Early-strength polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of preparation of early-strength polycarboxylate high performance water reducer and water reducer, and can solve the problem of reducing the water reducing performance of polycarboxylate water reducer and concrete There are negative effects on the later strength, and the early strength effect is not obvious, etc., to achieve the effect of good early strength effect, short setting time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

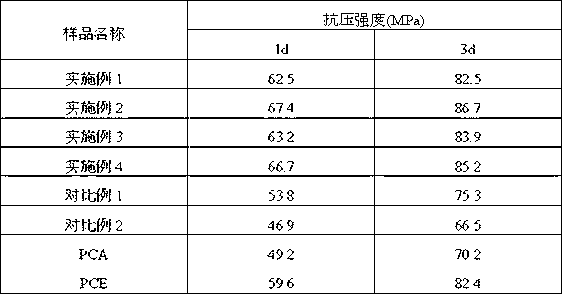

Examples

Embodiment 1

[0023] Add 310 parts of methallyl polyoxyethylene ether (M W =3000), 4.8 parts of lauryl alcohol and 8 parts of sodium methacrylate, and add 220 parts of water, heat up to 30°C and stir to make it all dissolve in water, heat up to 50°C and add 5.2 parts of tert-butyl hydrogen peroxide and stir Uniform; at the same time, add dropwise a mixed aqueous solution made of 7.8 parts of dihydroxyethylethylenediamine, 48 parts of methacrylic acid and 120 parts of water and a mixed solution made of 1.2 parts of ascorbic acid, 3.2 parts of 3-mercaptopropionic acid and 100 parts of water. Mix the aqueous solution and complete the dropwise addition within 3.5 hours; after the addition, keep at 50°C and continue stirring for 1 hour; after cooling down to room temperature, add 42 parts of liquid caustic soda and 120 parts of water and stir well.

Embodiment 2

[0025] Add 344 parts of methallyl polyoxyethylene ethers (M W =5000), 3 parts of lauryl alcohol and 6.2 parts of sodium allyl sulfonate, and add 220 parts of water, heat up to 30°C and stir to make it all dissolve in water, heat up to 50°C and add 4.5 parts of hydrogen peroxide and stir evenly; Add dropwise a mixed aqueous solution made of 6.4 parts of tetrahydroxyethylethylenediamine, 23 parts of acrylic acid and 120 parts of water and a mixed aqueous solution made of 1.8 parts of ascorbic acid, 2.4 parts of thioglycolic acid and 100 parts of water, dropwise within 3.5 hours Complete; after the addition, keep at 50°C and continue to stir for 1h; after cooling down to room temperature, add 32 parts of liquid caustic soda and 140 parts of water and stir evenly.

Embodiment 3

[0027] Add 330 parts of methallyl polyoxyethylene ether (M W =5000), 6 parts of lauryl alcohol and 6 parts of sodium allyl sulfonate, and add 220 parts of water, heat up to 30°C and stir to make it all dissolve in water, heat up to 50°C and add 4.4 parts of hydrogen peroxide and stir evenly; Add dropwise a mixed aqueous solution made of 7 parts of dihydroxypropyl ethylenediamine, 28 parts of acrylic acid and 120 parts of water and a mixed aqueous solution made of 2.2 parts of ascorbic acid, 3 parts of mercaptoethanol and 100 parts of water, dropwise within 3.5 hours Complete; after the addition, keep at 50°C and continue to stir for 1 hour; after cooling down to room temperature, add 45 parts of liquid caustic soda and 125 parts of water and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com