SiCf/SiC composite material flame tube and automatic preparation method thereof

A composite material, flame tube technology, applied in chemical instruments and methods, combustion methods, metal material coating processes, etc., can solve the problems of long construction period, high cost, uncontrollable quality, etc. Improved thermal shock resistance and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

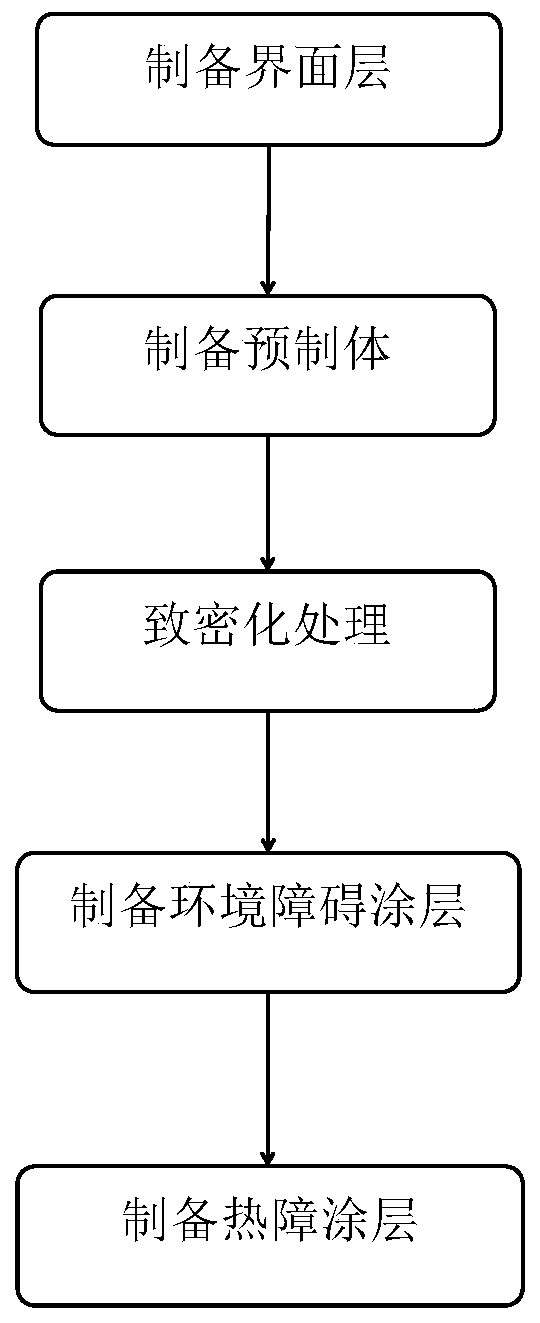

[0054] This embodiment provides a SiC f The automatic preparation method of / SiC composite material flame cylinder is characterized in that, comprises the steps:

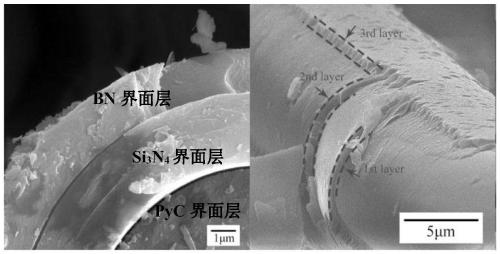

[0055] 1) Place the SiC fiber in a resistance furnace at the corresponding chemical vapor deposition temperature of the PyC interface layer, use methane as the precursor, hydrogen as the reaction gas, and argon as the dilution gas, and introduce the gas into the chemical vapor deposition furnace by bubbling method In the process, the deposition temperature is 500°C, the deposition pressure is 12KPa, the deposition time is 600min, and the thickness of the deposited interface layer is 100nm; after cooling in the furnace, SiC fibers with a continuous PyC interface layer are obtained;

[0056] 2) According to the fiber volume and fiber direction obtained by the simulation calculation, the SiC fiber with a continuous interface layer obtained in step 1) is placed in a unidirectional tape and wound into shape, including th...

Embodiment 2

[0069] This embodiment provides a SiC f The automatic preparation method of / SiC composite material flame cylinder is characterized in that, comprises the steps:

[0070] 1) Place the SiC fiber in a resistance furnace at the corresponding chemical vapor deposition temperature of the PyC interface layer, use methane as the precursor, hydrogen as the reaction gas, and argon as the dilution gas, and introduce the gas into the chemical vapor deposition furnace by bubbling method In the process, the deposition temperature is 1400°C, the deposition pressure is 0.5KPa, the deposition time is 60min, and the thickness of the deposited interface layer is 2um; after cooling in the furnace, SiC fibers with a continuous interface layer are obtained;

[0071] 2) According to the fiber volume and fiber direction obtained by the simulation calculation, the SiC fiber with a continuous interface layer obtained in step 1) is placed in a unidirectional tape and wound into shape, including the fol...

Embodiment 3

[0084] This embodiment provides a SiC f The automatic preparation method of / SiC composite material flame cylinder is characterized in that, comprises the steps:

[0085] 1) Place the SiC fiber in a resistance furnace at the corresponding chemical vapor deposition temperature of the PyC interface layer, use methane as the precursor, hydrogen as the reaction gas, and argon as the dilution gas, and introduce the gas into the chemical vapor deposition furnace by bubbling method In the process, the deposition temperature is 1000°C, the deposition pressure is 8KPa, the deposition time is 300min, and the thickness of the deposited interface layer is 1um; after cooling in the furnace, SiC fibers with a continuous interface layer are obtained;

[0086] 2) According to the fiber volume and fiber direction obtained by the simulation calculation, the SiC fiber with a continuous interface layer obtained in step 1) is placed in a unidirectional tape and wound into shape, including the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com