Polycarboxylate superplasticizer for reducing viscosity of high-grade concrete and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylic acid water reducing agent and its preparation, can solve the problems of complicated production, long reaction time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

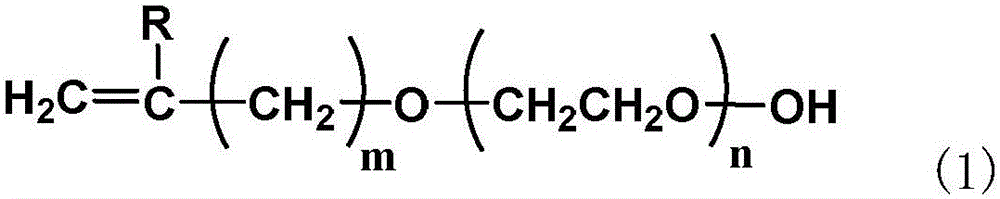

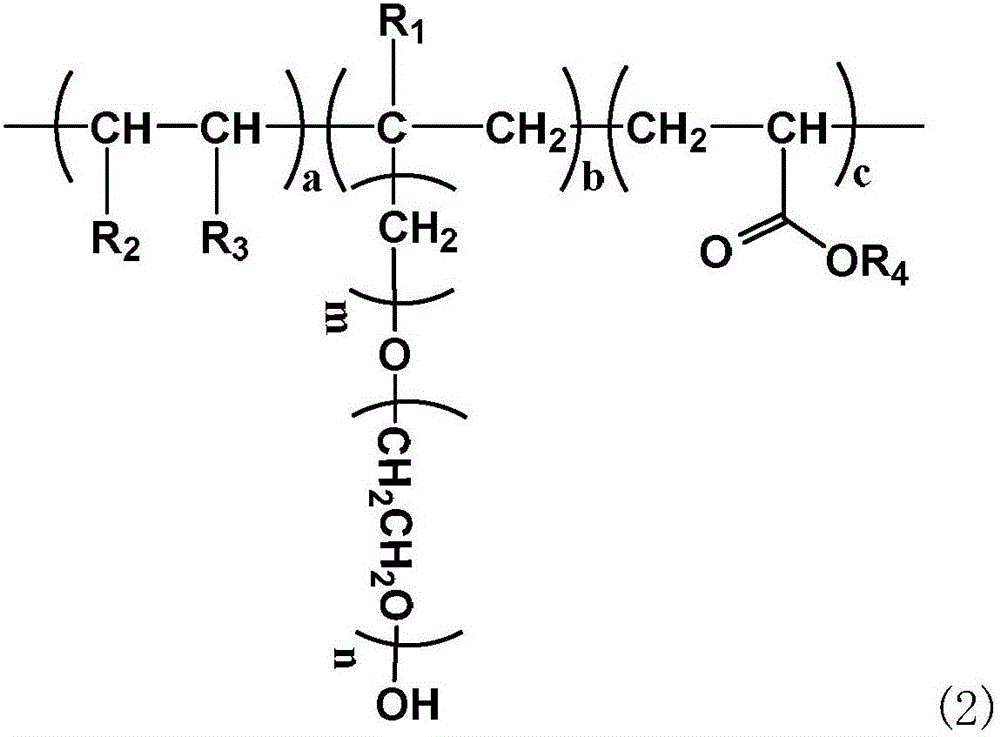

Method used

Image

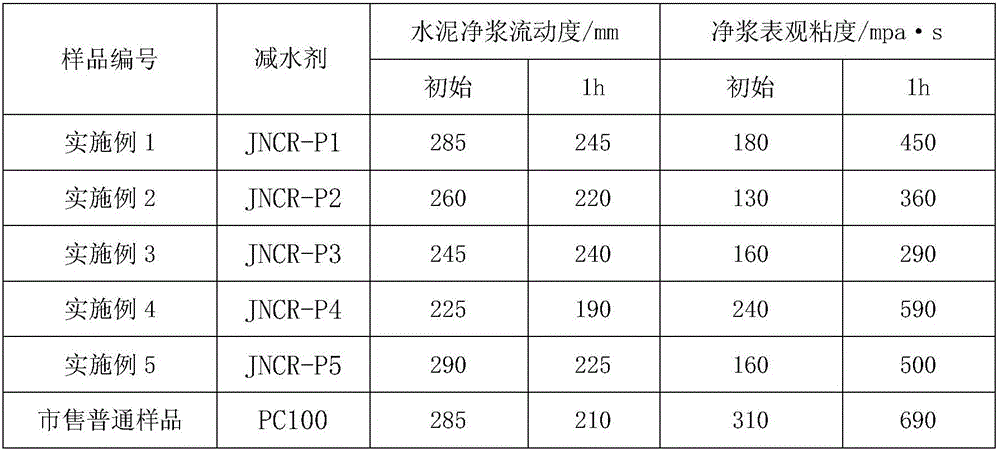

Examples

Embodiment 1

[0023] Stir 100 parts of methallyl polyoxyethylene ether, 15 parts of acrylic acid, 10 parts of hydroxyethyl acrylate, and 80 parts of deionized water at room temperature to completely dissolve the reactants, add 1.0 parts of ammonium persulfate, and after 15 minutes Add 0.5 parts of tartaric acid aqueous solution dropwise to the container, control the dropping speed, finish dropping within 2 hours, then add 5.5 parts of viscosity reducing agent propylene glycol, keep the temperature for 1 hour, and finally add 30% sodium hydroxide Adjust the pH of the solution to 7.0, and dilute it with water to obtain a liquid polycarboxylate high-performance water reducer with a solid content of 55% (it can also be diluted to any concentration by adding water), and the product JNCR-P1 is obtained.

Embodiment 2

[0025] 100 parts of isopentenyl polyoxyethylene ether, 10 parts of p-vinylbenzenesulfonic acid, 12 parts of hydroxypropyl acrylate, and 80 parts of deionized water were stirred at room temperature to completely dissolve the reactants, and 0.8 parts of azobisiso Butyronitrile, after 15 minutes, add dropwise an aqueous solution containing 0.3 parts of glucose to the container, control the rate of addition, and finish dropping within 2 hours, then add 4.5 parts of viscosity-reducing regulator glycerol, keep the temperature for 1 hour, and finally add 30 % sodium hydroxide solution to adjust pH=7.0, and dilute with water to obtain a 55% solid-containing liquid polycarboxylate high-performance water reducer (can also be diluted to any concentration with water), and the product JNCR-P2 is obtained.

Embodiment 3

[0027] Mix 100 parts of isohexenyl polyoxyethylene ether, 12 parts of p-vinyl benzoic acid, 14 parts of methyl acrylate, and 80 parts of deionized, and stir at room temperature to completely dissolve the reactants, add 1.0 parts of ammonium persulfate, and then add Add 0.5 parts of an aqueous solution of oxalic acid into the container dropwise, control the rate of addition, and finish dropping within 2 hours, then add 2.5 parts of viscosity-reducing agent 2-methyl-2-acrylamidopropanesulfonic acid, and keep the temperature for 1 hour. Finally, add 30% sodium hydroxide solution to adjust the pH=7.0, and dilute with water to obtain a liquid polycarboxylate high-performance water reducer with 55% solid content (it can also be diluted to any concentration by adding water), and the product JNCR-P3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com