Winding device of slitter

一种卷绕装置、纵切机的技术,应用在卷绕条材、运输和包装、薄料处理等方向,能够解决重量增加、操作不便、无法准确卷绕卷筒材料等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

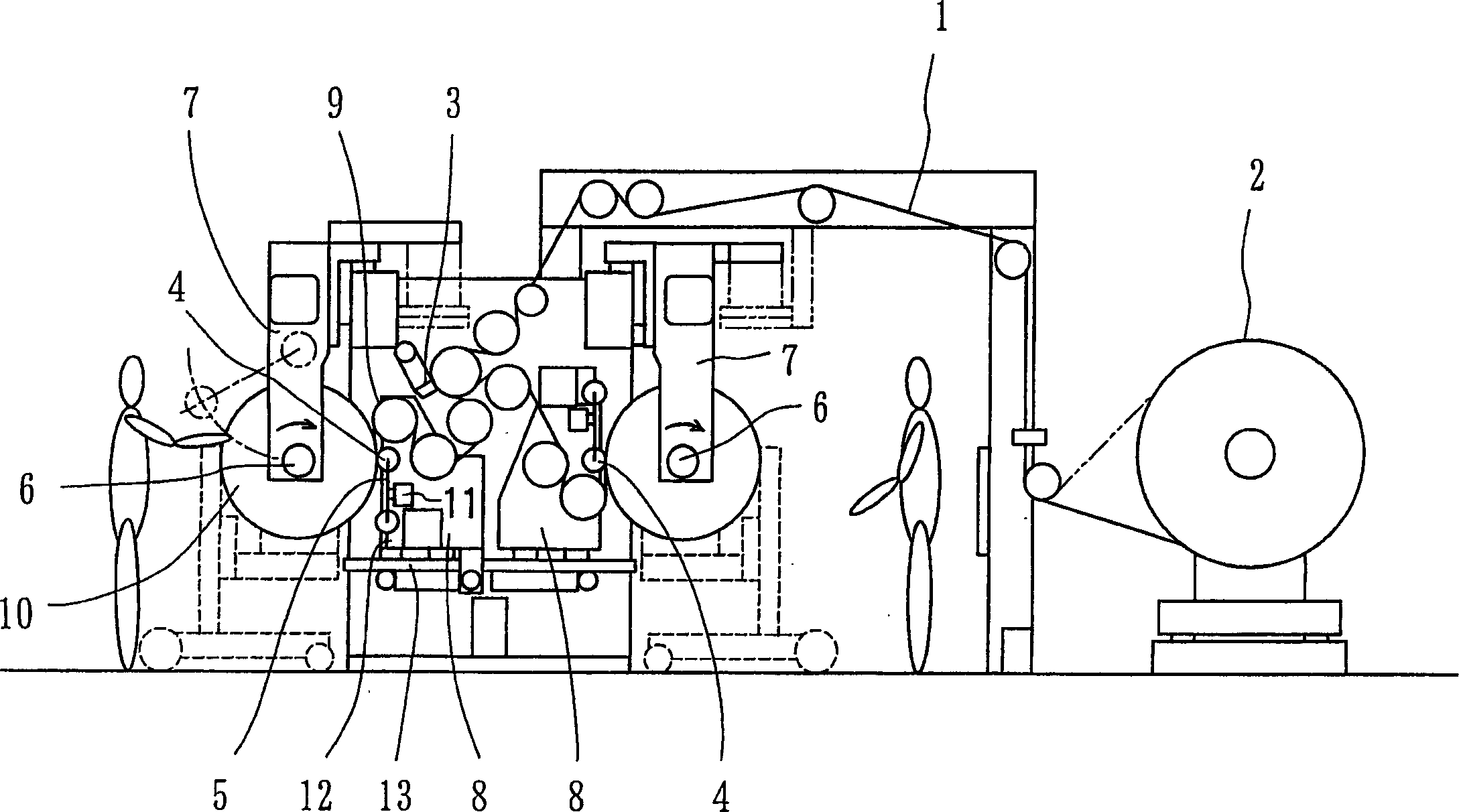

[0019] figure 1 represents the device of the present invention. This device is a winding device of a slitting machine. A roll material 1 such as a plastic film is unwound from a cylinder 2, introduced into a slitting knife 3, and slit into multiple strips. This point is different from that of the conventional slitting machine. The device is the same. The front and rear sides of the slitter are provided with a pair of winding devices, and the roll material 1 is guided to each winding device after being slitted, which is also the same as the conventional device.

