Preparation method for comb-shaped copolymer cement dispersant, monomer used therein and prepared comb-shaped copolymer cement dispersant

A technology of cement dispersant and comb copolymerization, which is applied in the field of preparation of comb copolymer cement dispersant, which can solve the problems of cumbersome steps, environmental pollution and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

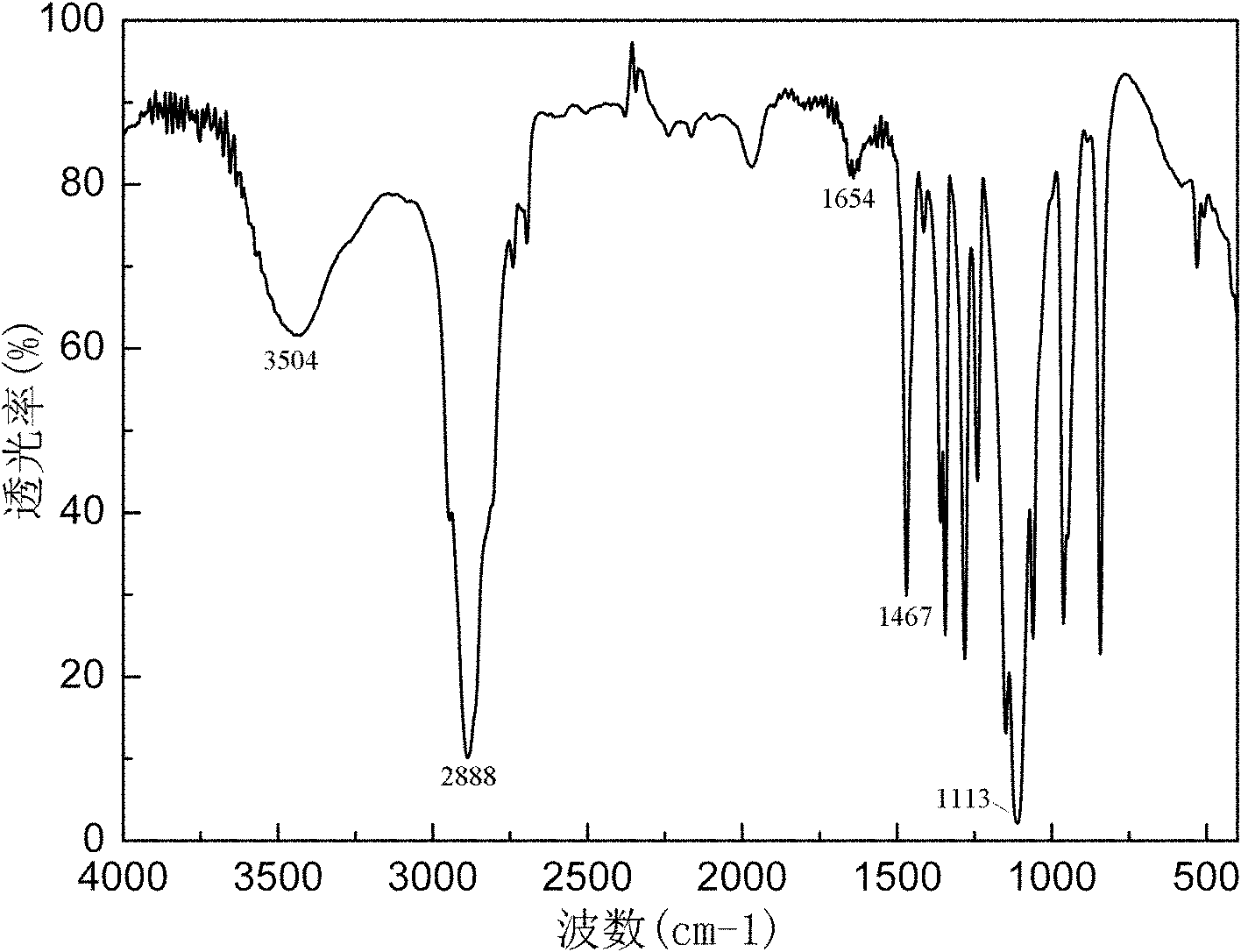

[0055] Preparation of branched living macromonomer

[0056] 58g of allyl alcohol is placed in a four-necked flask with a reflux condenser, a thermometer, a nitrogen conduit and a stirrer, 23g of sodium metal is added, and nitrogen bubbling is continuously carried out in the reaction flask, stirred at normal temperature until dissolved, and then Raise the temperature to 120°C, slowly add 74g of glycidol dropwise for 6 hours, keep it warm for 2 hours, and cool to obtain Intermediate 1.

[0057] 33g of intermediate 1 was placed in a 2L dry stainless steel autoclave, and the autoclave was sealed. After evacuating the reactor, replace the air in the reactor with nitrogen three times, raise the temperature to 120°C, and keep the reactor continuously vacuumed for 30 minutes, then stop, then continuously and slowly feed 990g of ethylene oxide, keeping the temperature at 120°C and the pressure of 0.2MPa , react until the pressure no longer drops, evacuate to -0.08MPa, maintain for 30m...

