Automatic cleaning system for solar cell panel

A solar panel and automatic cleaning technology, applied in the direction of electrical components, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of low cleaning efficiency, affecting light transmittance and life, and large water consumption, so as to avoid cleaning omissions and achieve automatic effects Good, low-cost production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

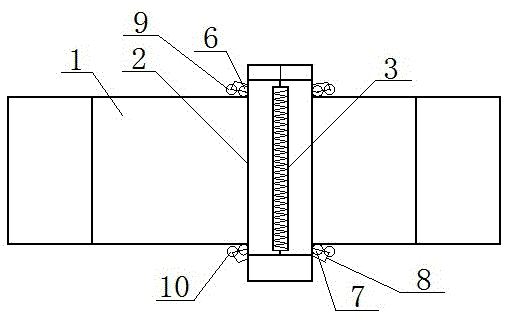

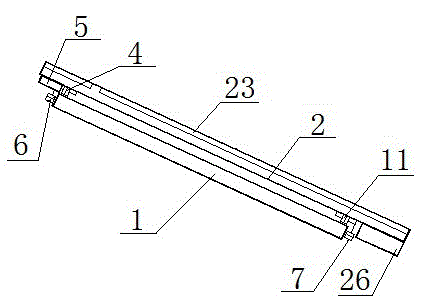

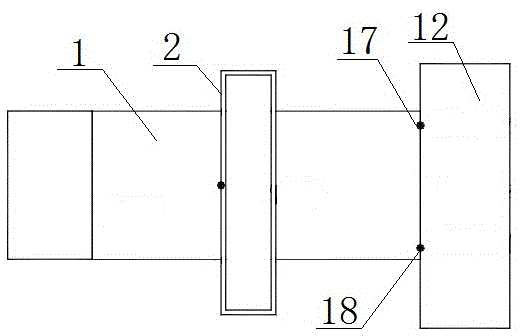

[0028] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a solar panel 1, a cleaning trolley 2 is arranged on the solar panel 1, a cleaning brush 3 is installed on the cleaning trolley 2, and the cleaning brush 3 is integrally made, and a load wheel set is installed at the bottom of the cleaning trolley 2 4. A power transmission box 5 is arranged above the bottom of the cleaning trolley 2, an active driving wheel set 6 is installed at the bottom of the power transmission box 5, a driven driving wheel set 7 is installed under the bottom of the cleaning trolley 2, the active driving wheel set 6 and the driven wheel set are installed below the bottom of the cleaning trolley 2. The drive wheel set 7 walks along the side of the solar panel 1 , and the active drive wheel set 6 , the driven drive wheel set 7 and the load wheel set 4 are respectively provided with crawler belts 8 . The two driving wheels 9 located at both ends in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com