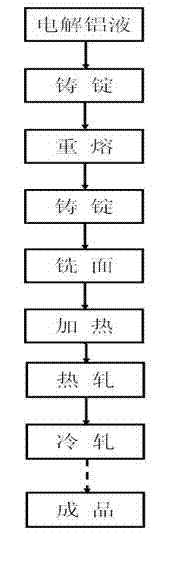

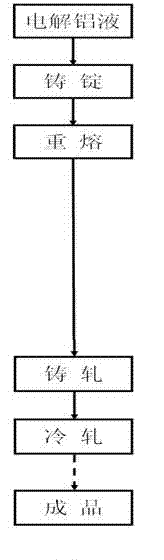

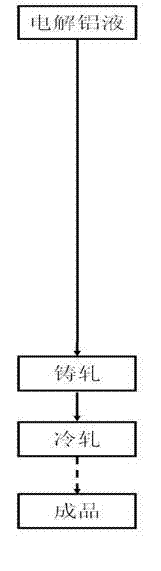

Method for producing ultra-wide and ultra-thin cast-rolled aluminium foil blanks by directly cast-rolling blanks with electrolytic aluminium liquid

A technology of electrolytic aluminum liquid and ultra-thin aluminum foil, which is applied in the direction of metal rolling and process efficiency improvement, and can solve problems such as large cooling intensity and cooling gradient, poor surface quality of cast-rolled foil billets, and poor high-temperature characterization of the melt. Achieve the effects of less air content, shortened production process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation schemes of the two alloys of 1145 and 1235 are used below to illustrate the relevant process parameters of the whole process of casting and rolling double-zero aluminum foil billets by using aluminum ingots.

[0012] 1. Alloy: 1145 and 1235, the details can be determined according to the production requirements.

[0013] 2. Chemical composition:

[0014] 1145: Si+Fe≤0.55;Cu:0.05;Mn:0.05;Zn:0.05;V:0.05;Ti:0.03;other individual≤0.03;Al 99.45, percentage content; 0.05; Mn: 0.05; Zn: 0.10; V: 0.05; Ti: 0.06; other individual ≤ 0.03; aluminum 99.35, percent content. Those whose content has upper and lower limits are alloy elements; those whose content is a single value, aluminum is the lowest limit, and other impurity elements are the highest limit. Specific: Fe (0.36-0.41)% in 1145; Si≤0.08% (according to the composition in primary aluminum), Fe (0.41-0.45)% in 1235; Si (0.10-0.12)%.

[0015] (1) Casting and rolling

[0016] The casting a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com