Metal-doped hollow silicon dioxide microsphere and preparation method and application thereof

A hollow silica, metal-doped technology, applied in the preparation of microspheres, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. High-level problems, to achieve the effect of maintaining uniformity, uniform particle size distribution, and ensuring the uniformity of particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Its preparation method of metal-doped hollow silica microspheres in the present embodiment comprises the following steps:

[0043](1) Prepare an inverse microemulsion system: Mix cyclohexane, Triton X-100, n-hexanol and deionized water and stir vigorously at a speed of 600rpm for 1.5h;

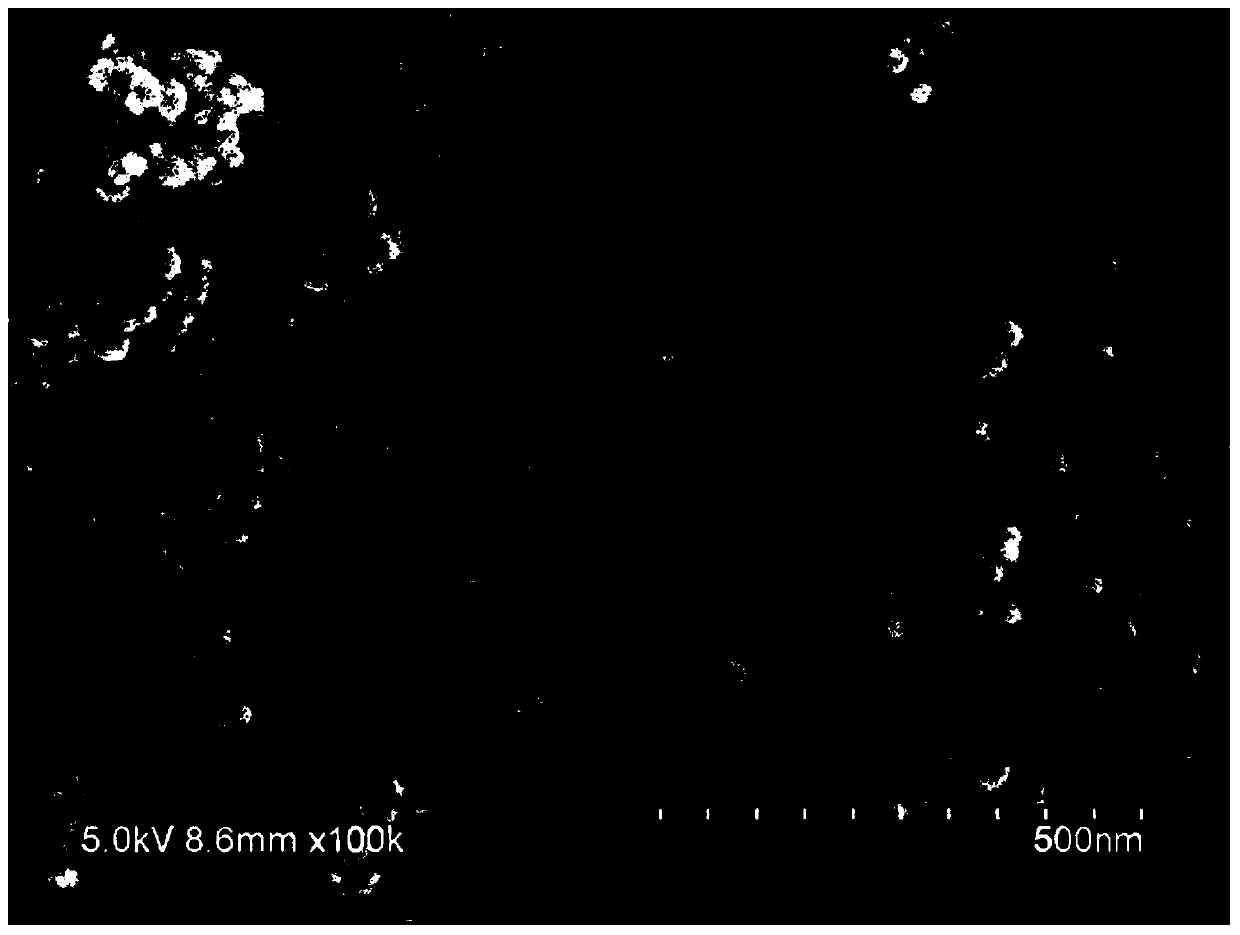

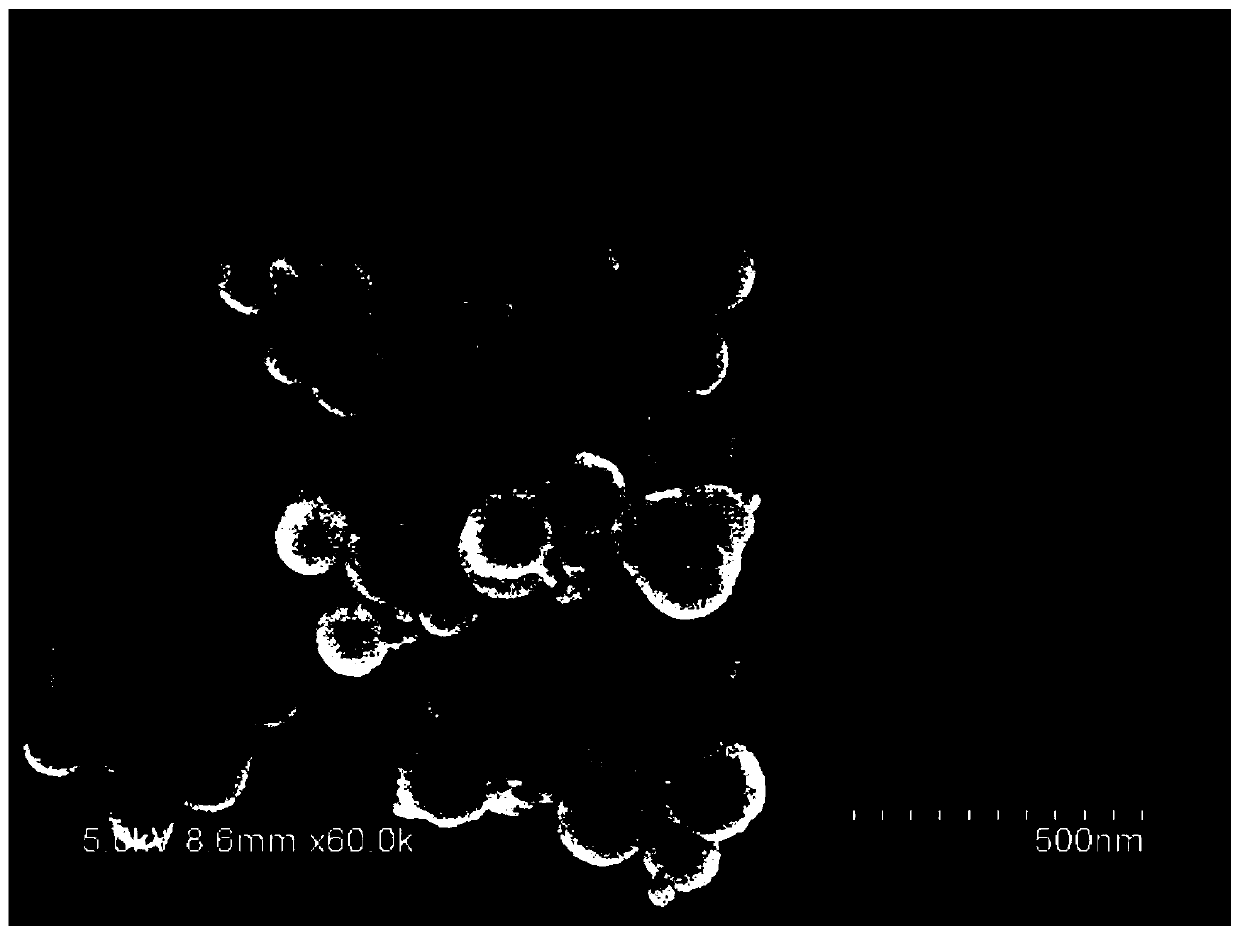

[0044] (2) Add tetraethyl orthosilicate and an ethanol solution of 3-aminopropyltrimethoxysilane (APTMS) with a concentration of 0.5 μmol / L to the inverse microemulsion system, and then vigorously stir at a speed of 600 rpm for 3 h; Add concentrated ammonia water (mass concentration is 28%) subsequently and react 10h with the rotating speed of 150rpm, obtain such as figure 1 Undoped silica microspheres with uniform particle size distribution shown;

[0045] Ensure that the volume ratio of cyclohexane, Triton X-100, n-hexanol, deionized water, tetraethylorthosilicate, 3-aminopropyltrimethoxysilane (APTMS) in ethanol and concentrated ammonia water is 125:30: 5:5:1:0.25:2.5.

[0046] (3...

Embodiment 2

[0057] Its preparation method of metal-doped hollow silica microspheres in the present embodiment comprises the following steps:

[0058] (1) Prepare an inverse microemulsion system: Mix cyclohexane, Triton X-100, n-hexanol and deionized water and stir vigorously at a speed of 700rpm for 3h;

