Stator fixture mechanism for half-iron-core stator pin-type winding machine

A technology of iron core stator and winding machine, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc. It can solve the problems of not having to deal with the end of the line, large horizontal volume, and inability to realize winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

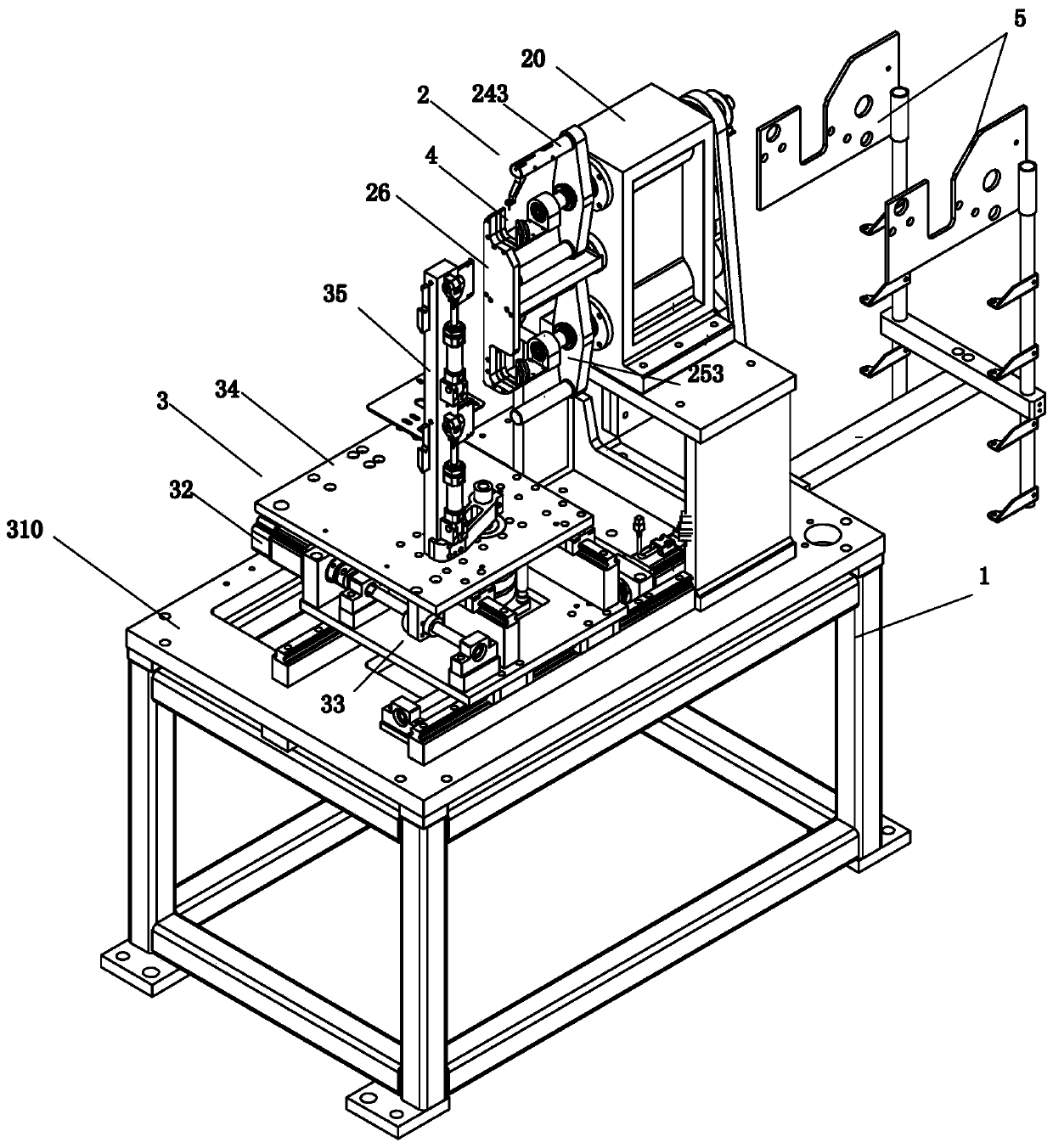

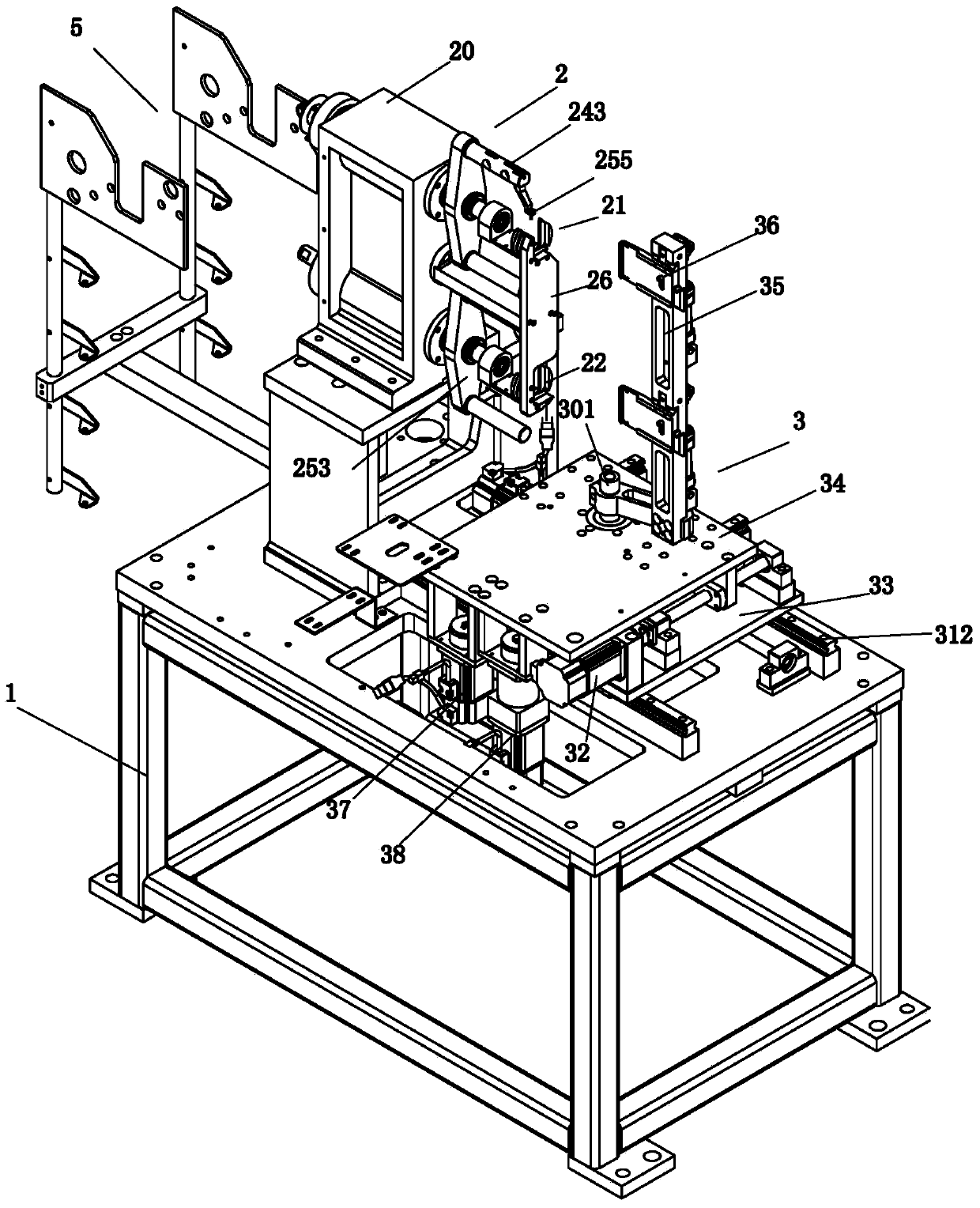

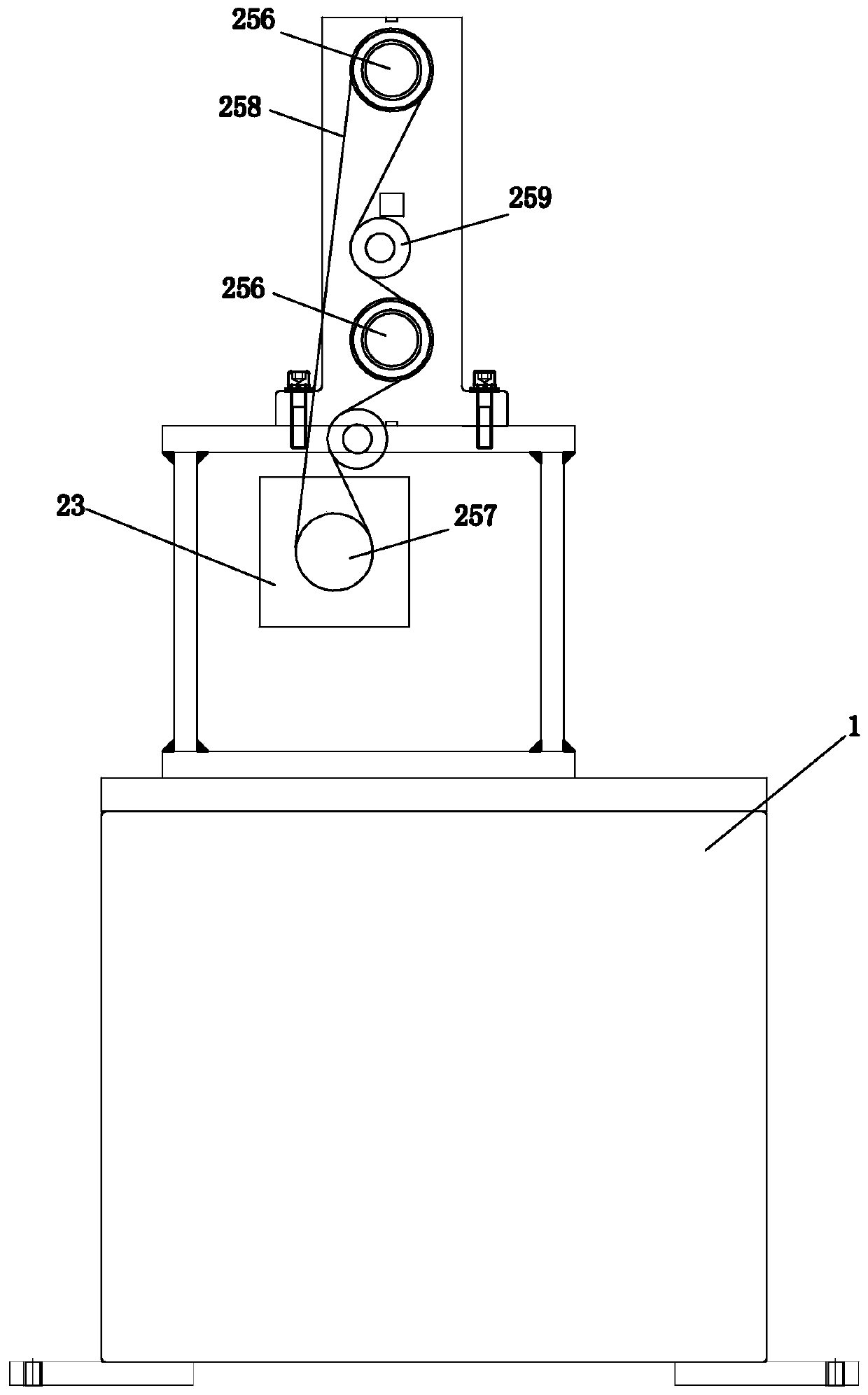

[0040] Embodiment one, see Figure 1 to Figure 16 As shown, a half-core stator needle winding machine includes a frame 1 , a wire tensioner 5 , a winding mechanism 2 , a wire baffle mechanism 4 and a stator clamp mechanism 3 .

[0041] The thread tensioner 5 is arranged on the frame 1 and is located at the rear side of the frame 1 , and is used for tensioning the thread and delivering the thread to the winding mechanism 2 .

[0042] Described winding mechanism 2 is arranged on the frame 1, and is positioned at the front side of frame 1, has upper winding station 21 and lower winding station 22, comprises upper winding rotating shaft and lower winding rotating shaft, upper, The lower winding shaft is horizontally rotated up and down and arranged on the frame 1 for winding the wires on a plurality of wire slots of the half iron core stator 5 .

[0043] The wire baffle mechanism 4 is arranged on the frame 1 and is located on the front side of the frame 1 , and is used to guide the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com