Liquid forging Al-Cu-Zn aluminum alloy and preparation method thereof

An al-cu-zn, liquid die forging technology, applied in the field of liquid die forging Al-Cu-Zn aluminum alloy and its preparation, can solve the problems of unqualified tensile strength, poor metallurgical quality of hubs, wide crystallization range, etc. Achieve outstanding performance, excellent formability, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

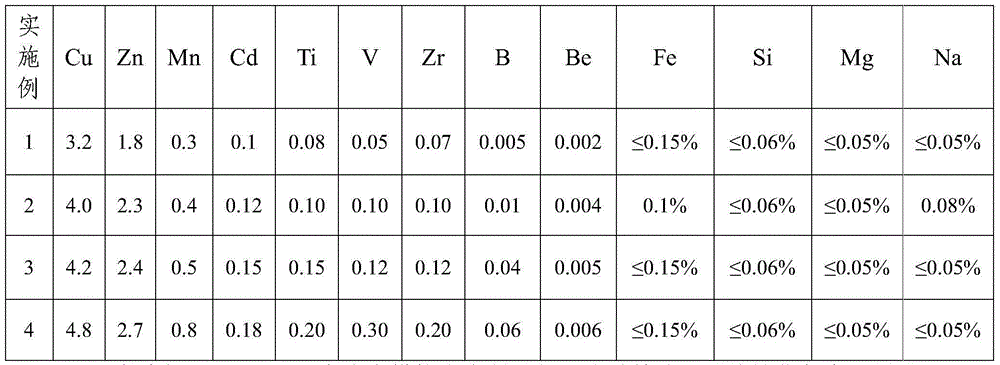

[0030] Table 1 below shows the chemical composition and weight percentage of the novel medium-strength and high-toughness aluminum alloy proposed by the present invention.

[0031] Table 1 Chemical composition and weight percentage of new Al-Cu-Zn series medium-high-strength and tough aluminum alloys

[0032]

[0033] Table 2 shows the properties of the liquid forged alloy products in Examples 1, 2, 3, and 4 after solution aging treatment.

[0034] Table 2 Aging properties of alloy products in Examples 1, 2, 3, and 4

[0035] Example Tensile strength Rm / MPa Yield strength Rp 0.2 / MPa Elongation A / % 1 400 327 10 2 420 334 10.9 3 460 354 14 4 440 359 11.2

[0036] As can be seen from Table 1, among them embodiment 1, 3, 4 meet the requirement of individual content of other impurity elements ≤ 0.05%, impurity total content ≤ 0.3%, embodiment 2 does not meet the requirement, wherein the alloy in embodiment 2 is chemically After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com