High-elongation waterborne polyurethane waterproof coating and preparation method

A water-based polyurethane and waterproof coating technology, applied in the field of high-extension water-based polyurethane waterproof coating and preparation, high-stretch water-based polyurethane waterproof coating, can solve the problems of low elongation at break, high hard segment content, brittle polyurethane, etc., and achieve short production cycle. , improve the overall performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

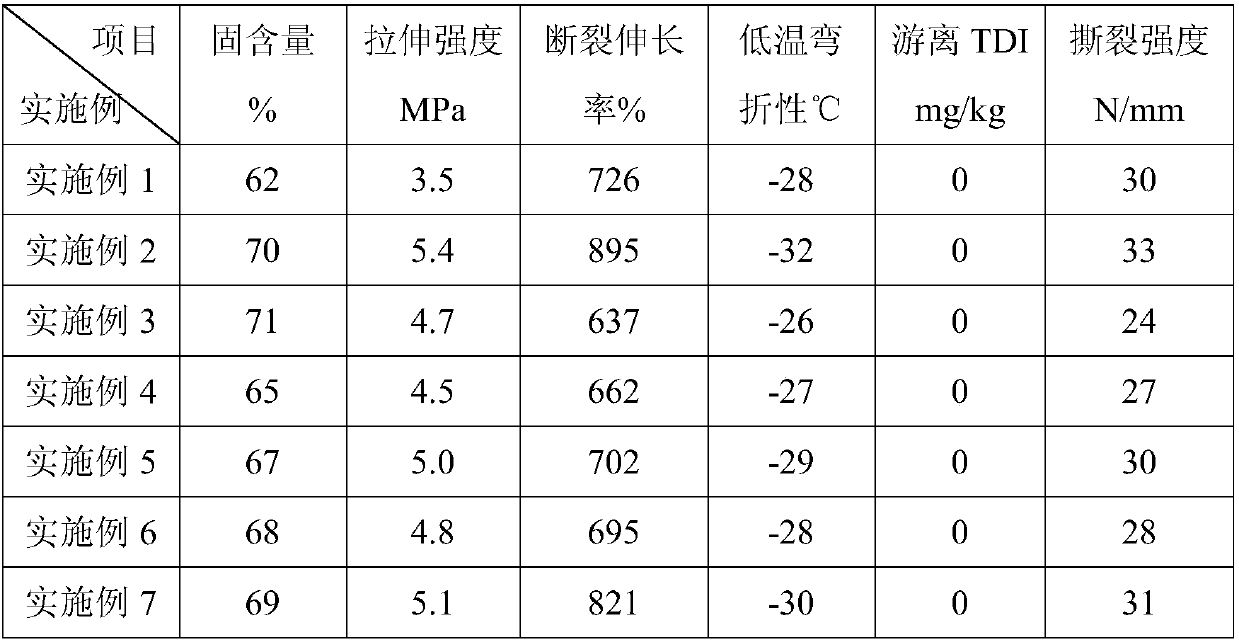

Examples

Embodiment 1

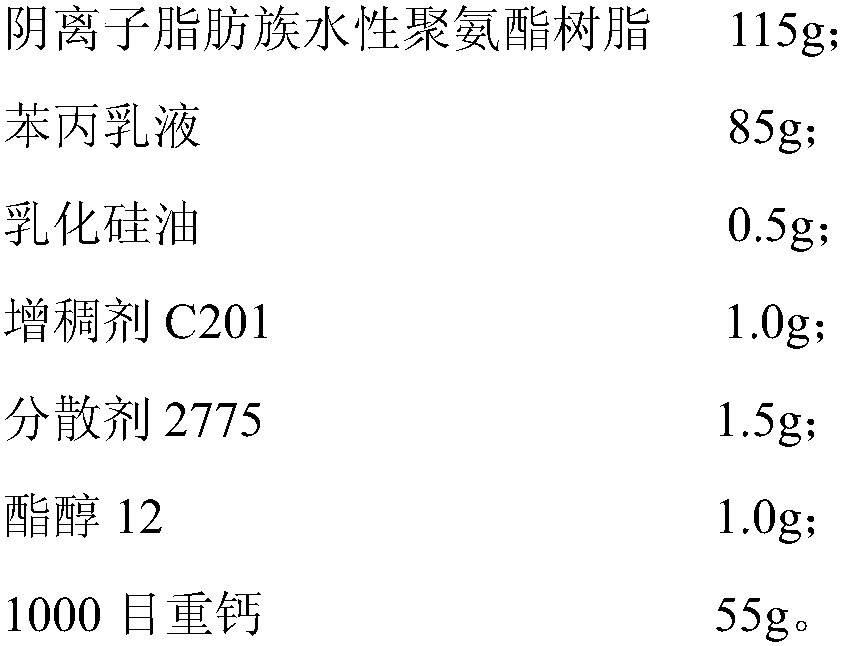

[0046] The preparation of water-based polyurethane waterproof coating, the proportion is as follows:

