Monocrystalline nickel-cobalt-lithium manganate cathode material and preparation method and applications thereof

A technology of nickel-cobalt-lithium-manganese-manganate and positive-electrode materials, which is applied in the field of single-crystal nickel-cobalt-lithium-manganese-manganese positive-electrode materials and its preparation, can solve problems such as increased processing difficulty, increased side reactions, and easy breakage, so as to improve safety performance and Cycle stability, increase cycle stability, and avoid structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

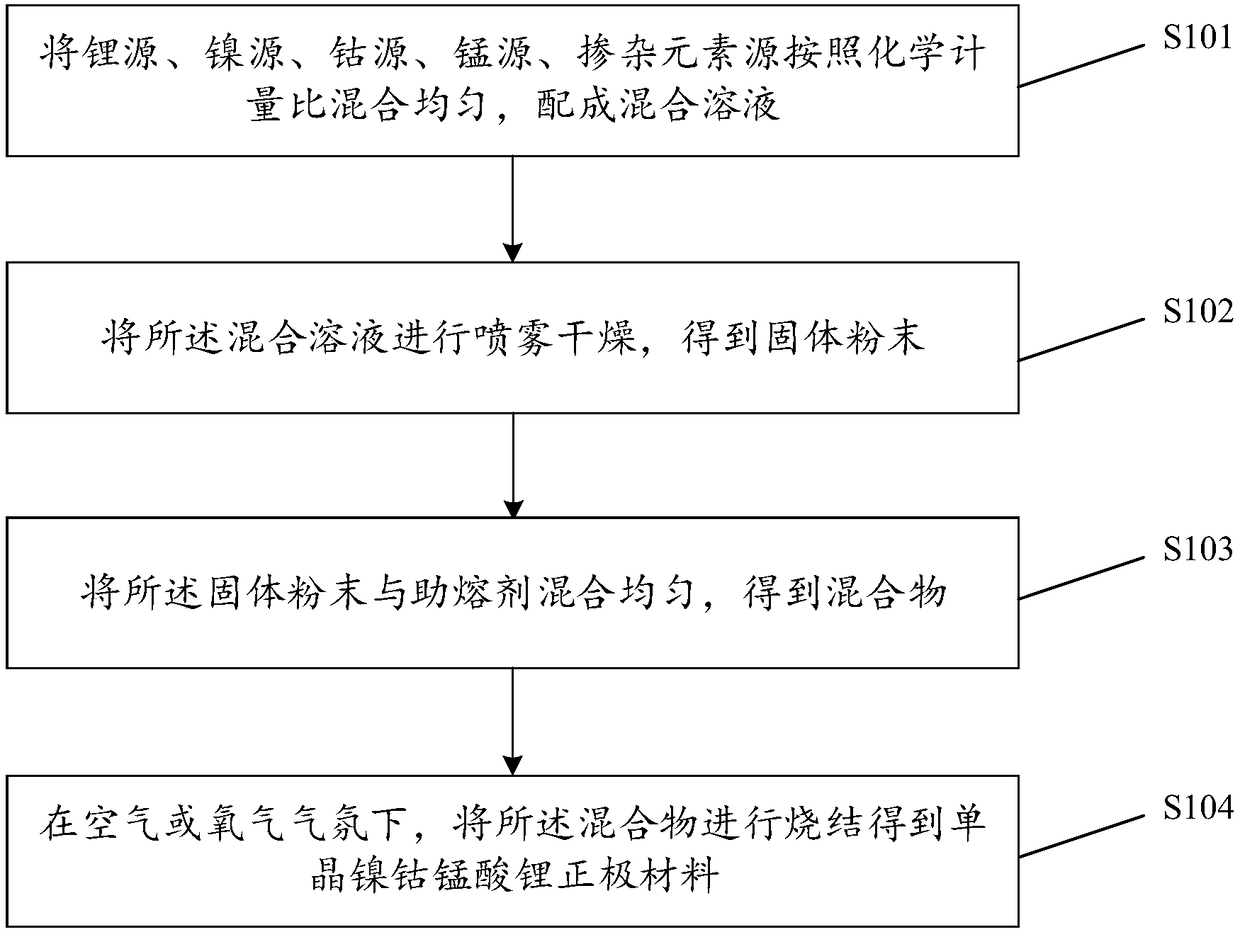

[0033] see figure 1 , a method for preparing a single crystal nickel cobalt lithium manganese oxide positive electrode material provided for the implementation of the present invention, comprising:

[0034] Step S101: Mix the lithium source, the nickel source, the cobalt source, the manganese source, and the doping element source uniformly according to the stoichiometric ratio to form a mixed solution.

