All-in-one full-automatic wall surface plastering unit and use method thereof

A fully automatic, unit-based technology, applied in construction, building construction, etc., can solve problems such as single performance, uneven painting, and bulky equipment, and achieve the same density and thickness, convenient shrinkage of the nozzle, and avoid the effect of flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0036] The integrated full-automatic wall painting unit of this embodiment is mainly used for painting paints such as "putty ash" on the wall during the decoration process of the construction project. Its innovation lies in "replacing the original artificial scraping construction of putty ash on the wall by machine", so as to realize an essential reform.

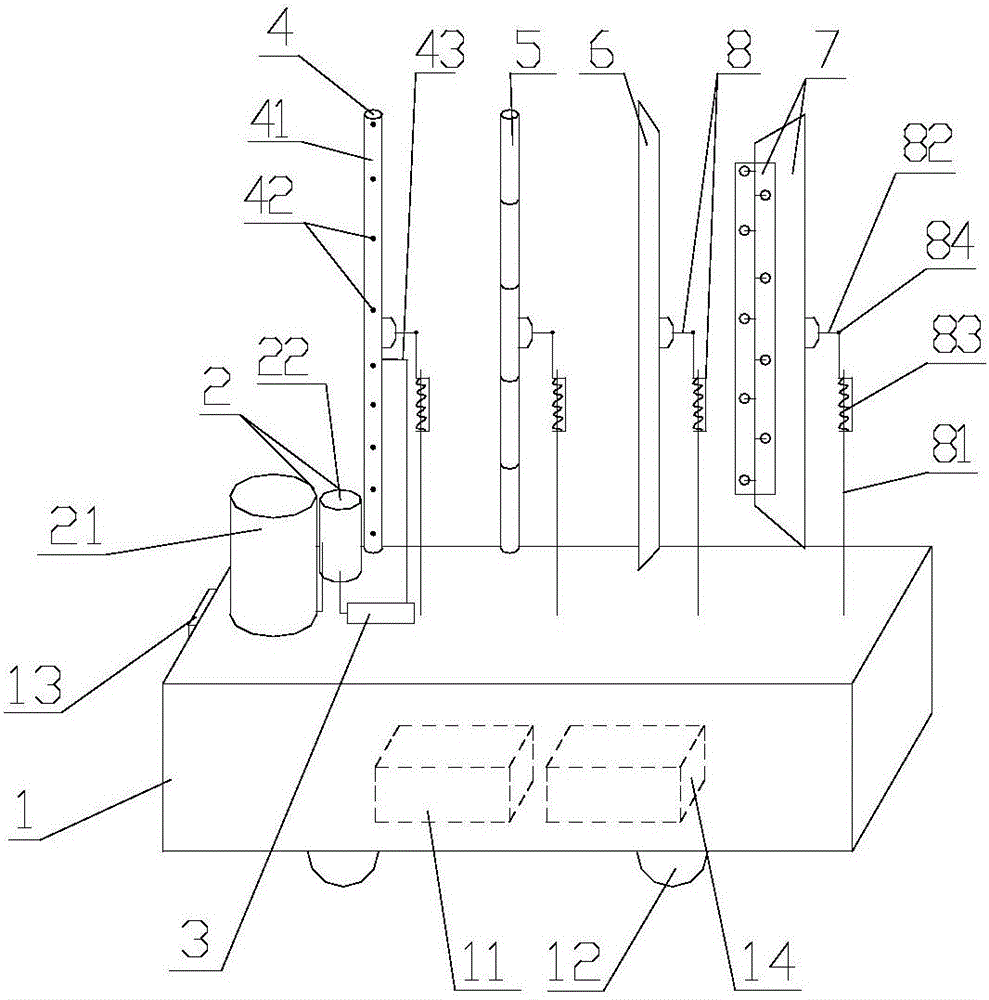

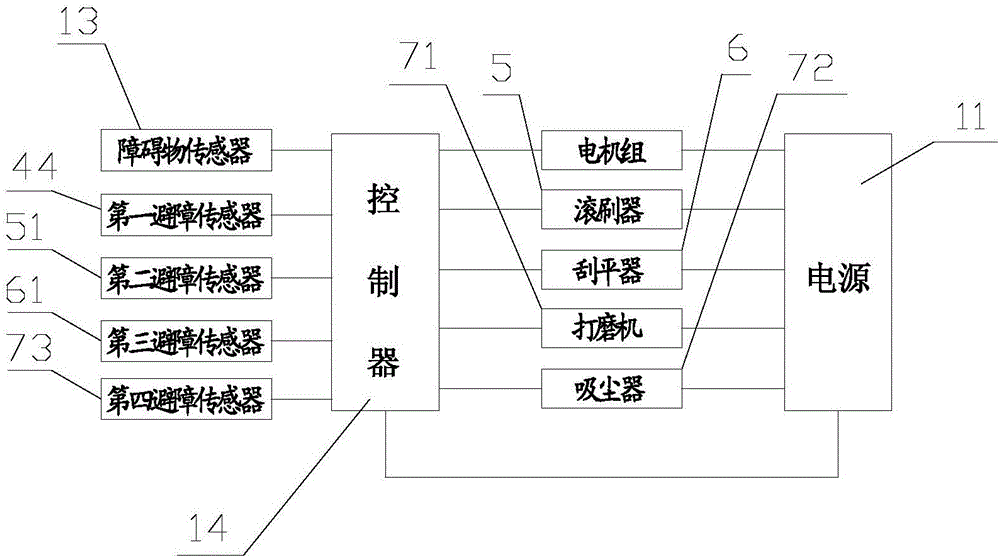

[0037] Such as figure 1 and figure 2 As shown, the integrated fully automatic wall painting unit of this embodiment includes a transport vehicle 1, four identical support structures 8 sequentially arranged on the transport vehicle, a painting mechanism arranged above the support structures, and a control system. The support structure 8 is snapped into the transport vehicle, so that it can be disassembled and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com