Embodiment 1

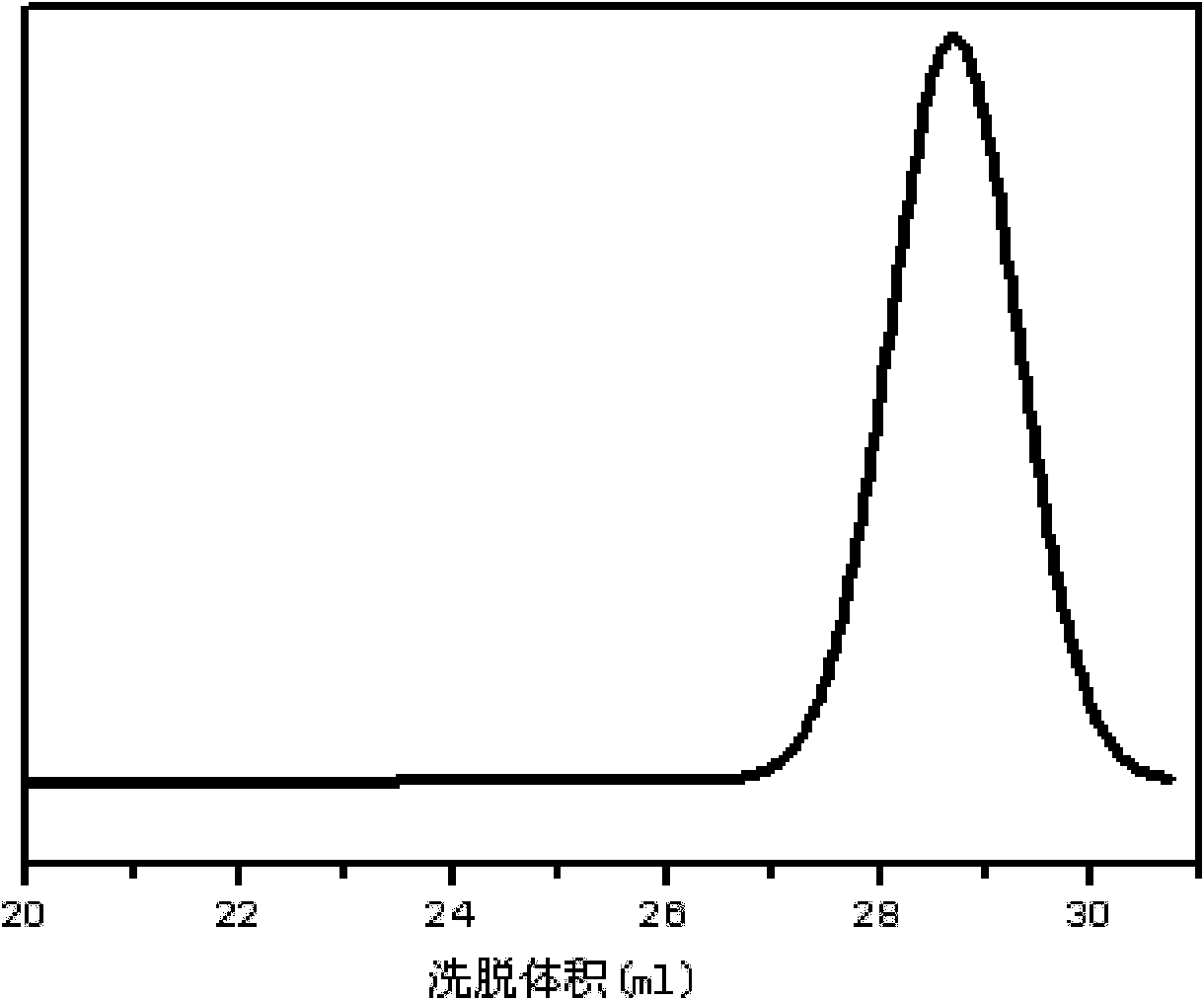

[0084] In a 1L glass reactor equipped with a thermometer, stirrer, dropping funnel and nitrogen conduit, add 300g of water, add 200g of branched active macromonomer 1, stir and heat up to dissolve, and purge the reaction vessel with nitrogen, and heat up to 90°C , and then 17.4g maleic acid, 0.22g 3-mercaptopropionic acid and 80g water were mixed and stirred to make a uniform aqueous monomer solution, which was added dropwise to the reactor at a constant speed for 4 hours, while 80g was added dropwise at a constant speed The initiator aqueous solution containing 1.62g of potassium persulfate, the dropping time is 4.5h, after the whole solution is added dropwise, continue to keep warm for 8h, then cool down to 50°C, add sodium hydroxide to neutralize to pH=7.5, and the obtained solid content is 32.2 % transparent liquid, the molecular weight of the copolymer is 37,600, and the conversion rate of branched active macromonomer 1 is 90.2%.

