Method for recovering oil gas and device

A recovery method and technology for oil and gas, applied in separation methods, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increasing the operating cost of the combined condensation-adsorption process, local overheating of the activated carbon bed, and reducing the service life of the adsorbent, etc. Achieve the effect of reducing the scale of subsequent processing units, eliminating potential safety hazards, and reducing volatilization of oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

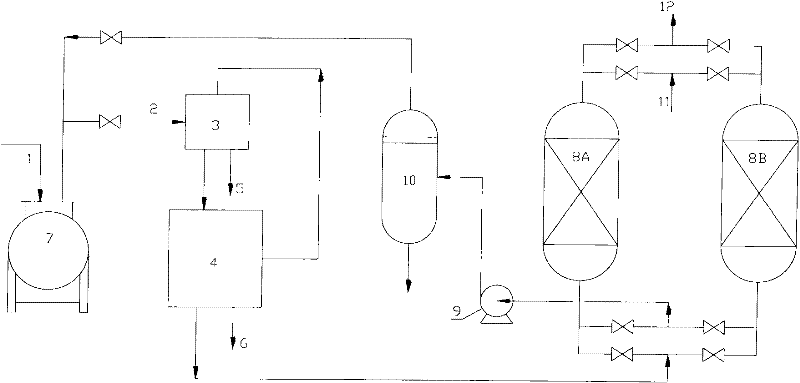

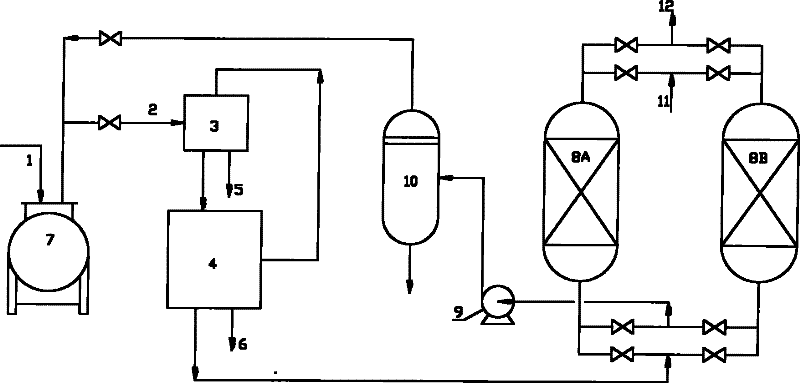

[0027] Such as figure 1 As shown, in the oil and gas recovery method of the present invention, oil gas 2 is collected and cooled by cooling device 3 through heat exchange, cooling device condensate 5 is recovered, and the cooled oil gas enters condensing device 4, and part C in the oil gas is 2 and most of the C 3 and the above hydrocarbon components are condensed, and the condensate 6 of the condensing unit is recovered. The uncondensed oil gas returns to the cooling device 3 as the cooling medium of the cooling device 3 . The uncondensed oil gas enters the adsorption tower 8 to absorb the oil gas after being exchanged by the cooling device 3, and the adsorption tail gas 12 is discharged up to the standard. At least two adsorption towers 8 are provided for switching operation. The saturated adsorption tower 8 is desorbed and regenerated by a vacuum pump 9 , and the regenerated oil gas desorbed by vacuum is sent to the desorbed oil gas storage tank 10 . When the oil product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com