A cement-based shrinkage-free grouting material doped with phosphorus slag powder and a using method thereof

A technology of grouting materials and phosphorus slag powder, which is applied in the field of building materials, can solve the problems of occupying large land, polluting soil and water bodies, etc., and achieve the effect of improving early strength, increasing early strength, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

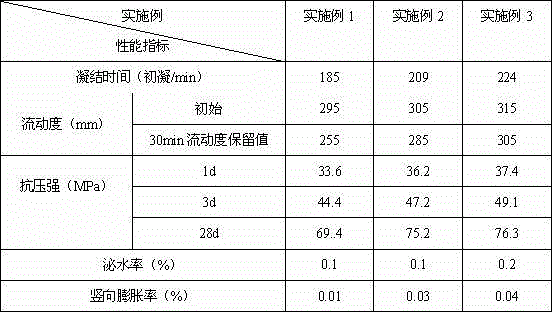

[0052] Example 1, a cement-based non-shrinkage grouting material mixed with phosphorus slag powder, according to ordinary Portland cement 100, phosphorus slag powder 10, ultrafine slag powder 20, desulfurized gypsum 5, medium sand 200, fine sand 100, Expanding agent 2, sepiolite powder 2, water reducer 0.05, defoamer 0.05, water retaining agent 0.02 by weight. According to 15% of the total weight of the non-shrinkage grouting material, add water and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0053] Example 2, a cement-based non-shrinkage grouting material mixed with phosphorus slag powder, according to ordinary Portland cement 100, phosphorus slag powder 30, ultrafine slag powder 40, desulfurized gypsum 10, medium sand 300, fine sand 150, Expanding agent 4, sepiolite powder 4, water reducing agent 0.50, defoaming agent 0.10, water retaining agent 0.04 are prepared by weight ratio. According to 20% of the total weight of the non-shrinkage grouting material, add water and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0054] Example 3, a cement-based non-shrinkage grouting material mixed with phosphorus slag powder, according to ordinary portland cement 100, phosphorus slag powder 40, ultrafine slag powder 50, desulfurized gypsum 15, medium sand 350, fine sand 250, Expanding agent 8, sepiolite powder 6, water reducer 2.50, defoamer 0.50, water retaining agent 0.10 weight ratio prepared. According to 25% of the total weight of the non-shrinkage grouting material, add water and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

[0055]

[0056] Table 1 Example performance test results

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com