Recording apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

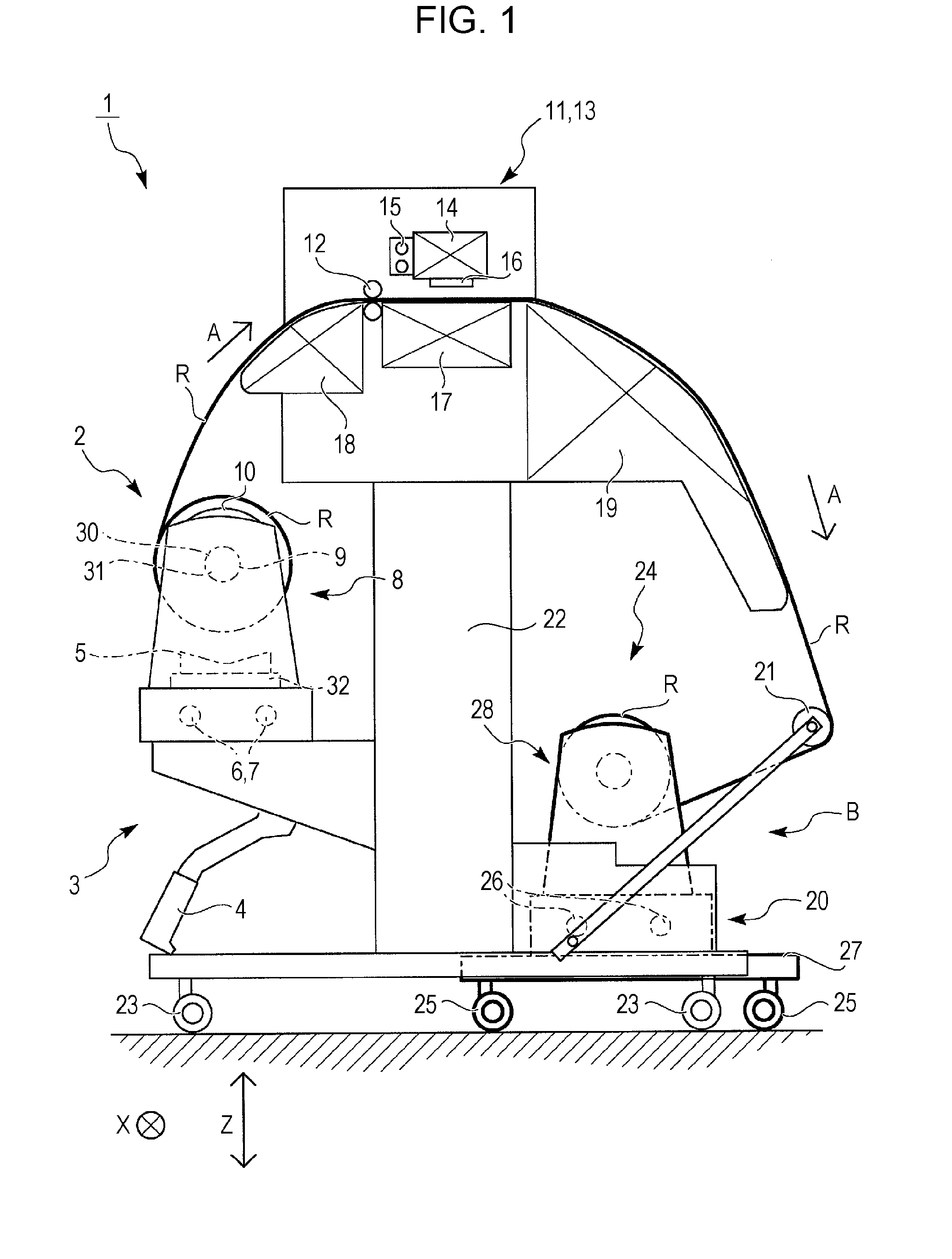

[0028]Hereinafter, embodiments of the invention are described with reference to the drawings.

