Microbial agent for quickly degrading and reducing organic waste and application thereof

A technology of microbial agent and organic waste, which is applied to the reduction of organic waste, the screening of high-efficiency microbial agent for degrading organic waste, and the control of harmless treatment conditions. It can solve the problems of high cost and the technology has not reached the practical stage. , to achieve the effect of low unit energy consumption, small footprint and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

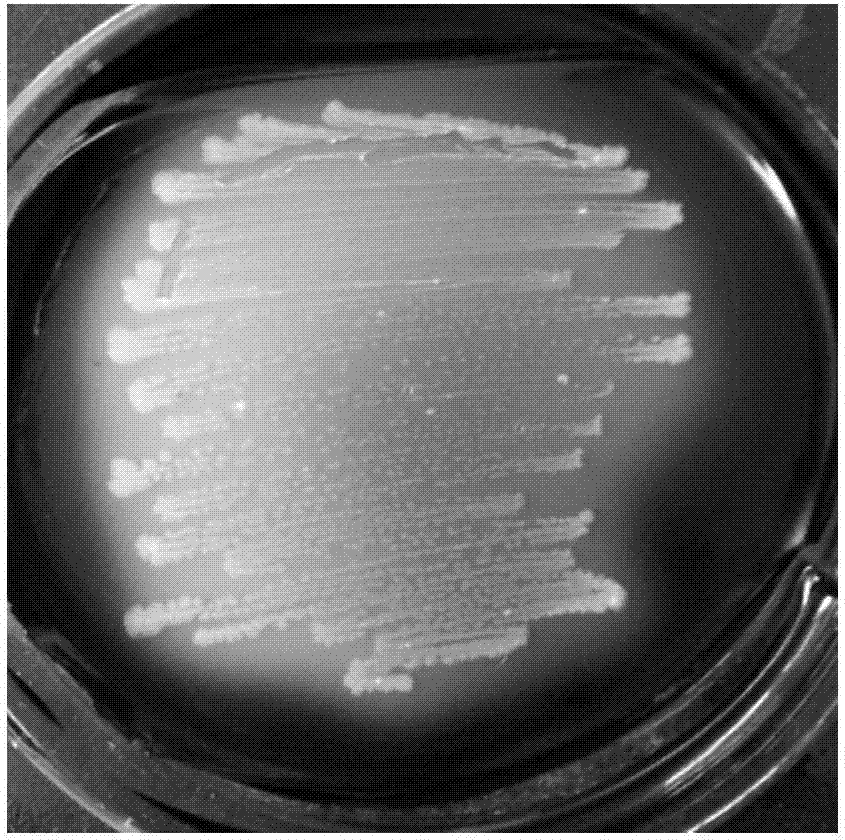

Image

Examples

Embodiment 1

[0051] A middle school canteen in Hangzhou processes about 0.5 tons of food waste per day. The treatment conditions are as follows:

[0052] The four screened bacteria were cultured separately in liquid LB medium, the culture conditions were pH 4.0, NaCl could reach 2.0%, the culture temperature was 35°C, 140 rpm, and after 3-6 days of shaker culture, the ratio of 1:1 : 1:1 volume ratio mixing.

[0053] The mixed bacterial agent is stirred with the rice bran, and it is easy to add into the reaction chamber without agglomeration. The microbial agent is added once every half month, and the amount of each addition is 0.4% (M / M) of the daily treatment amount of organic waste.

[0054] Before the addition of organic waste, large pieces of organic waste such as large bones and corn pieces need to be sorted out and crushed, and then added to the reaction chamber for degradation treatment.

[0055] Before adding organic waste, it needs to be press-filtered to control the water content...

Embodiment 2

[0062] The daily processing capacity of kitchen waste from various restaurants in a commercial complex in Hangzhou is about 0.3-0.8 tons. The biggest feature of this kitchen waste is its high oil content. According to the characteristics of this kitchen waste, the treatment conditions are as follows.

[0063] Cultivate the four screened bacteria separately in liquid LB medium, the culture conditions are pH 4.0, NaCl can reach 2.0%, culture temperature is 35°C, 140rpm, shaker culture for 3 to 6 days, degrade starch, protein The ratio of fat, cellulose is mixed according to the volume ratio of 1:1:4:1.

[0064] The mixed bacterial agent is stirred with the rice bran, and it is easy to add into the reaction chamber without agglomeration. The microbial agent is added once every half month, and the amount of each addition is 0.4% (M / M) of the daily treatment amount of organic waste.

[0065] Before the addition of organic waste, large pieces of organic waste such as large bones an...

Embodiment 3

[0073] A vegetable planting base in a certain village in Ruian, Zhejiang, has a daily processing capacity of 1-1.5 tons of discarded vegetables. The composition of discarded vegetables varies with the seasons throughout the year. In spring and summer, they are mainly common green leafy vegetables, and in autumn they contain bamboo shoots, corn stalks, etc. The processing conditions are as follows.

[0074] Cultivate the four screened bacteria separately in liquid LB medium, the culture conditions are pH 4.0, NaCl can reach 2.0%, culture temperature is 35°C, 140rpm, shaker culture for 3 to 6 days, degrade starch, protein The bacteria of fat, fat and cellulose are mixed according to the volume ratio of 1:1:1:6.

[0075] The mixed bacterial agent is stirred with the rice bran, and it is easy to add into the reaction chamber without agglomeration. The microbial agent is added once every half month, and the amount of each addition is 0.4% (M / M) of the daily treatment amount of org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com