Metal atomization pulverizing equipment with low satellite sphere content

A technology of atomized powder making and metal, which is applied in the field of metal atomized powder making equipment, can solve the problems of reducing the powder making rate of metal atomized powder, and achieve the effect of avoiding deformation and improving heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

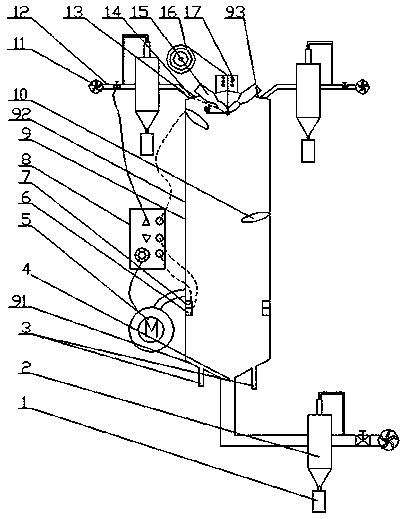

[0026] refer to figure 1 : the metal atomization pulverizing equipment that a kind of satellite ball content of present embodiment is low comprises metal feeding mechanism 17, atomizing device 15, atomizing tower 9 and powder separating device; Described metal feeding mechanism 17 and atomizing device 15 connected, the atomizing device 15 is installed on the top of the atomizing tower 9, the bottom of the atomizing tower 9 is provided with a main powder outlet 4, and the main powder outlet 4 communicates with the powder separation device; the side wall of the atomizing tower 9 There are four powder outlet holes 14 on the upper end or the sealing head 93. The powder outlet holes 14 are located at the periphery of the atomized powder outlet coke sink area at the bottom of the atomization device 15. The powder outlet holes 14 pass through the powder outlet pipeline 13 and the powder outlet. Separator connection.

[0027] The powder outlet holes 14 are uniformly distributed on th...

Embodiment 2

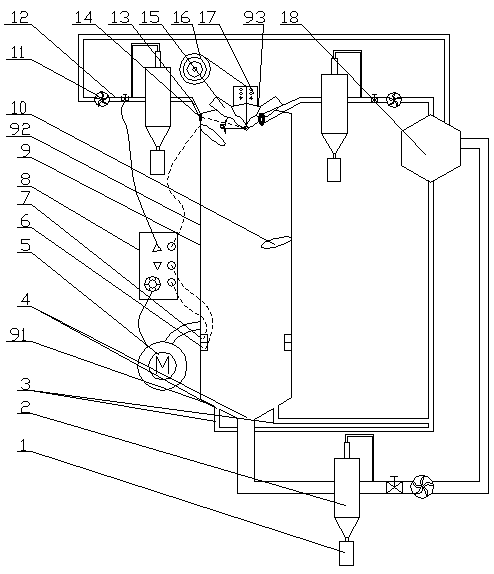

[0033] refer to figure 2 : the metal atomization pulverizing equipment that a kind of satellite ball content of present embodiment is low, compares with embodiment 1, there is following difference:

[0034] The number of the powder outlet holes 14 is three.

[0035] The line connecting the center of the powder outlet hole 14 and the center point of the powder outlet focal sink area at the bottom outlet of the atomizer 15 is inclined upwards, forming an angle of 8° with the horizontal direction.

[0036] The height-to-diameter ratio of the cylindrical tower body 92 is 3:1.

[0037] The metal atomization powder making equipment also includes a gas purification and recycling device 18, the gas inlet end of the gas purification and recycling device 18 is connected with the exhaust pipe of the powder separation device, and its gas outlet is connected with the atomization tower 9. The intake pipe 3 communicates.

[0038] When the height-to-diameter ratio of the cylindrical tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com