Embodiment 2

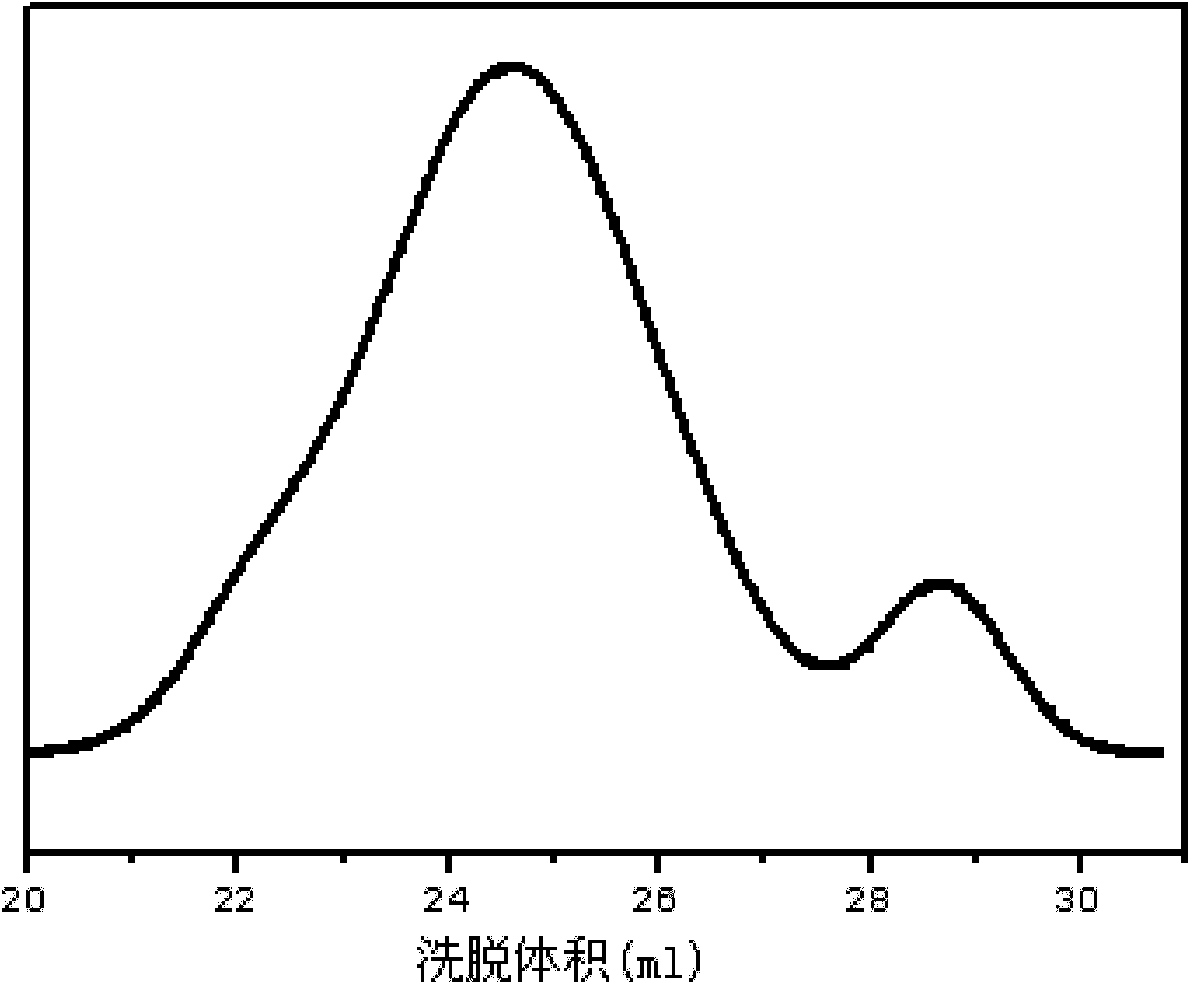

[0086]In a 1L glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, add 200g of water, add 200g of branched active macromonomer 2, stir and heat up to dissolve, and purge the reaction vessel with nitrogen, and heat up to 95°C , and then 24.8g of acrylic acid, 1.61g of 2-mercaptopropionic acid and 80g of water were mixed and stirred to form a uniform monomer aqueous solution, which was added dropwise to the reactor at a constant speed for 2 hours, and 50g containing 4.33 The initiator aqueous solution of g ammonium persulfate, the dropping time is 2.5h, continue to keep warm for 4h after the whole solution is added dropwise, then cool down to 50°C, add potassium hydroxide to neutralize to pH=7.5, and obtain a solid content of 42.5%. Transparent liquid, the molecular weight of the copolymer is 22,300, and the conversion rate of branched active macromonomer 2 is 93.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com