Adjustable Width Cassette for Wafer Film Frames

a cassette and film frame technology, applied in the field of cassettes for wafer film frame, can solve the problems of increasing storage space requirements, costly work stoppages, and multiple cassette sizes, and achieve the effects of reducing equipment set-up time, reducing storage space requirements, and reducing inventory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

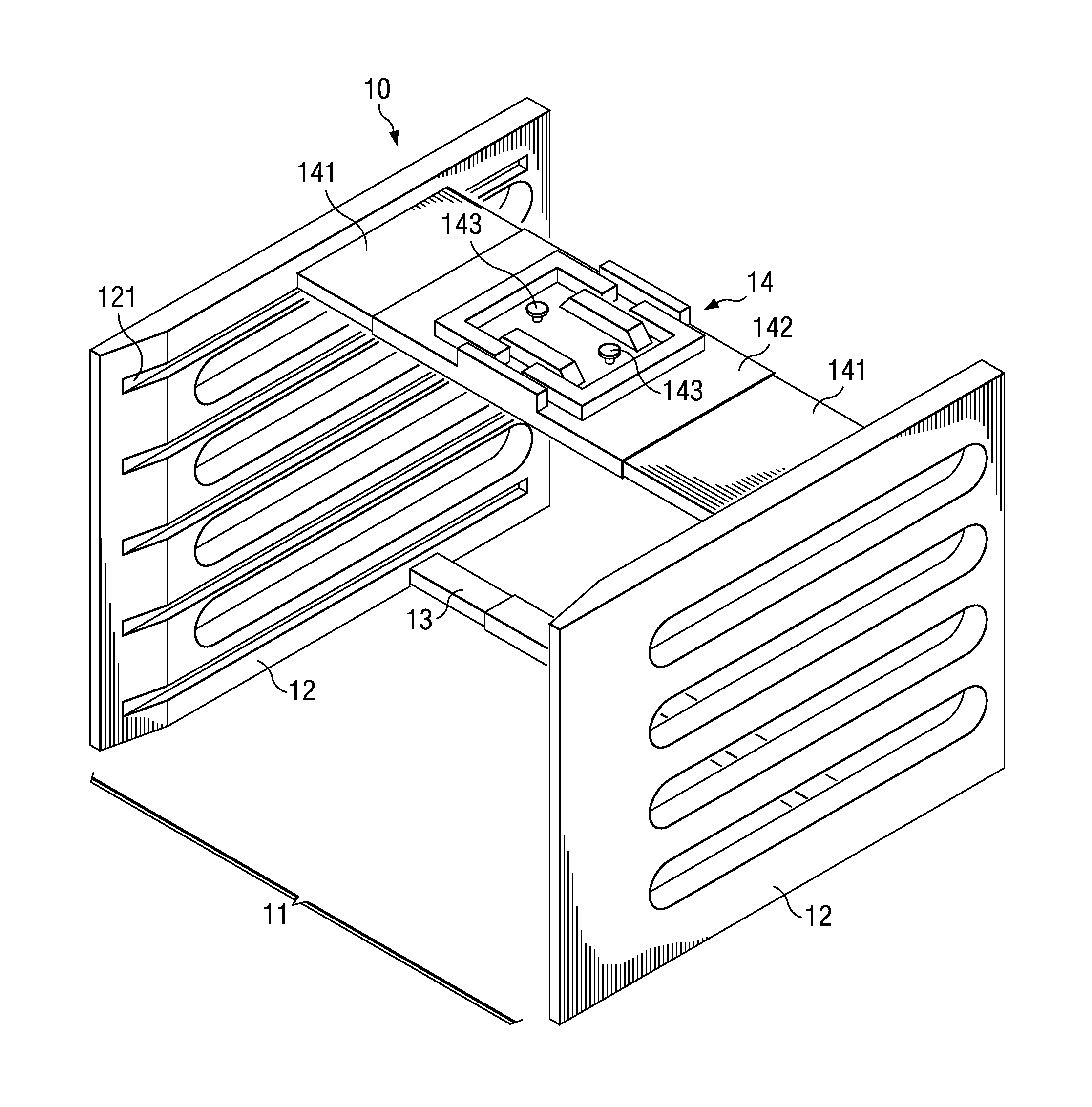

[0029]FIG. 1 provides a perspective view of the invention, an adjustable width cassette 10 for holding and transporting planar objects. The cassette 10 includes a substantially open front facing side 11 to allow insertion of thin, planar objects, a pair of vertical side panels 12 opposite and parallel to each other having a plurality of elongated opposing horizontal slots 121 on the inner surface for supporting the planar members, a sliding bar assembly 13 on the bottom side of the cassette providing connection between the side panels 12, and an adjustable length horizontal panel 14 on the top side of the cassette providing connection between the side panels 12. The horizontal structures, a sliding bar assembly 13 on the bottom and the adjustable length panel 14 on the top, are approximately centered front to back of the cassette in order to provide dimensional stability to the vertical side panels 12.

[0030]The adjustable length panel 14 on the cassette top side is an assemblage whi...

second embodiment

[0043]In a second embodiment, the adjustable width cassette is a film frame holder for storing and transporting semiconductor wafers. A film frame holder is typically used to position and secure a wafer on tape by a controlled release adhesive during the processes of sawing the wafer into individual chips, transporting the frame with sawed wafer to a pick and place equipment, and aligning the wafer in a pick and place equipment.

[0044]In FIG. 6, a top view of the adjustable width cassette 60 is shown with a film frame 67 having a semiconductor wafer 68 adhered to a support film 69. Curved sides of the frame 67 rest on slots in opposite side panels 62 of the cassette. The film frame 67 is typically fabricated with flat sides adjacent to the curves sides. Spring loaded screws 643 in the top panel 64 engage in holes at predefined locations to secure the cassette width for the selected frame and wafer width.

[0045]Diameter of the wafer 68 is a major determining factor in the film frame 67...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com