[0059] (2) Add tetraethyl orthosilicate and an ethanol solution of 3-aminopropyltrimethoxysilane (APTMS) with a concentration of 0.6 μmol / L to the inverse microemulsion system, and then vigorously stir at a speed of 700 rpm for 5 h; Then add concentrated ammonia water (mass concentration: 29%) and stir at a speed of 200 rpm for 15 hours to obtain undoped silica microspheres with uniform particle size distribution;

[0060] Ensure that the volume ratio of cyclohexane, Triton X-100, n-hexanol, deionized water, tetraethylorthosilicate, 3-aminopropyltrimethoxysilane (APTMS) in ethanol and concentrated ammonia water is 125:30: 5:15:5:0.25:2.5.

[0061] (3) Centrifuge after mixing undoped si...

Embodiment 3

[0072] Its preparation method of metal-doped hollow silica microspheres in the present embodiment comprises the following steps:

[0073] (1) Prepare an inverse microemulsion system: Mix cyclohexane, Triton X-100, n-hexanol and deionized water and stir vigorously at a speed of 800 rpm for 3 hours;

[0074] (2) Add tetraethyl orthosilicate and the ethanol solution of 3-aminopropyltrimethoxysilane (APTMS) with a concentration of 1 μmol / L to the inverse microemulsion system, then vigorously stir at a speed of 800 rpm for 5 h; then Add concentrated ammonia water (mass concentration: 30%) and stir at a speed of 250 rpm for 15 hours to obtain undoped silica microspheres with uniform particle size distribution;

[0075] Ensure that the volume ratio of cyclohexane, Triton X-100, n-hexanol, deionized water, tetraethylorthosilicate, 3-aminopropyltrimethoxysilane (APTMS) in ethanol and concentrated ammonia water is 125:30: 5:15:5:0.25:2.5.

[0076] (3) Centrifuge after mixing undoped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com