Combined plastic forming method of automobile hub and matching forming mold of automobile hub

A technology for plastic forming and automobile wheel hubs, which is applied in the field of forming molds, aluminum alloy or magnesium alloy automobile wheel hubs or disc-shaped parts combined forming, which can solve the problems of large mold size, many production processes and large equipment tonnage, etc. High precision and surface precision, easy operation, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

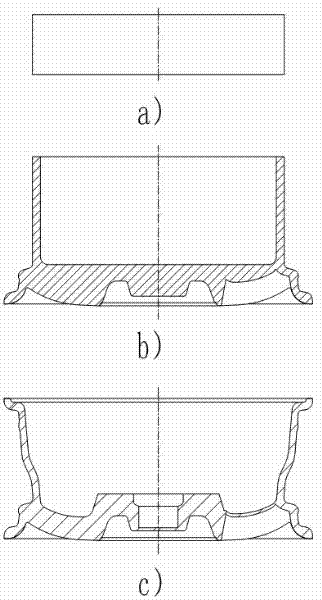

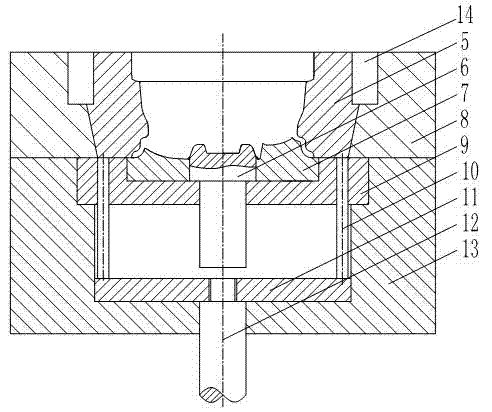

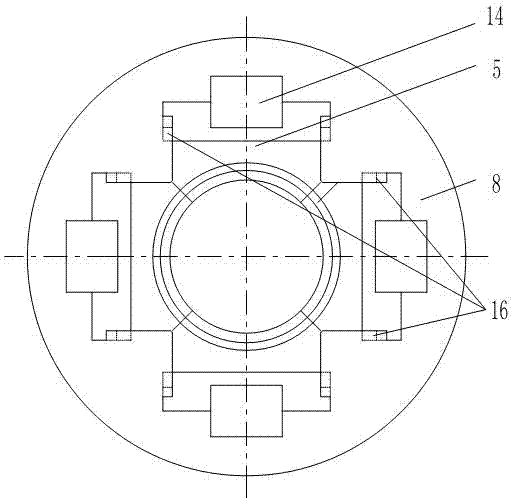

[0039] Embodiment one: if Figure 2 to Figure 5 As shown, the composite plastic forming mold for automobile wheel hub of the present invention comprises a flap closing type lower mold, and the flap closing type lower mold has a flap closing concave mold, and the flap closing concave mold is made up of more than two concave mold petal blocks 5. The lower part of the closing die is provided with a lower punch 7, and an ejector 6 is slidably inserted in the center of the lower punch 7. The petal closing die is jointly surrounded by the lower punch 7 and the ejector 6 when closing the mold. The mold cavity used for forming the wheel hub, the inner wall surface surrounded by the flap-closing die in the mold cavity matches the outer surface contour of the upper rim of the wheel hub to be formed, and the upper surface formed by the lower punch 7 and the ejector 6 is in line with the desired shape. The outline of the outer surface of the spokes of the formed wheel hub is consistent, a...

Embodiment 2

[0057] Embodiment two: if Figure 9 As shown, the difference between the second embodiment and the first embodiment is that each concave mold petal block 5 of the flap-closing die set in the flap-closing lower mold is installed on the lower mold base 13 through a horizontal slideway, and each concave mold What the mold opening and closing driving mechanism of transmission connection on the petal block 5 adopted is the drive cylinder 14 that is connected on the outer surface of each die petal block 5, and this drive cylinder 14 can adopt electric cylinder or hydraulic cylinder.

[0058]The combined forming method of the automobile hub of the present invention combines two forming processes of extrusion and bulging in one process and is formed in two steps through a set of forming dies, wherein the bottom surface of the extrusion upper punch 1 is a plane, and its outer peripheral surface A ring cavity for preforming the hollow tube blank structure is formed between the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com