Control method of monitoring ball machine

A control method and ball camera technology, applied in image analysis, instruments, closed-circuit television systems, etc., can solve the problems of long time-consuming positioning scanning and low degree of automation, and achieve fast image capture speed, expanded field of view, and integrity assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

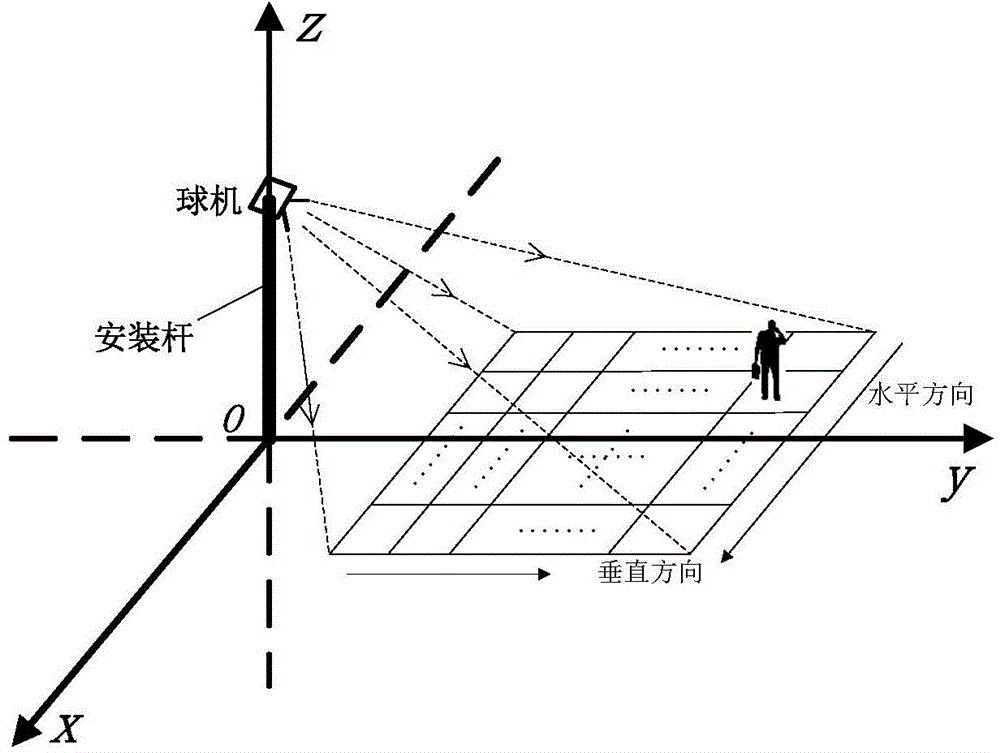

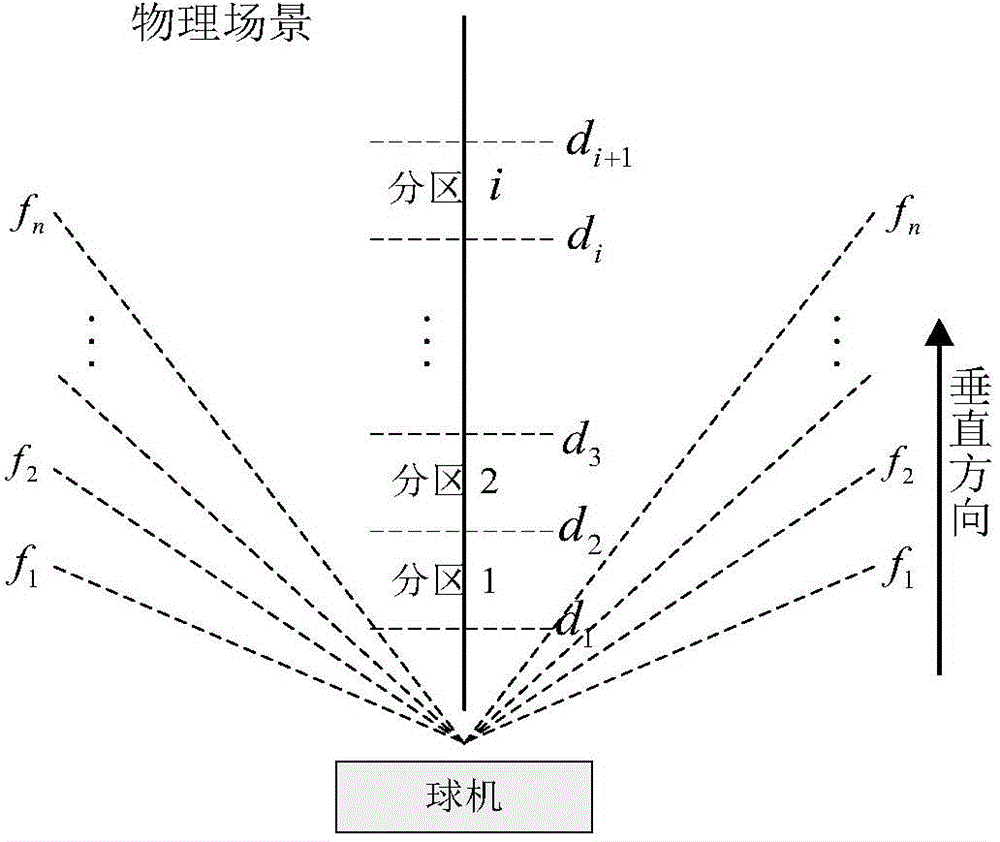

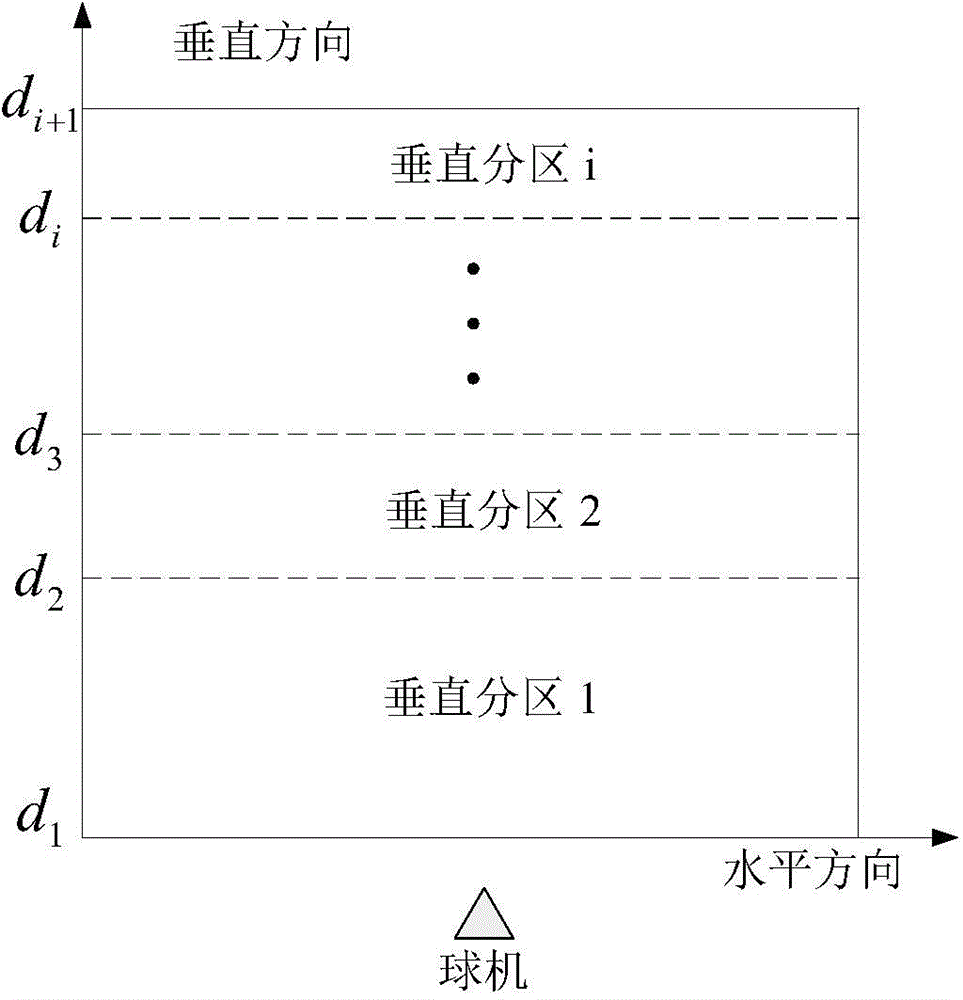

[0037] The present invention can be divided into two aspects: configuration process and real-time monitoring process. The configuration process refers to dividing the monitoring scene into horizontal and vertical partitions according to the speed dome parameters, scene information and target resolution requirements before implementing monitoring, then determining the shooting focal length of each partition and setting the preset position, and saving the dome camera orientation information and magnification information. The real-time monitoring process means that the monitoring system performs video analysis on the video frames captured by the camera during work, detects the position of the target and maps it to a specific preset position, and finally the system sends instructions to the dome camera to quickly reach the designated preset position to obtain The high-resolution image of the target, so as to achieve the purpose of identifying the details of the target.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com