Automatic rope arrangement control device for roller

A technology of control device and automatic discharge, which is applied in hoisting device, clockwork mechanism, etc., can solve the problems of large hydraulic volume efficiency error and complicated system, and achieve the effect of precise winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

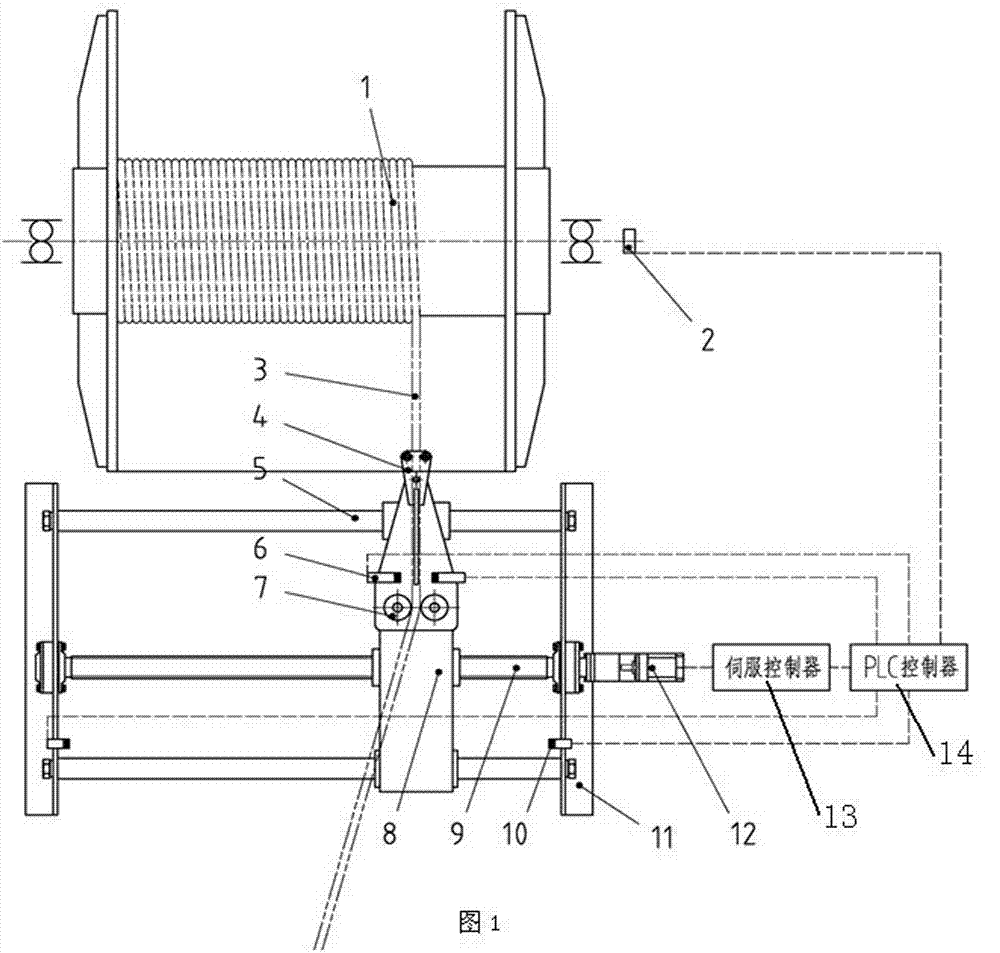

[0014] Depend on figure 1 It can be known that the drum automatic rope arranging control device of the present invention is used in conjunction with the drum 1, and includes a rope arranging device bracket 11, a PLC controller 14 and a servo controller 13. Motor 12, leading screw 9, guide rail 5, mobile support 8, guide rope pulley 7, deviation correction frame 4, deviation correction switch 6 and reversing switch 10. The deviation correction frame 4, the deviation correction switch 6 and the rope guide wheel 7 are installed on the mobile support 8, and the mobile support 8 drives the leading screw 9 by the servo motor 12, so that the mobile support 8 moves left and right on the guide rail 5. The deviation correction frame 4 is triangular in shape, and its upper end is hinged on the mobile support 8. There is a lever fixed on the deviation correction frame 4. The direction of the lever is set in the same direction as the wire rope. When the steel wire rope deviates, the deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com