[0047]

[0048] The preparation method of the waterborne polyurethane waterproof coating described in embodiment 1, comprises the following steps:

[0049] Step 1: Accurately weigh the resin and emulsion in the formula and add them to the three-necked bottle, start stirring at a speed of 800r / min, and stir and pre-mix for 1 hour to obtain the first intermediate;

[0050] Step 2: Add a thickener, defoamer, dispersant, and film-forming aid to the first intermediate obtained in step 1, at a speed of 800 r / min, and stir and pre-mix for 1 hour to obtain the second intermediate;

[0051] Step 3: Add filler to the second intermediate obtained in Step 2 and disperse with high-speed stirring at a speed of 2000r / min, and stir for 2 hours to obtain a water-based polyurethane waterproof coating.

Embodiment 2

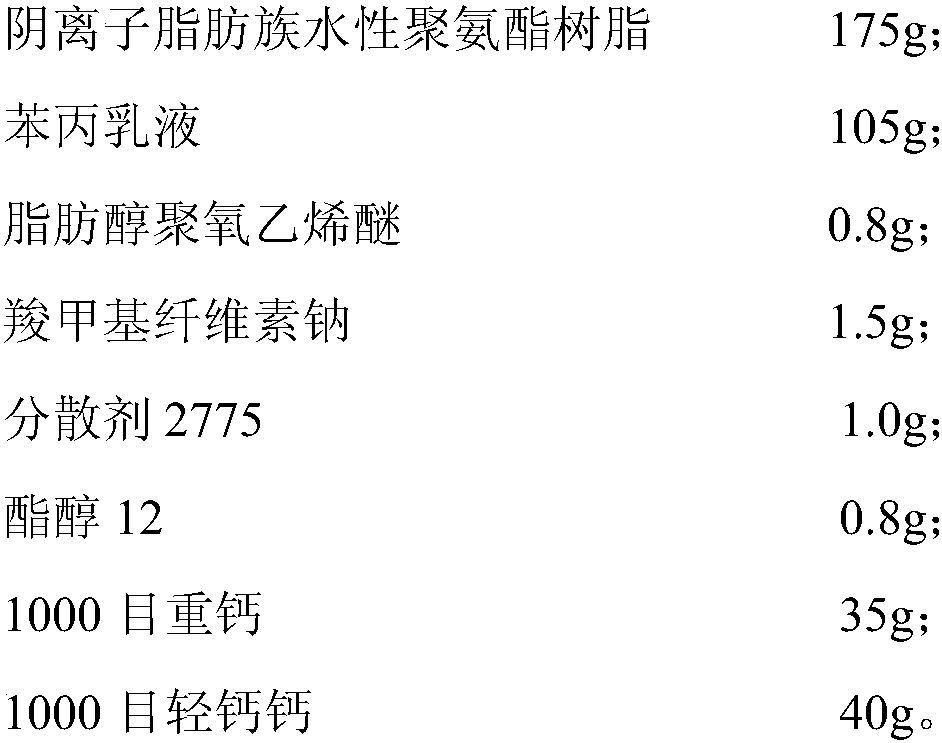

[0053] The preparation of water-based polyurethane waterproof coating, the proportion is as follows:

[0054]

[0055] The preparation method of the waterborne polyurethane waterproof coating described in embodiment 2, comprises the following steps:

[0056]Step 1: Accurately weigh the resin and emulsion in the formula and add them to the three-necked bottle, start stirring at a speed of 800r / min, and stir and pre-mix for 0.5h to obtain the first intermediate;

[0057] Step 2: Add a thickener, defoamer, dispersant, and film-forming aid to the first intermediate obtained in Step 1, at a speed of 800 r / min, and stir and pre-mix for 0.5 h to obtain the second intermediate;

[0058] Step 3: Add filler to the second intermediate obtained in Step 2 and disperse with high-speed stirring at a speed of 2000 r / min, and stir for 2.5 hours to obtain a water-based polyurethane waterproof coating.

Embodiment 3

[0060] The 1000 order heavy calcium 55g in embodiment 1 is changed into 1000 order light calcium 40g and 1000 order talcum powder 25g, other conditions are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com