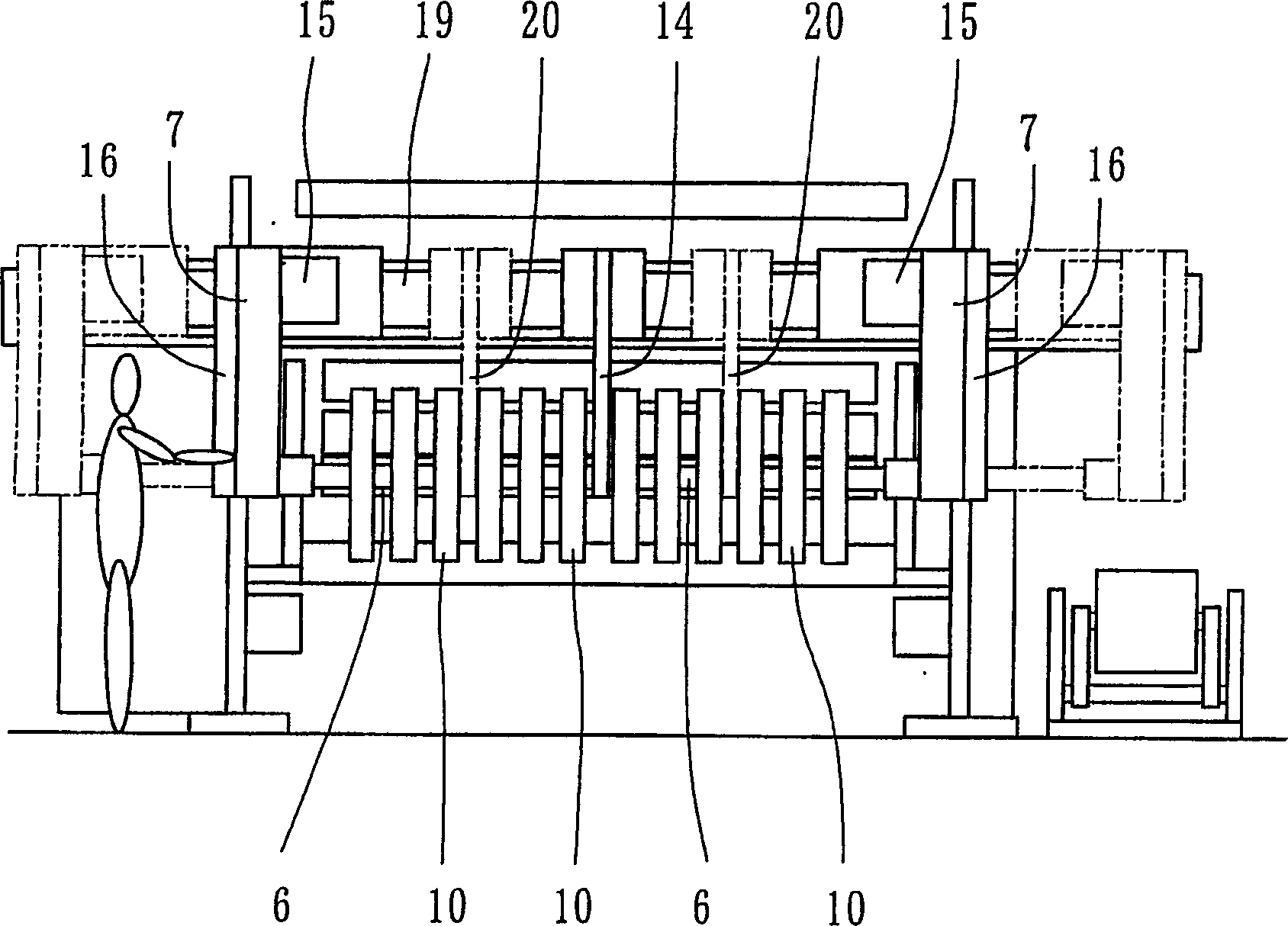

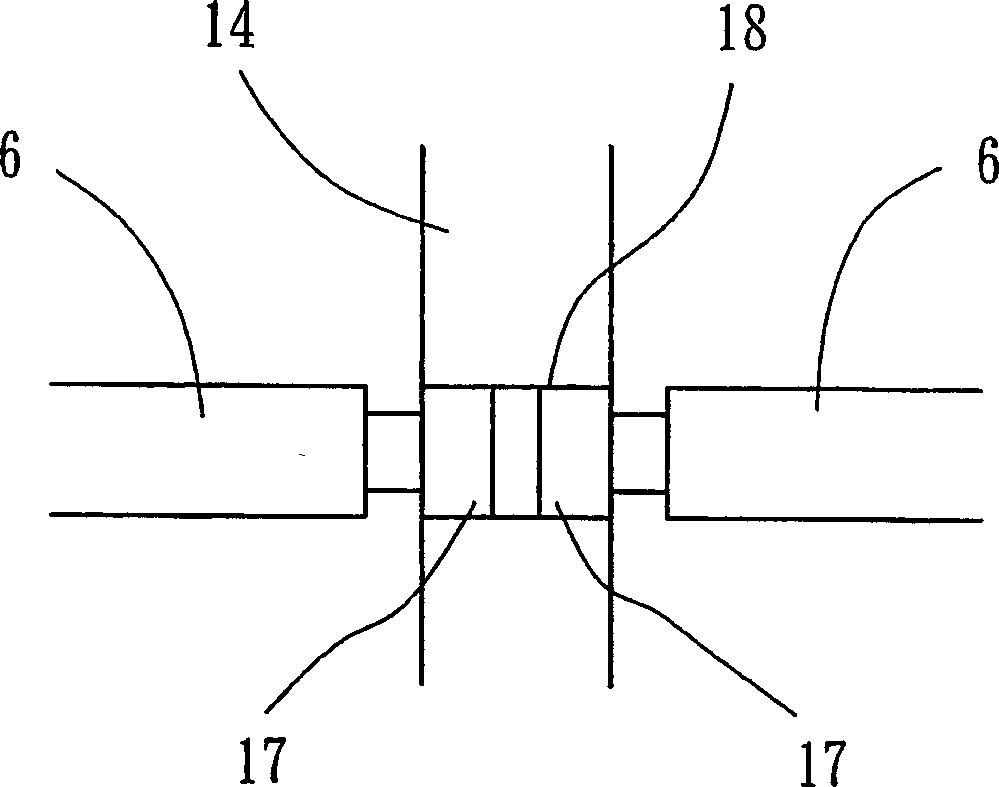

[0020] And, in each winding device, the touch roller 4 is supported by the front end of the arm 5, as figure 2 As shown, the winding shaft 6 is disposed between a pair of side plates 7 and is supported by the two side plates 7. After the roll material 1 is cut, the roll material 1 passes through the guide roller 9 of the movable stand 8 Guided by the contact roller 4 and the winding shaft 6, it is wound on the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com