Process for preparing modified naphthalene series water reducing agent

A naphthalene-based water reducer and modification technology, which is applied in the preparation of modified naphthalene-based water reducers, the preparation process of dispersants and oilfield chemicals, and the preparation of concrete admixtures. High cost, environmental pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

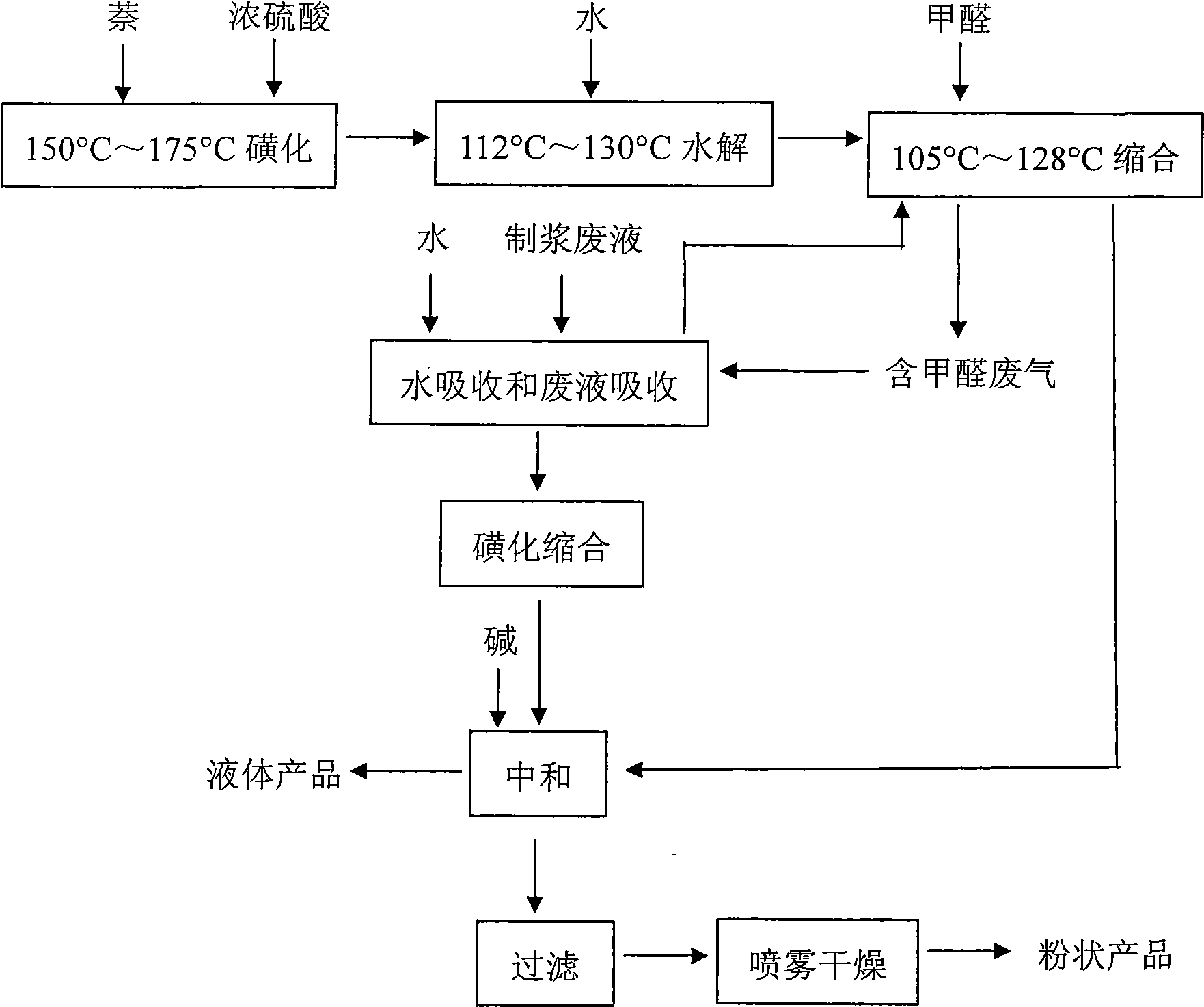

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] A preparation method of a modified naphthalene-based water reducer, the steps of which are:

[0022] A. Add industrial naphthalene to a glass-lined reactor and melt to 110 or 120 or 135 or 146 or 156 or 161 or 168 or 172 or 175°C, add industrial concentrated sulfuric acid, and heat it at 150 or 156 or 160 or 164 or 169 or 173 or React at 175°C for 2 to 3 hours;

[0023] B. Sampling and measuring the acid value is 28% to 34%, determine the amount of water to be added for the hydrolysis reaction, lower the temperature to 112 or 114 or 116 or 120 or 124 or 127 or 130°C and add water to hydrolyze for 0.5 to 1.5 hours;

[0024] C. Cool down to 88 or 90 or 93 or 96 or 99 or 102 or 107 or 110°C and add industrial formaldehyde for condensation reaction, condensation reaction temperature 105 or 108 or 111 or 116 or 119 or 124 or 126 or 128°C, time 4 or 5 or 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com