Drum-shaped precision filter

A precision filter and drum-type technology, which is applied in the field of environmental protection water treatment equipment, can solve the problems of easy residual dirt in filter cloth, microorganisms, breeding of microorganisms in fiber filter cloth, and unguaranteed filtration accuracy, so as to achieve good washing effect and increase service life And reliability, good effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

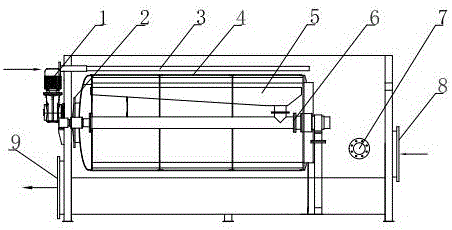

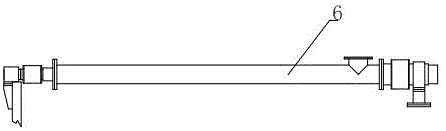

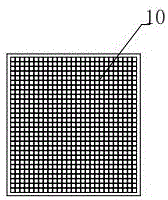

[0021] Such as Figure 1 to Figure 3 As shown, the precision filter of the present invention includes a rotary filter cartridge 4, and the filter cartridge 4 is a whole drum-shaped cylinder composed of several filter units installed separately on a drum-shaped support frame, and a single filter unit is 304 stainless steel light plate punching is used as the support module of the filter screen 10, and the filter screen 10 is made of a woven mesh made of 316 stainless steel. The filter cartridge 4 adopts the mode of central support and central transmission, and is supported on the frame by the central support shaft 6. Bearings are arranged at both ends of the central support shaft 6; the water inlet 8 is arranged on the open side of the filter cartridge 4, and the water outlet 9 is arranged on the On the other side, the sewage enters the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com