[0035] In an embodiment of the present invention, the lithium source includes one or more combinations of lithium carbonate, lithium hydroxide, lithium acetate, lithium nitrate, and lithium sulfate, and the nickel source includes nickel sulfate, nickel nitrate, and nickel acetate. , the combination of one or more in nickel chloride, described cobalt source comprises the combination of one or more in cobalt sulfate, cobalt nitrate, cobalt acetate, cobalt chloride, and described manganese source comprises manganese sulfate, nitric acid A combination of one or more of manganese,...

Embodiment 1

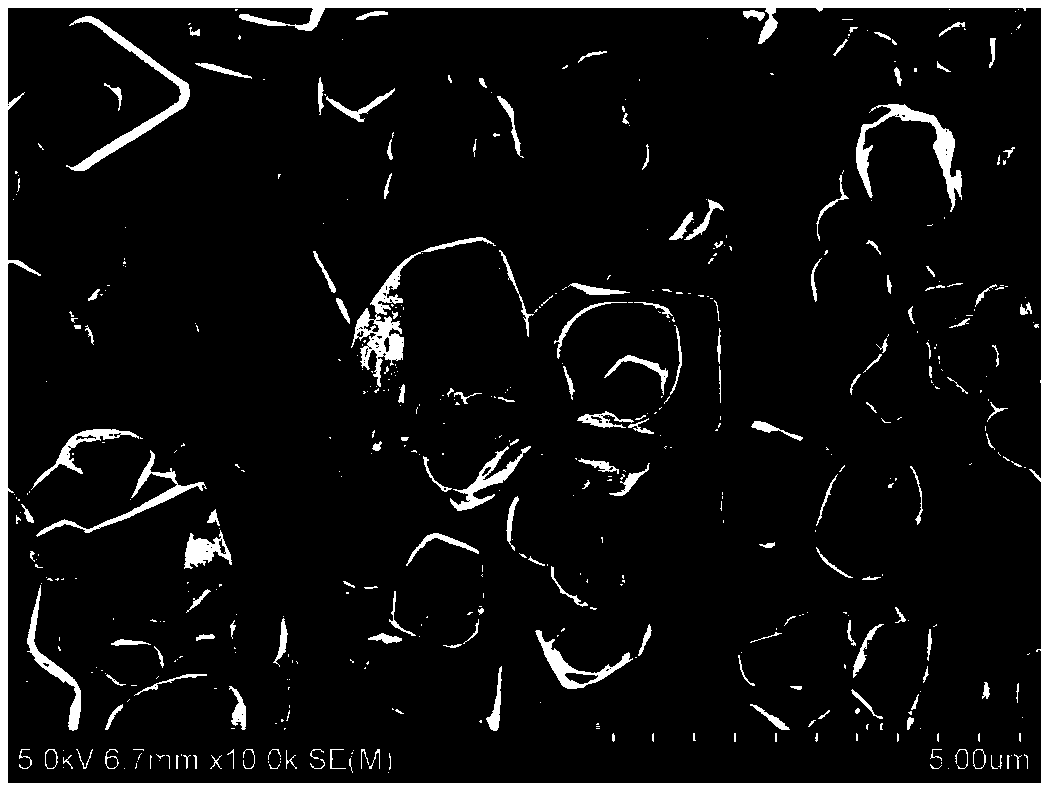

[0058]Lithium nitrate, nickel nitrate, cobalt nitrate, and manganese nitrate are formulated into a solution, and the molar ratio is 1.08:0.5:0.2:0.3, and they are mixed evenly, and the raw materials are fully mixed by spray drying at 200°C to obtain a solid powder, and then The solid powder is mixed with the flux NaCl by ball milling to obtain a mixture, wherein the mass proportion of the flux NaCl in the mixture is 5%. Under the air atmosphere, heat the mixture at 500°C / h to 600°C for 4h, continue to heat up at 500°C / h to 850°C for 10h, cool to room temperature, wash and dry, and pass through a 400-mesh sieve to obtain single crystal nickel Lithium cobalt manganese oxide cathode material, its chemical formula is LiNi 0.5 co 0.2 mn 0.3 o 2 . The prepared single crystal nickel cobalt lithium manganese oxide positive electrode material was subjected to scanning electron microscopy, and the results were as follows figure 2 As shown, it shows that the prepared single crystal...

