Annular multi-row tool magazine and tool supply method

A tool magazine and circular technology, applied in the field of tool magazine, can solve the problems of not being able to meet the quantity requirements of the tools, the tools cannot meet the processing needs, and the capacity of the tool magazine is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

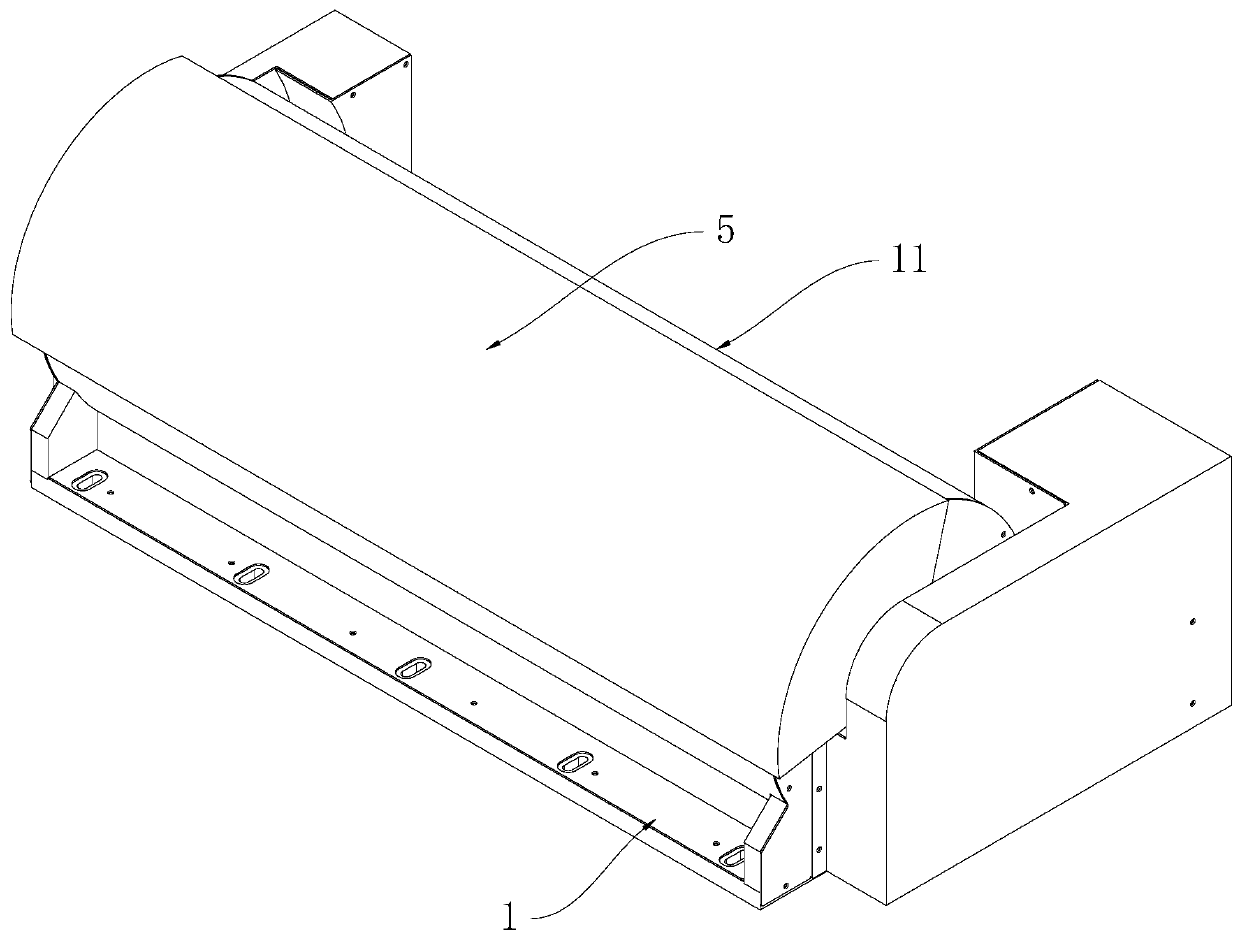

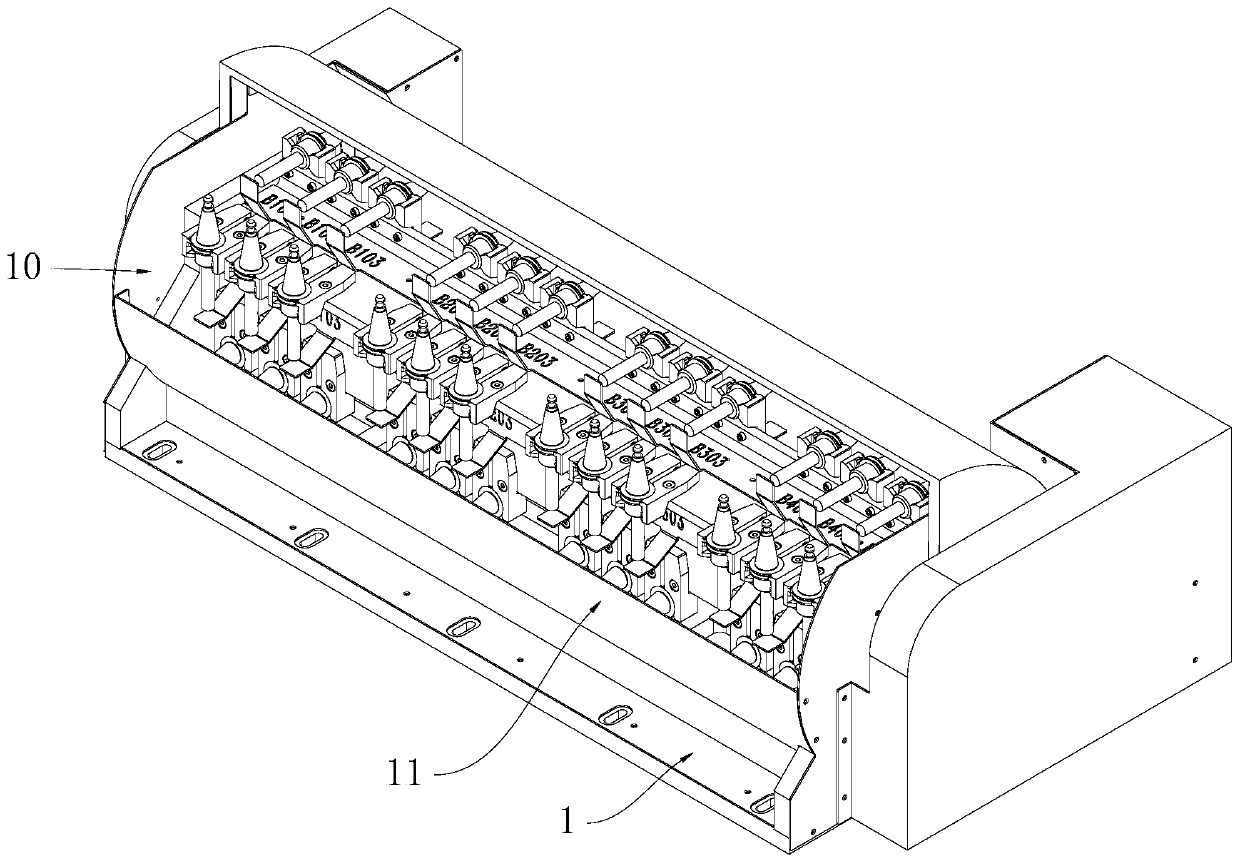

