Sliding main bearing transmission chain and doubly-fed wind turbine including same

A technology for wind turbines and main bearings, applied in wind turbines, engines, machines/engines, etc., can solve the problems of unstable and reliable work, short bearing life, low bearing capacity, etc., to shorten the production cycle, good shock resistance, The effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

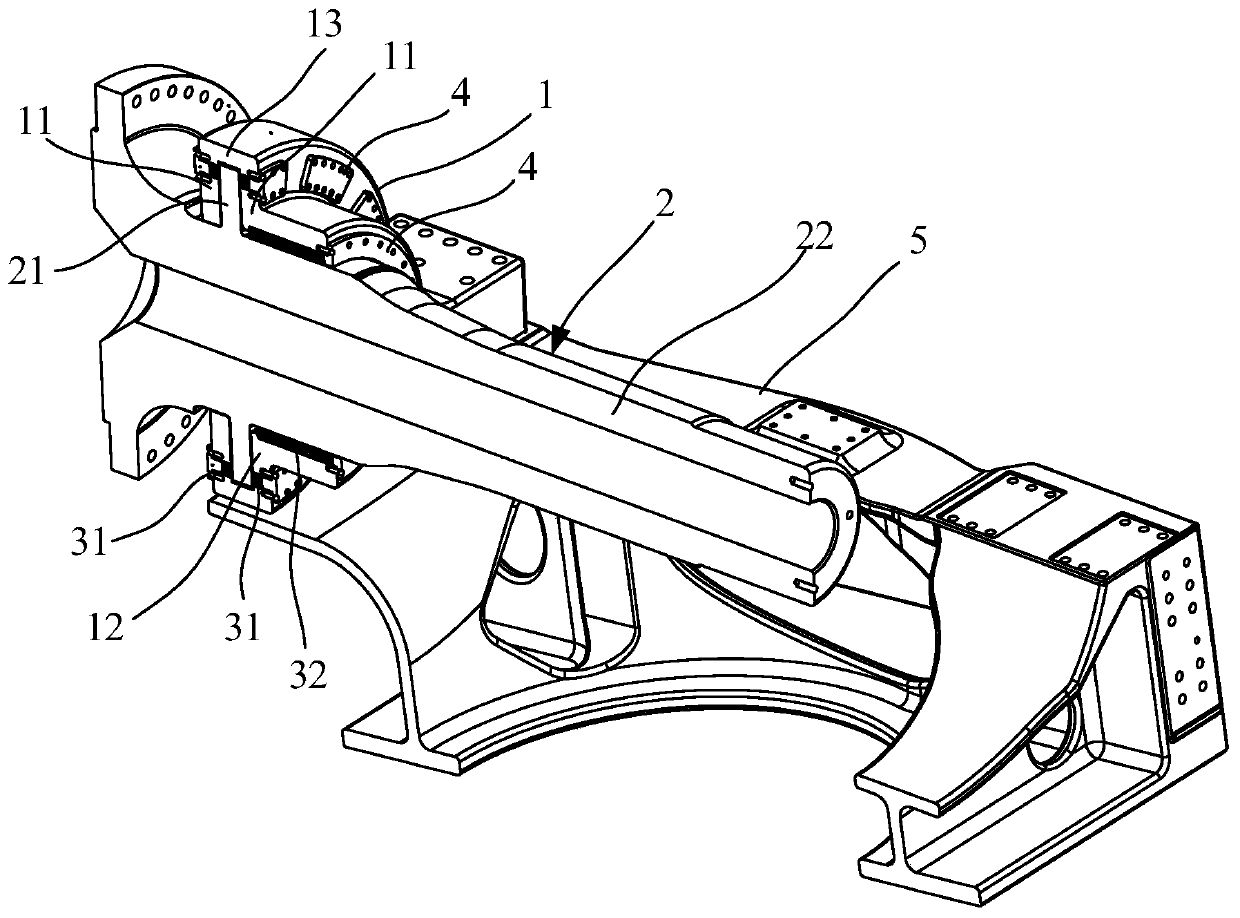

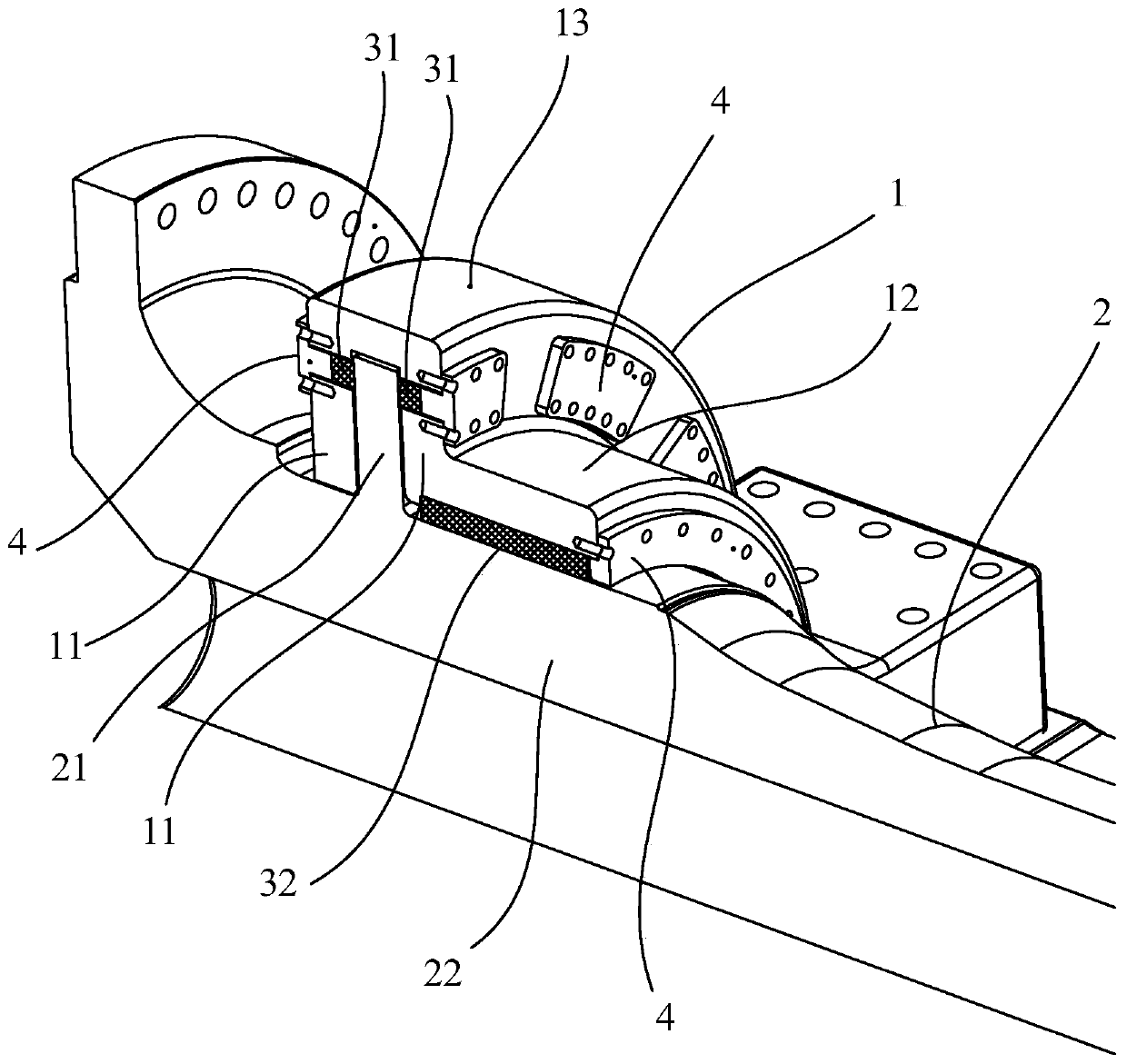

[0038] Such as Figure 1-Figure 3 As shown, this embodiment discloses a sliding main bearing transmission chain, wherein the sliding main bearing transmission chain includes a main bearing outer ring 1 , a bearing inner ring 2 , an axial slider 31 and a radial slider 32 .

[0039] Such as figure 1 and figure 2 As shown, the sliding main bearing transmission chain of this embodiment includes a bearing inner ring 2 and a main bearing outer ring 1, the bearing inner ring 2 has a radially outwardly protruding shoulder 21 and an inner ring body extending axially 22. The main bearing outer ring 1 has axial end plates 11 arranged on both axial sides of the shaft shoulder 21 and an axial extension 12 extending in the axial direction.

[0040] Such as figure 1 and figure 2 As shown, the sliding main bearing transmission chain of this embodiment includes two sets of axial sliders 31, and the two sets of axial sliders 31 are respectively accommodated in the axial end plates 11 on b...