Embodiment 2

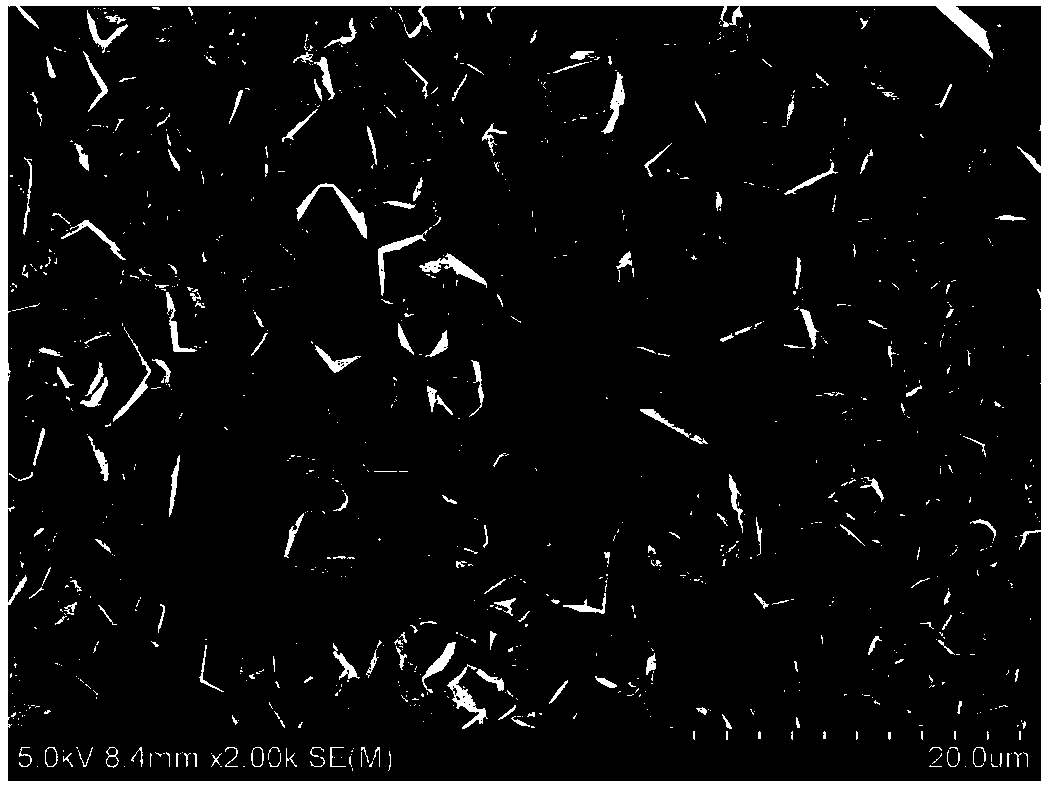

[0060] Lithium acetate, nickel acetate, cobalt acetate, and manganese acetate are made into a solution, and the molar ratio is 1.12:0.6:0.2:0.2, and they are mixed evenly, and the raw materials are fully mixed by spray drying at 400°C to obtain a solid powder, and then The solid powder is ball milled and mixed with flux LiCl to obtain a mixture. Under the air atmosphere, heat the mixture from 600°C / h to 400°C for 5 hours, continue to heat up to 950°C at 500°C / h and sinter for 18 hours, cool to room temperature, wash and dry, and pass through a 400-mesh screen to obtain single crystal nickel Lithium cobalt manganese oxide cathode material, its chemical formula is LiNi 0.6 co 0.2 mn 0.2 o 2 . The prepared single crystal nickel cobalt lithium manganese oxide positive electrode material was subjected to scanning electron microscopy, and the results were as follows image 3 As shown, it shows that the prepared single crystal nickel cobalt lithium manganese oxide positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com