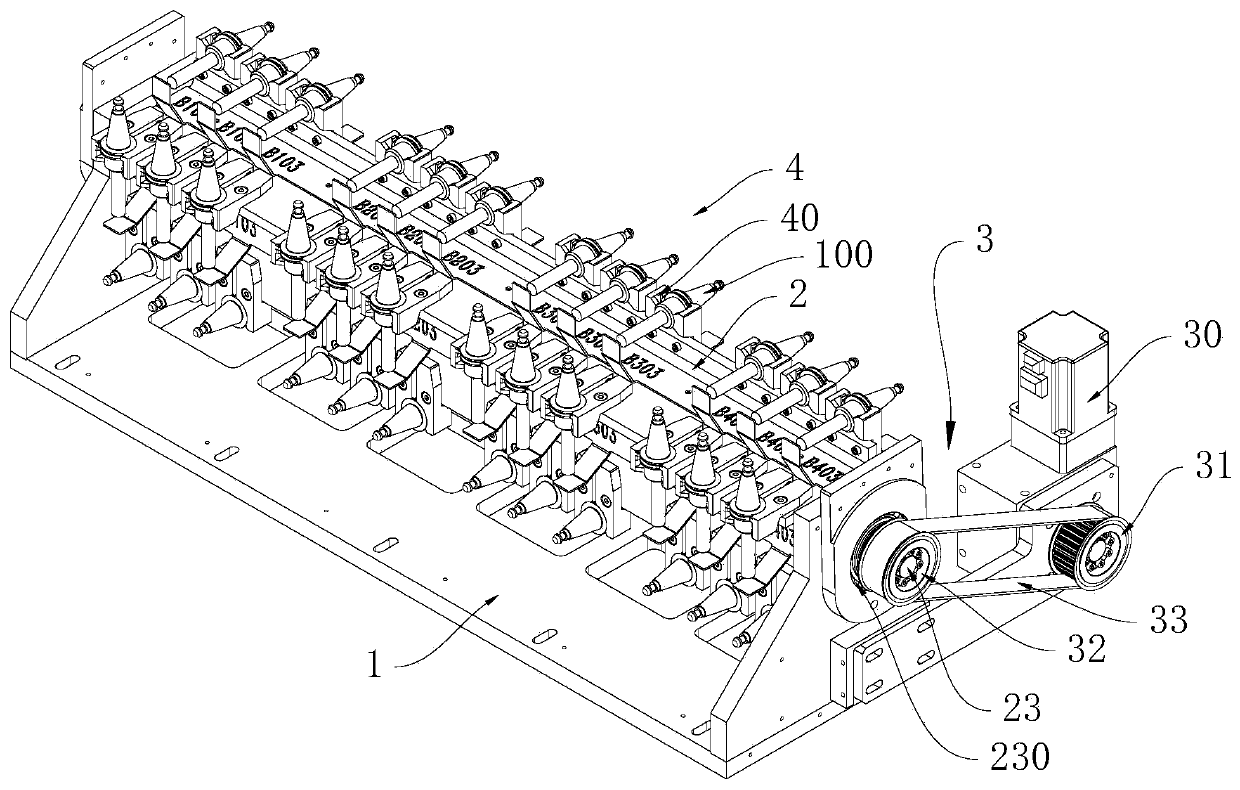

[0036] The invention discloses an annular multi-row tool magazine, which combines Figure 1 to Figure 13 As shown, it includes a support base 1, the support base 1 is provided with a rotating base 2 and a driving mechanism 3 for driving the rotating base 2 to rotate, and the rotating base 2 is provided with at least one set of clamping mechanisms 4. The clamping mechanism 4 includes a plurality of clamping jaws 40 for clamping the tool 100, and the plurality of clamping jaws 40 are evenly distributed along the circumference of the rotating base 2. When removing the tool, the driving mechanism 3 drives The rotating base 2 rotates at a preset angle, and then transports the tool 100 to a preset tool picking position.

[0037] In the above structure, the rotating base 2 is set as a mechanism that can rotate relative to the supporting base 1, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com