Early strength type water reducing agent for precast concrete

A technology of precast concrete and water reducing agent, applied in the field of early strength water reducing agent, can solve the problems of rising production cost, low water reducing rate and alkali content, and rapid loss of concrete slump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

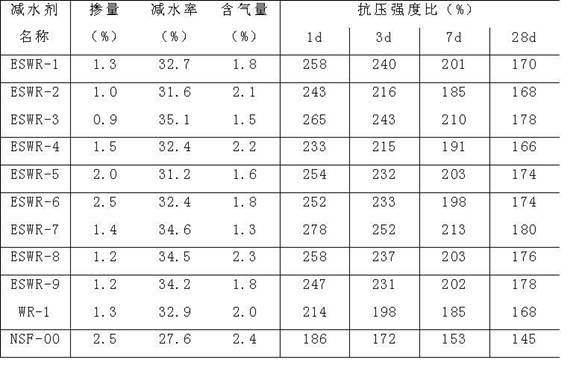

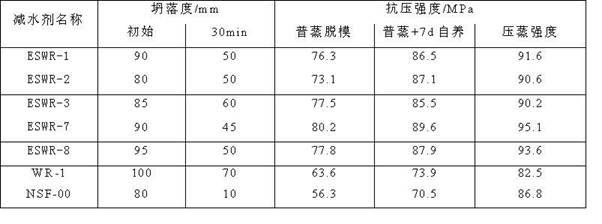

Examples

Embodiment 1

[0022] Weigh 53.80kg of water and place it in a reaction kettle, then add 1.00kg of lithium sulfate and 5.00kg of sodium nitrate successively under stirring, and add 40.00kg of 40% solid content polycarboxylate water reducer (VIVID- 500 (D type), weight average molecular weight 31200, produced by Shanghai Sanrui Polymer Material Co., Ltd.), then add 0.20kg polysiloxane defoamer BYK-065, and continue to stir evenly to obtain the early strength type of the present invention Water reducer, recorded as ESWR-1.

Embodiment 2

[0024] At room temperature, weigh 38.40kg of water and place it in a reaction kettle, then add 0.50kg of lithium nitrate, 3.00kg of sodium thiocyanate and 8.00kg of calcium nitrate under stirring, and add 50.00kg of 40% solid content after the inorganic salt is completely dissolved Polycarboxylate superplasticizer (VIVID-500 (type A), weight average molecular weight 39,000, produced by Shanghai Sanrui Polymer Material Co., Ltd.), then add 0.10kg of silicone oil defoamer TEGO Antifoam 204, continue to stir evenly That is, the early-strength water reducer of the present invention is obtained, which is designated as ESWR-2.

Embodiment 3

[0026] At room temperature, weigh 32.85kg of water and put it in the reaction kettle, then add 2.00kg of lithium carbonate and 5.00kg of sodium sulfate in turn under stirring, and add 60.00kg of polycarboxylate water reducer with 40% solid content after the inorganic salt is completely dissolved (VIVID-500 (Type C), weight average molecular weight 39000, produced by Shanghai Sanrui Polymer Material Co., Ltd.), then add 0.15kg of polyether modified silicone defoamer LM-110, and continue stirring to obtain this The invented early-strength water reducer is designated as ESWR-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com