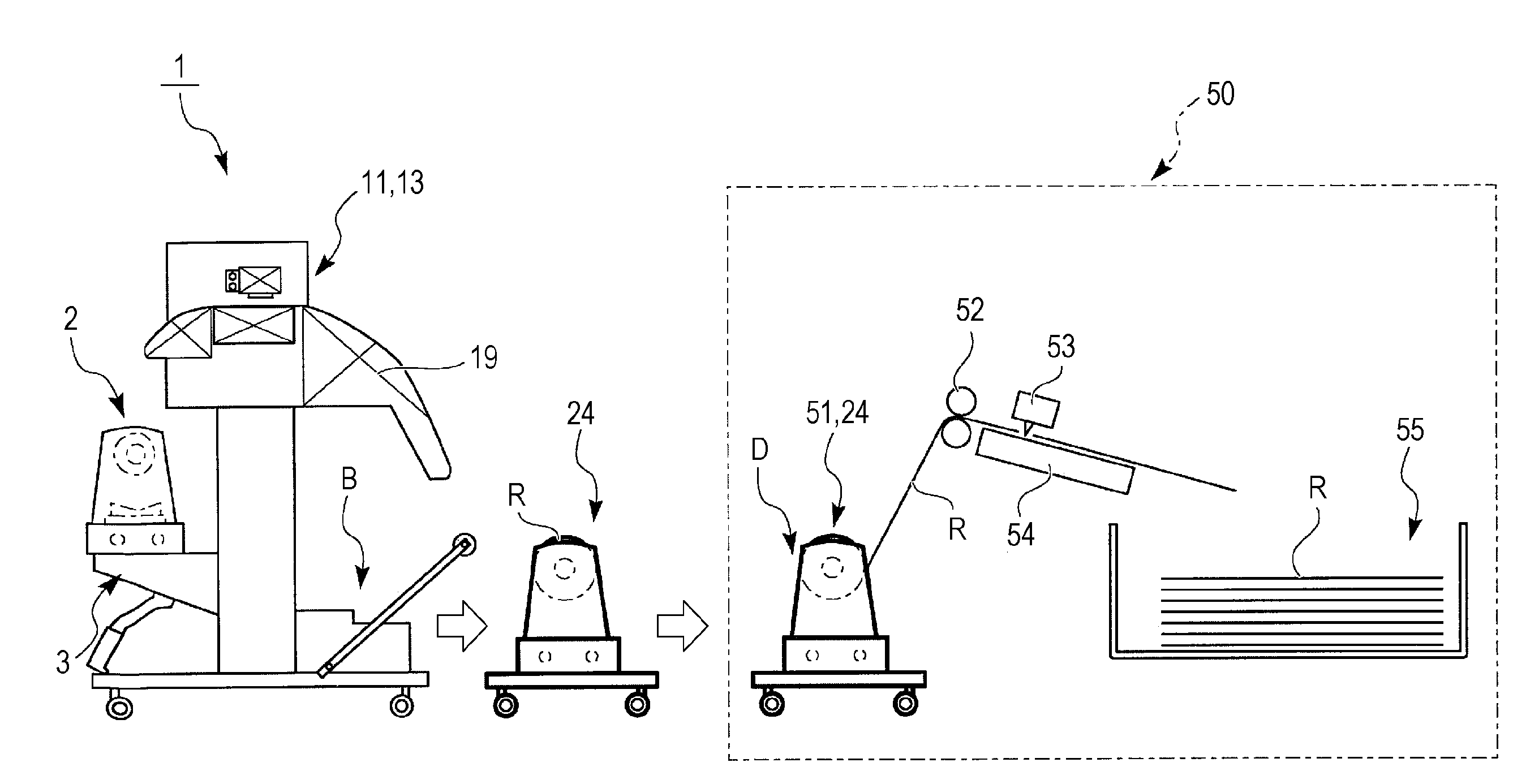

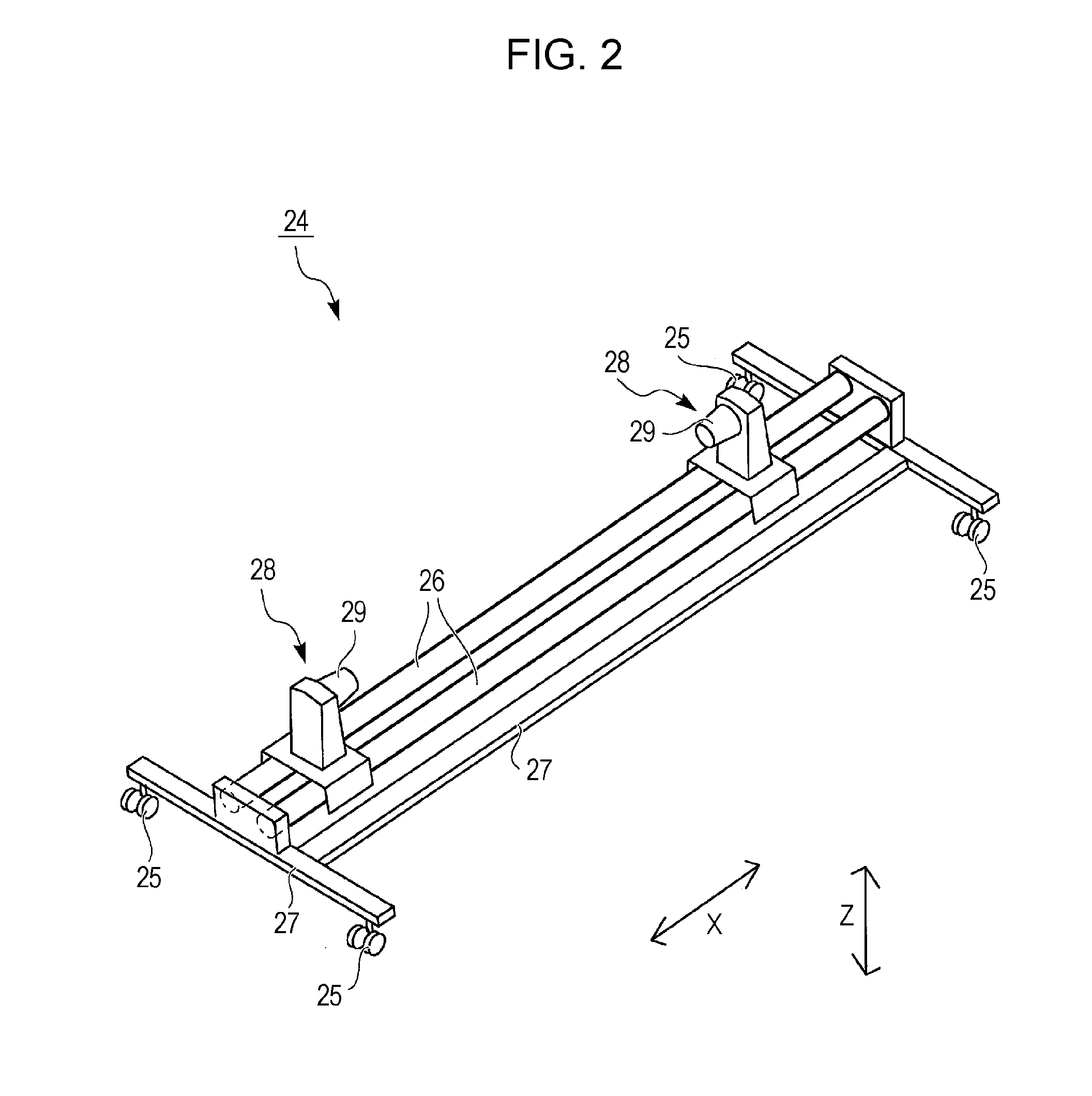

[0029]FIG. 1 is a side cross-sectional view schematically showing the entire configuration of a large-sized ink jet printer 1 (hereafter, simply referred to as a printer) as a recording apparatus of an embodiment.

[0030]As shown in FIG. 1, the printer 1 includes a feeding unit 2, a recording unit 13, and a winding device 24. The feeding unit 2 in the components can release and send out a roll medium R wound in a roll in the transport direction A. In detail, the feeding unit 2 includes a first holder unit 8 and a pair of rollers 12.

[0031]In these components, the first holder unit can retain both ends of the roll medium R to be rotatable. The first holder unit 8 includes a first shaft 9 fitted in a core hole 31 of a roll core 30 of the roll medium R and a flange 10 that can come in contact with an end of the roll medium R. The first shaft 9 may freely rotate or may be driven by power of a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com