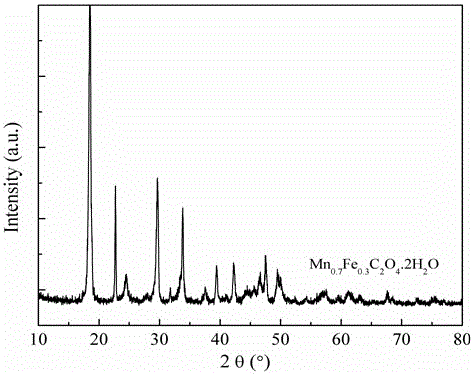

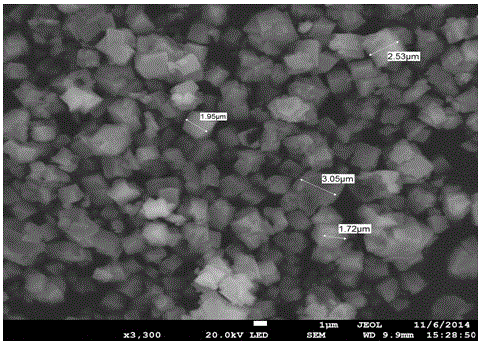

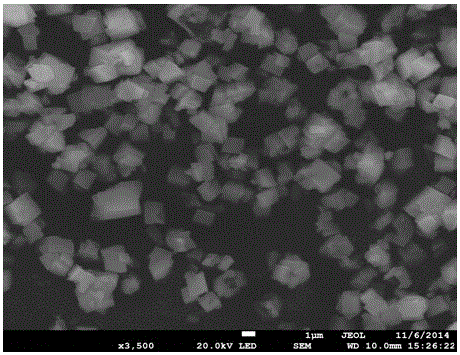

High-purity ultrafine oxalate ferromanganese and preparation method thereof

A technology of ferromanganese oxalate and ferromanganese acid, which is applied in the direction of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc. It can solve the problems of uneven particle size, large particle size of ferromanganese oxalate, and low product purity, etc. problems, to achieve the effect of narrow particle size distribution range, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of high-purity ultrafine ferromanganese oxalate comprises the steps respectively:

[0026] (1) Weigh 83.4kg of industrial grade FeSO 4 ·7H 2 O (product content ≥ 98%) in a mechanically stirred

[0027] Soluble in 1.0 m under action 3 Deionized water to get FeSO 4 Solution, adjust the pH of the solution to 4 with sulfuric acid, and add bright iron wire to prevent Fe 2+ Ion oxidation; with the Mn:Fe molar ratio of 7:3, weigh 118.3kg of industrial grade MnSO 4 ·H 2 O (product content ≥ 98%) was dissolved in the above solution, and the obtained above solution was vacuum filtered to remove impurities, weighed and quickly transferred to an ultrasonic reactor, stirred and mixed. Pass N 2 In the reactor, an inert environment is provided to prevent Fe 2+ ion oxidation.

[0028] (2) The total amount of metal ions was measured and calculated to be 996 mol, and 123.5 kg of ammonium oxalate (product content ≥ 99%) was weighed according to the molar rati...

Embodiment 2

[0033] A preparation method of high-purity ultrafine ferromanganese oxalate comprises the steps respectively:

[0034] (1) Weigh 111.2kg of industrial grade FeSO 4 ·7H 2 O (product content ≥ 98%) in mechanical stirring

[0035] Soluble in 1.0 m under the action of 3 Deionized water to get FeSO 4 Solution, adjust the pH of the solution to 4 with sulfuric acid, and add bright iron wire to prevent Fe 2+ Ion oxidation; with the Mn:Fe molar ratio of 6:4, weigh 101.4kg of industrial grade MnSO 4 ·H 2 O (product content ≥ 98%) was dissolved in the above solution, and the obtained above solution was vacuum filtered to remove impurities, weighed and quickly transferred to an ultrasonic reactor, stirred and mixed. Pass N 2 In the reactor, an inert environment is provided to prevent Fe 2+ ion oxidation.

[0036] (2) The total amount of metal ions was measured and calculated to be 996.5 mol, and 133.5 kg of sodium oxalate (product content ≥ 98.5%) was weighed according to the 1:1...

Embodiment 3

[0041] A preparation method of high-purity ultrafine ferromanganese oxalate comprises the steps respectively:

[0042] (2) Weigh 55.6 kg of industrial grade FeSO 4 ·7H 2 O (product content ≥ 98%) in mechanical stirring

[0043] Soluble in 1.0 m under the action of 3 Deionized water to get FeSO 4 Solution, adjust the pH of the solution to 4 with sulfuric acid, and add bright iron wire to prevent Fe 2+ Ion oxidation; with Mn:Fe molar ratio of 8:2, weigh 135.2kg of industrial grade MnSO 4 ·H 2 O (product content ≥ 98%) was dissolved in the above solution, and the obtained above solution was vacuum filtered to remove impurities, weighed and quickly transferred to an ultrasonic reactor, stirred and mixed. Pass N 2 In the reactor, an inert environment is provided to prevent Fe 2+ ion oxidation.

[0044] (2) The total amount of metal ions was measured and calculated to be 997.2 mol, and 183.7 kg of potassium oxalate (product content ≥ 99%) was weighed according to the molar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com