Embodiment 2

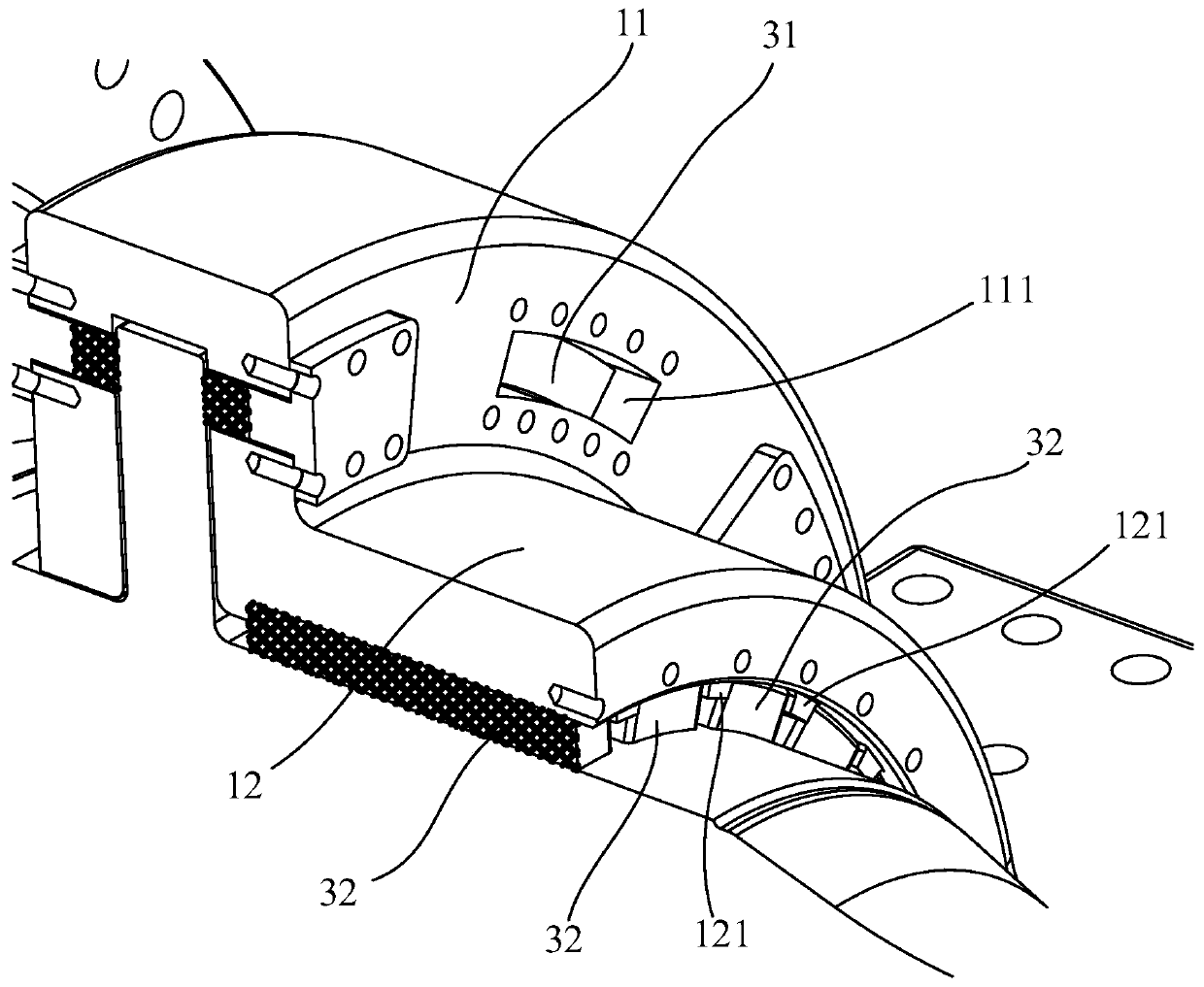

[0062] Such as Figure 4 and Figure 5 As shown, other parts of the sliding main bearing transmission chain in this embodiment are the same as those in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that there are multiple axial extensions 12 .

[0063] Among them, such as Figure 4 and Figure 5 As shown, the left axial extension 12 of this embodiment is integrally connected with the axial end plate 11 . The right axial extension 12 is separated from the axial end plate 11 . When a plurality of axially extending parts 12 are provided, the bending strength of the inner ring body 22 can be greatly enhanced through distribution in the axial direction of the inner ring body 22 .

[0064] Such as Figure 5 As shown, in this embodiment, both axial sides of the right axial extension 12 separated from the axial end plate 11 are provided with end face pressure plates 4 . Such as Figure 4 The axially outward side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com