Preparation method for super-hydrophilic carbon nanotube nano-porous membrane

A carbon nanotube and nanoporous technology, which is applied in the field of preparation of superhydrophilic carbon nanotube nanoporous films, can solve the problems of nanomaterial agglomeration and poor interfacial compatibility, complex synthesis process, limited application and the like, and achieves improved distribution, The process is simple and the effect of avoiding the generation of structural defects in the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

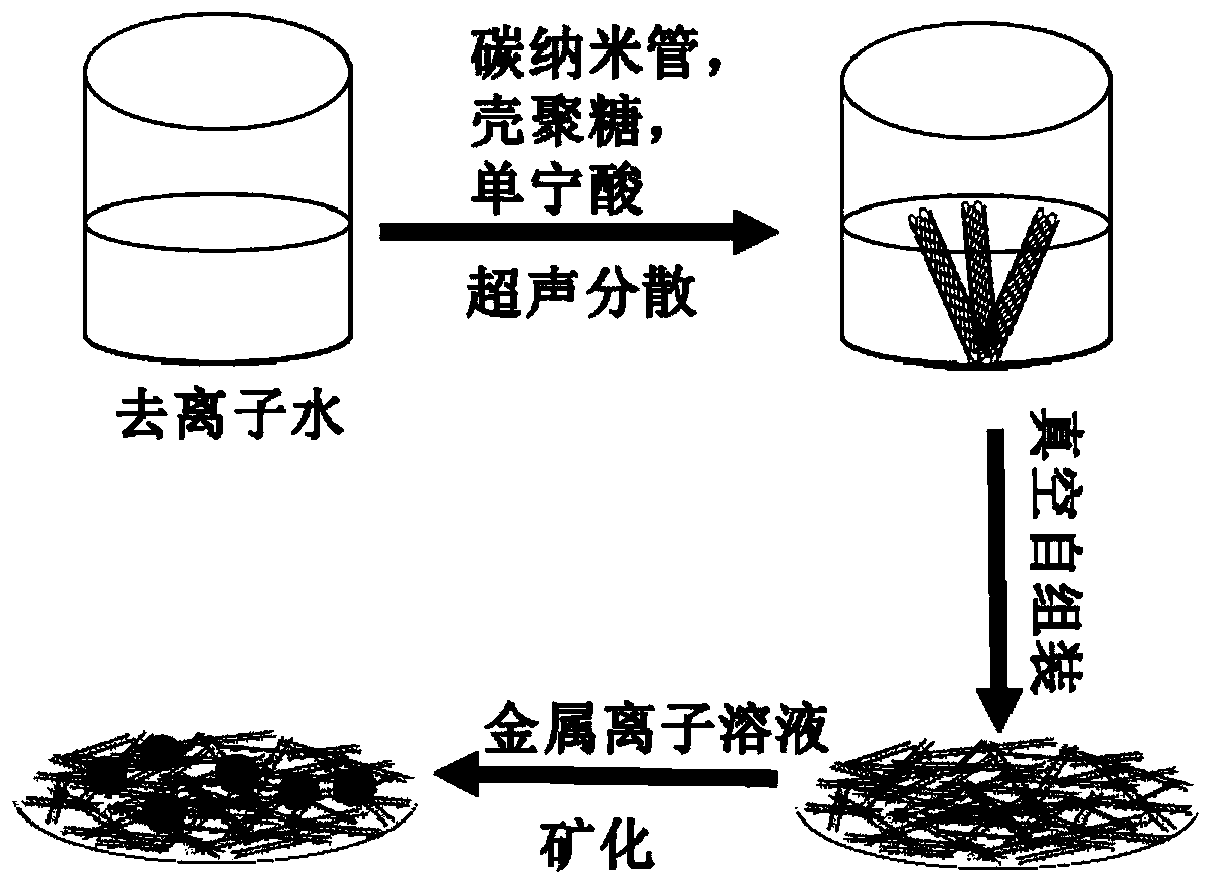

[0033] In this embodiment, a method for preparing a superhydrophilic carbon nanotube nanoporous membrane comprises the following steps:

[0034] (1) Taking carbon nanotubes, tannic acid, and chitosan as raw materials, adding the raw materials and water into a beaker, adjusting the pH of the dispersion to 3, and ultrasonically dispersing for 30 minutes to obtain a carbon nanotube dispersion; Carbon nanotubes are carboxylated carbon nanotubes, and the concentration of the carbon nanotubes in the dispersion is 0.1 mg / mL; the mass ratio of the tannic acid to chitosan is 1:1; the carbon nanotubes and tannin The acid mass ratio is 1:4;

[0035] (2) After standing the carbon nanotube dispersion obtained in step (1) for 12 hours, centrifuge at a speed of 8000r / min for 20 minutes, take the supernatant, and then dilute it 25 times;

[0036] (3) The carbon nanotube dispersion liquid after the step (2) gained dilution is filtered on the microfiltration bottom membrane under the vacuum co...

Embodiment 2

[0041] In the present embodiment, the processing steps of a preparation method of a superhydrophilic carbon nanotube nanoporous membrane are the same as in Example 1, the difference is only that the mass ratio of carbon nanotubes and tannic acid described in step (1) is 1:16, in step (4), immerse the carbon nanotube film in a titanium lactate solution with a volume of 20mL and a concentration of 15mg / mL, and soak at 20°C for 2h.

[0042] CNT@CS / TA-TiO prepared by the above examples 2 The surface of the nanoporous membrane is a porous structure, and the titanium dioxide nanoparticles are evenly distributed on the surface of the membrane; the hydrophilicity of the membrane is expressed by the data of the water contact angle on the surface of the membrane and the infiltration time. For the data, see Figure 7 , Figure 8 , the initial water contact angle value on the film surface is 65.7°, and the water droplet is completely infiltrated within 10s, showing that CNT@CS / TA-TiO 2 ...

Embodiment 3

[0044] In this embodiment, the process steps of a preparation method of a superhydrophilic carbon nanotube nanoporous membrane are the same as in Example 1, except that the carbon nanotube membrane is soaked in a volume of 30mL, 1wt % ZrOCl 2 .8H 2 Soak in a mixed solution of O and 0.1mol / L hydrochloric acid for 6 hours at 80°C.

[0045] CNT@CS / TA-ZrO prepared by the above examples 2 The surface of the nanoporous membrane is a porous structure, and the zirconia nanoparticles are evenly distributed on the surface of the membrane; the hydrophilicity of the membrane is expressed by the water contact angle data on the surface of the membrane and the infiltration time. For the data, see Figure 7 , Figure 8 , the initial water contact angle value on the film surface is 16.1°, and the water droplet is completely infiltrated within 1s, showing that CNT@CS / TA-ZrO 2 Nanoporous membranes exhibit superhydrophilic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com