A bearing pad structure of a tilting pad radial bearing

A technology of radial bearing and bearing bush, applied in the field of mechanical structure, can solve the problems of bearing bush damage, uneven distribution of oil wedges in the axial direction, affecting the working stability of the bearing, etc., to achieve compact structure, improve working stability, and ensure distribution uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

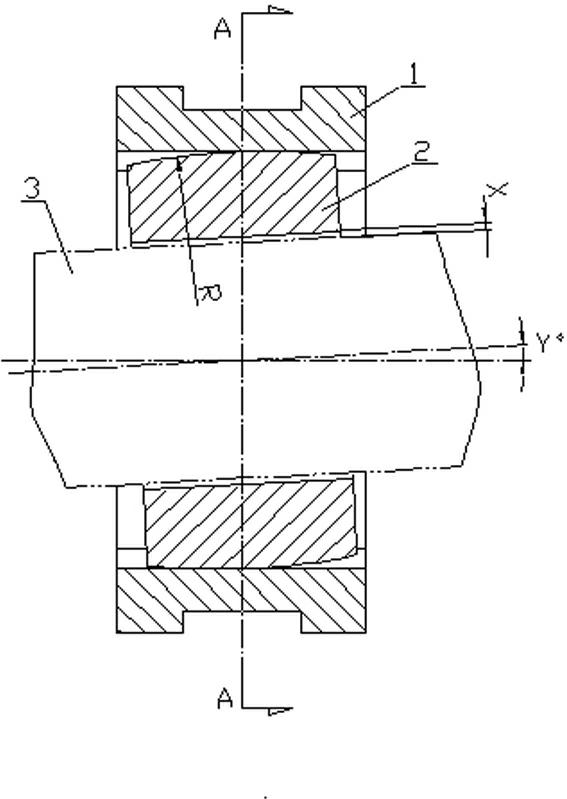

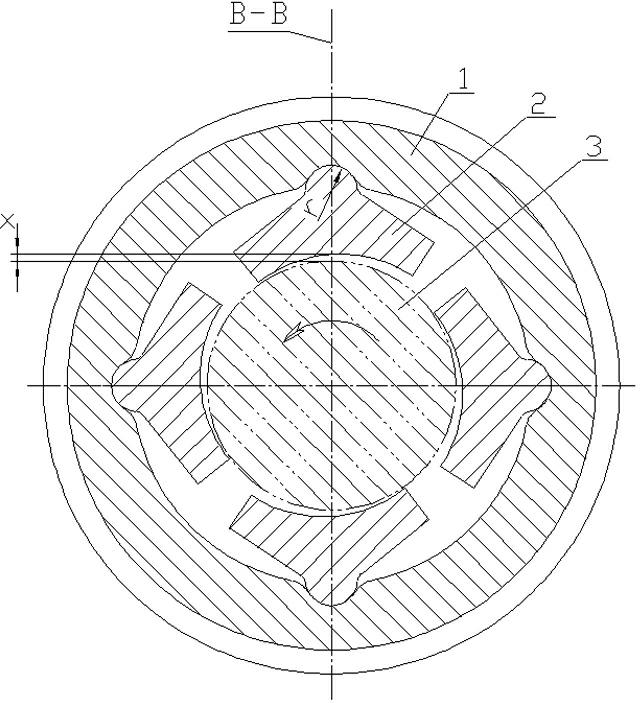

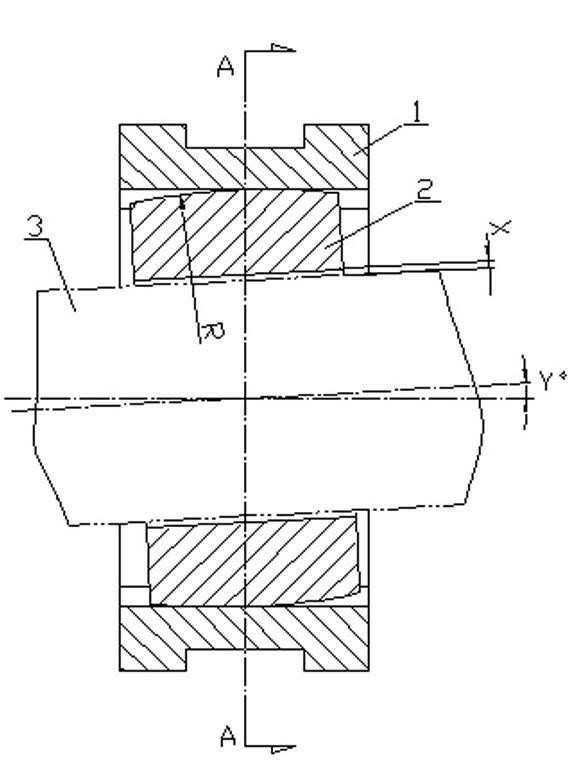

[0012] like figure 1 , figure 2 Shown: this embodiment includes parts such as bearing body 1, bearing bush 2, axle journal 3.

[0013] A bearing bush 2 is arranged between the journal 3 and the bearing body 1, and a fulcrum boss is arranged on the outside of the bearing bush 2. The boss has a small arc r on the radial plane, and the boss has a shape of The large arc shape R; the radial small arc radius r of the boss is between 3-20mm; the axial large arc radius R of the boss is not less than 800mm.

[0014] Under working conditions, the journal 3 rotates at high speed in the direction of the arrow. Under the action of pressure oil, an oil wedge is formed between the inner arc of the bearing bush 2 and the journal to bear the load. The ideal oil wedge should be uniformly distributed along the axial direction. , for example: the thickness of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com