Full-automatic winding machine for winding plastic pipe

A plastic pipe, fully automatic technology, applied in thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of inaccurate docking, huge auxiliary unloading mechanism, and many parts, and achieve equipment use Effects of improved reliability, improved automation performance, and reduced manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

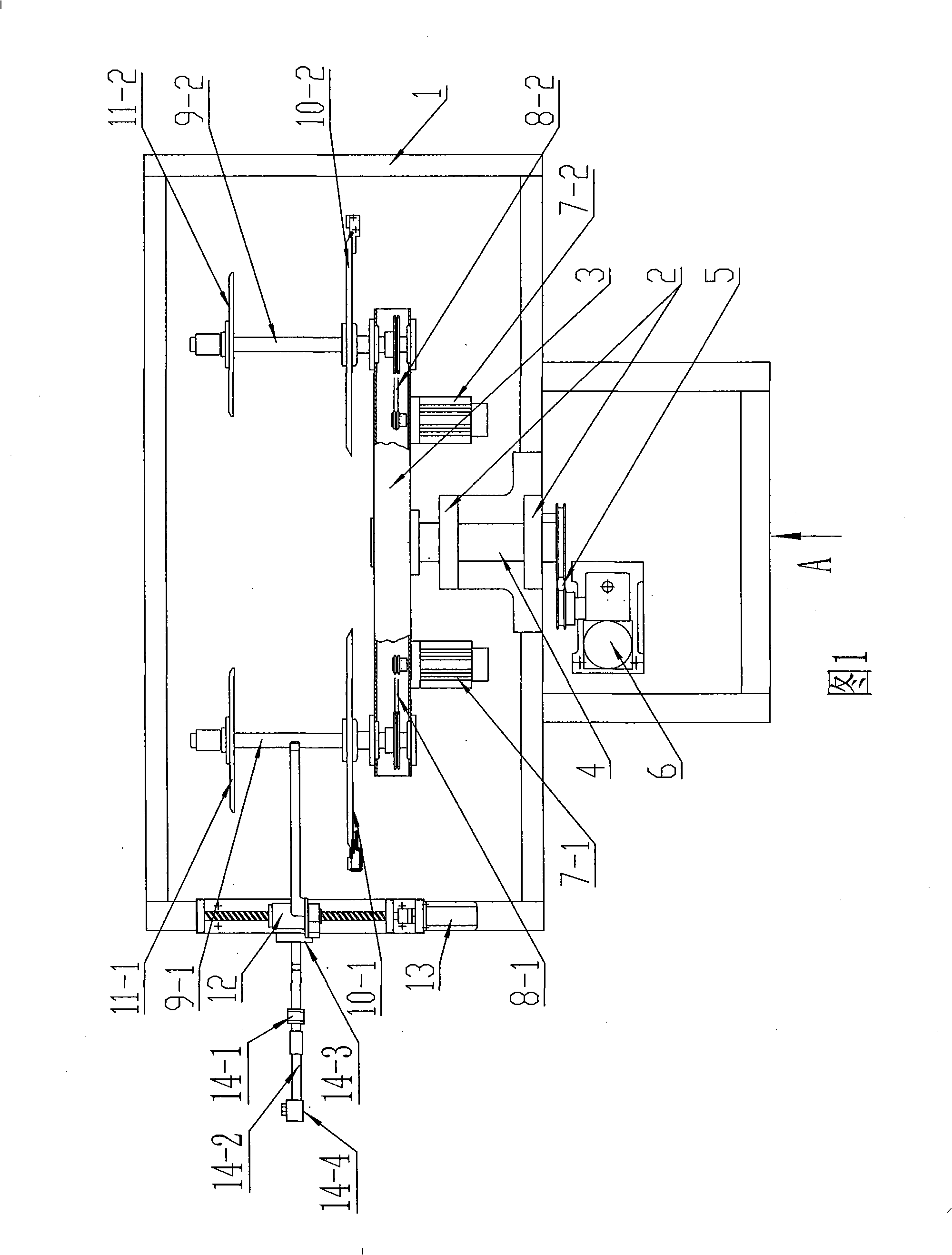

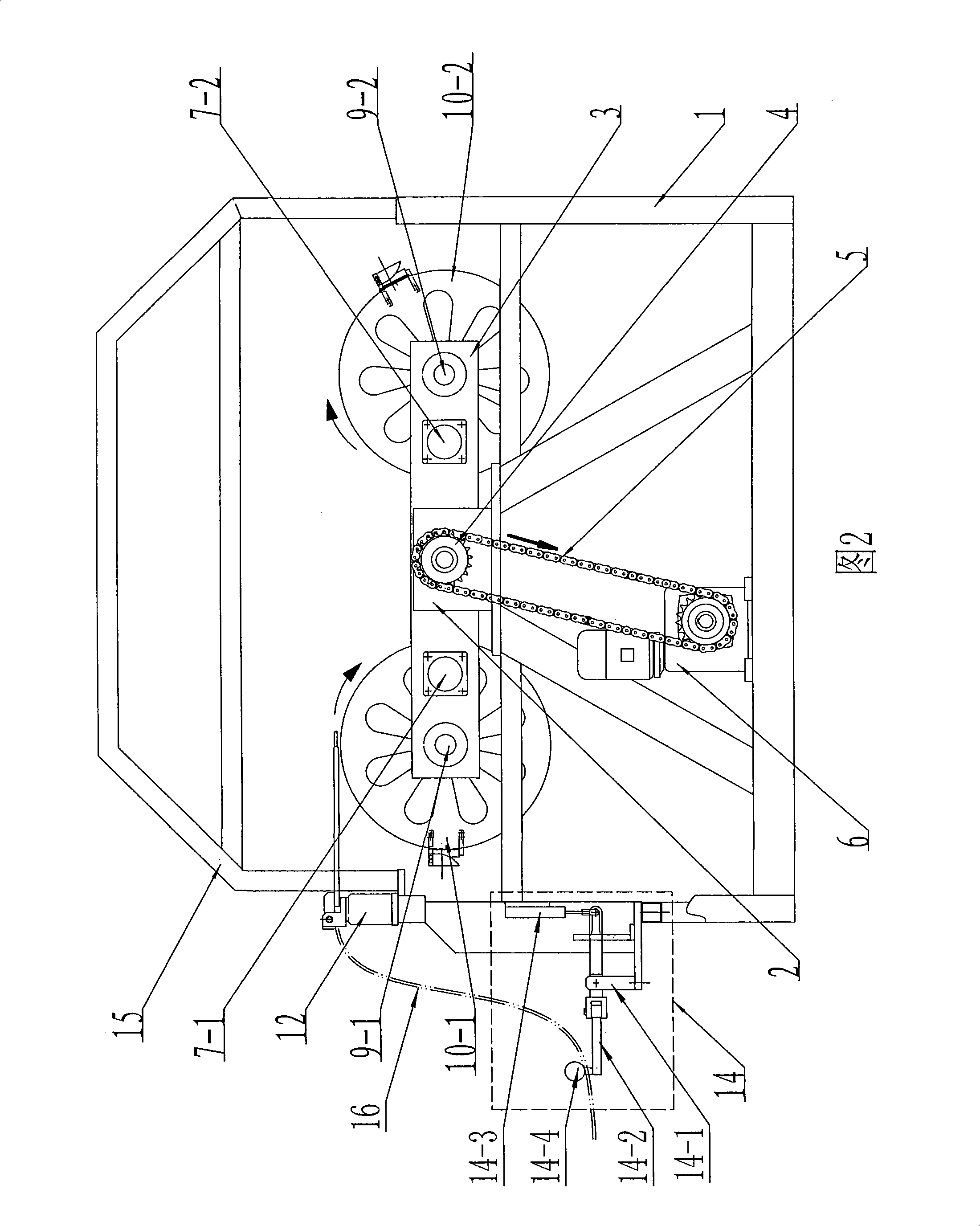

[0012] Referring to Fig. 1 and Fig. 2, the present invention comprises a main base 1, a boom rotating bracket 2, a rotating boom 3, a pipe arrangement mechanism, a tension control mechanism 14, and a protective cover 15, wherein: the boom rotating bracket 2 is installed on the main base 1, the boom rotation transmission shaft 4 is installed in the boom rotation installation bracket 2, the front end of the boom rotation transmission shaft 4 is equipped with a rotation boom 3, and the rear end is driven by a boom transmission chain 5 and a boom rotation drive motor 6 connect. Two reels 10-1, 10-2 are arranged symmetrically at both ends of the rotating arm. The main improvement of the present invention is: two reel drive motors 7-1, 7-2 are symmetrically arranged on the rotating boom 3, and the two reel drive motors are connected to each other by reel drive chains 8-1, 8-2 respectively. Two reel transmission shafts 9-1, 9-2 are connected in transmission.

[0013] Still referrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com