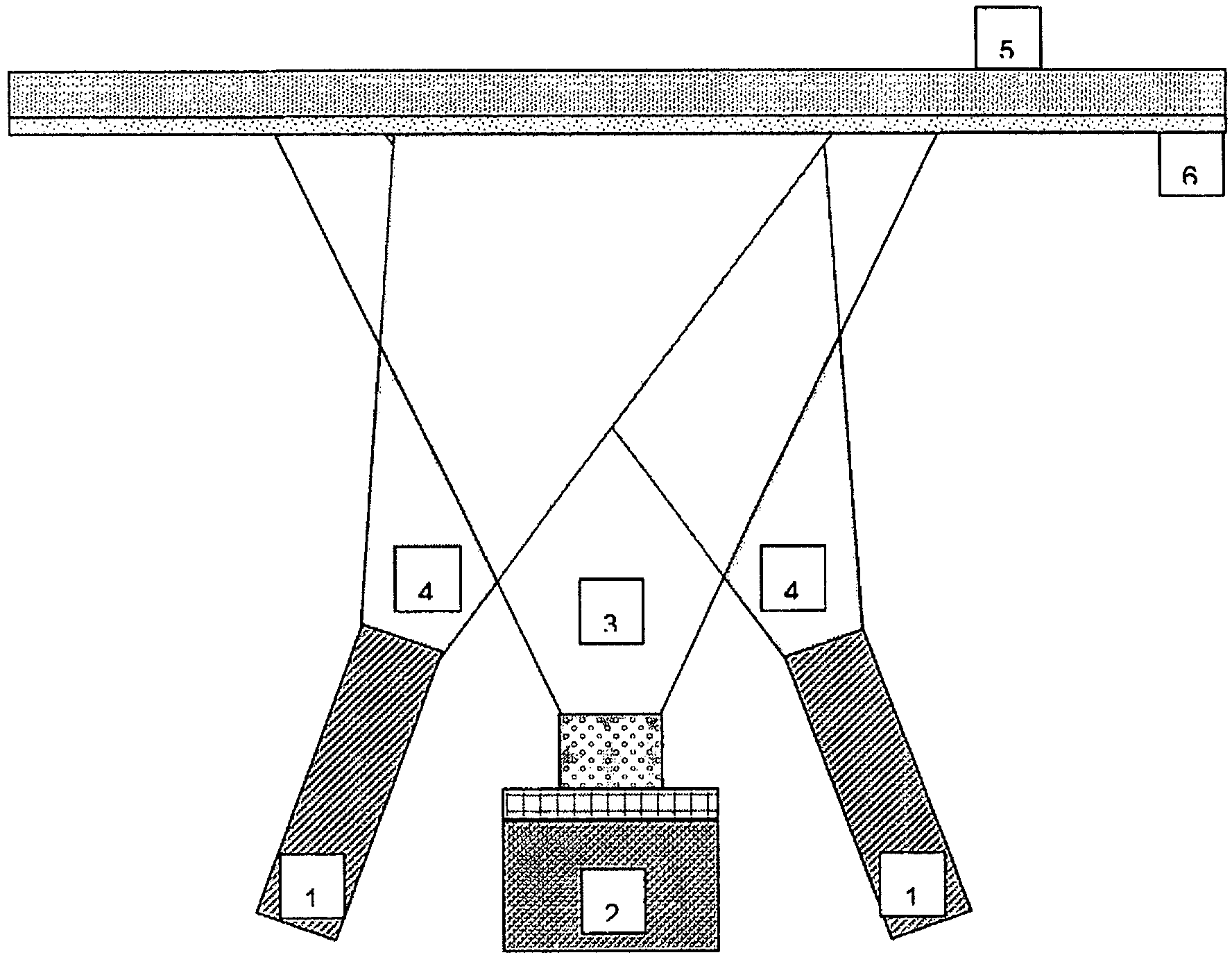

[0037] The substrate 5 provided with the molybdenum-countercontact layer 6 is placed in the coating chamber. In this case, the layer thickness of the molybdenum countercontact layer 6 lies in the range of 0.5 to 2 μm.

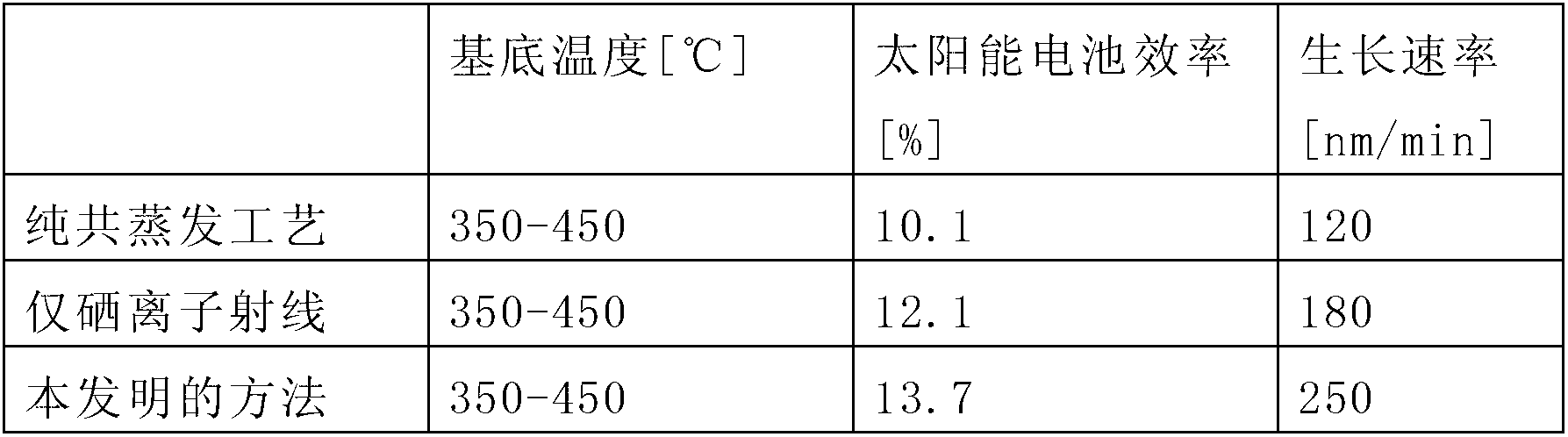

[0038] Now, in a vacuum process with 1×10 -6 and 1×10 -4 The pressure between mbar is coated with Cu(In,Ga)Se on the metal counter contact layer 6 2 semiconductor layer. Here, the metal components from the metal evaporator source 1 evaporate at a ratio of 0.81<Cu / (In+Ga)<0.95. The selenium required for layer formation is provided by ion beam 3 from low-energy broad-radiation ion source 2 . Here, the energy of the selenium ions can be selected between 10 and 500 eV.

[0039] The substrate holder is heated to a temperature between 400 and 550° C. during this coating step.

[0040] Through the setting of the metal evaporator 1 and the resulting ray guide area 4, and through the ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com