An electric heating film, its preparation method and electric heating product

A technology of electric heating film and heating layer, which is applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., to achieve the effect of prolonging service life and stabilizing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of electrothermal film, comprises the steps:

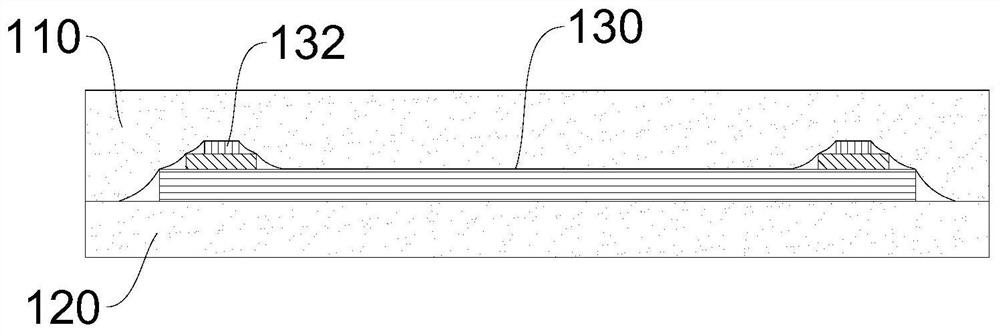

[0049] (1) Forming a film on the surface of the base material with conductive ink to prepare the heat generating layer 130 . The heating layer 130 is made by forming a film on the surface of the substrate using a conductive ink made of a low-temperature softening resin and a conductive filler. The substrate is one or a combination of films, plates, and fabrics. The substrate may also be the first protective layer 110 or the second protective layer 120 or other film-forming substrates.

[0050] Optionally, the heating layer 130 is formed by forming a film on the surface of the base material at one time by using conductive ink. Avoid using multiple coatings or multi-layer stacking to achieve different thicknesses of the heating area 131 and the confluence area 132, and can make the continuous transition between the heating area 131 and the confluence area 132, so that the heating of the heating film i...

Embodiment 1

[0060] The conductive ink containing epoxy resin with a softening temperature of 70-80°C (for example: 70°C, 75°C or 80°C) is used as raw material, wherein the mass percentage of epoxy resin in non-volatile components is 20%.

[0061] Cylindrical coating rollers with different meshes are used to coat the epoxy resin substrate, and after drying, a heat generating layer 130 with a three-dimensional structure is formed. Wherein, on the coating roller, the mesh in the heating zone 131 is a shallow hole of 250 meshes, the confluence region 132 is a deep hole of 100 meshes, and the junction area transitions gradually with a gradient of 30 meshes / 100 microns. A 1 cm wide section in the middle of the applicator roll junction 132 used 150 mesh orifices.

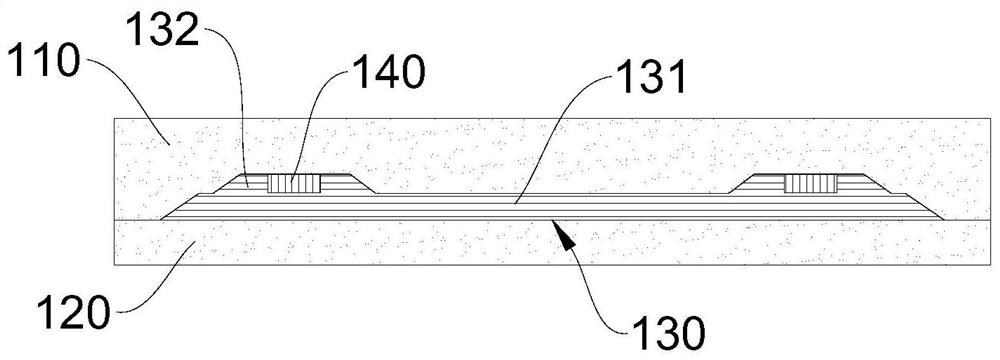

[0062] The produced heat generating layer 130 has a continuous planar structure. see figure 1 According to the test, the thickness of the heating area 131 is 5 microns, the thickness of the confluence area 132 is 50 microns, and the...

Embodiment 2

[0065] Use conductive inks containing ethylene-vinyl acetate copolymer resins with a softening temperature of 80-100°C (for example: 80°C, 85°C or 100°C) as raw materials, of which ethylene-vinyl acetate copolymer resins account for the total non-volatile components 40%.

[0066] Gravure printing rolls with different meshes are used to coat the PET film, and after drying, a heat generating layer 130 with a three-dimensional structure is formed. Wherein, the mesh in the heating zone 131 on the coating roller is a 200-mesh shallow hole, the confluence zone 132 is a 100-mesh deep hole, and the junction area transitions gradually with a gradient of 20 mesh / 100 microns. A 1 cm wide portion in the middle of the confluence region 132 of the gravure roll used 150 mesh holes.

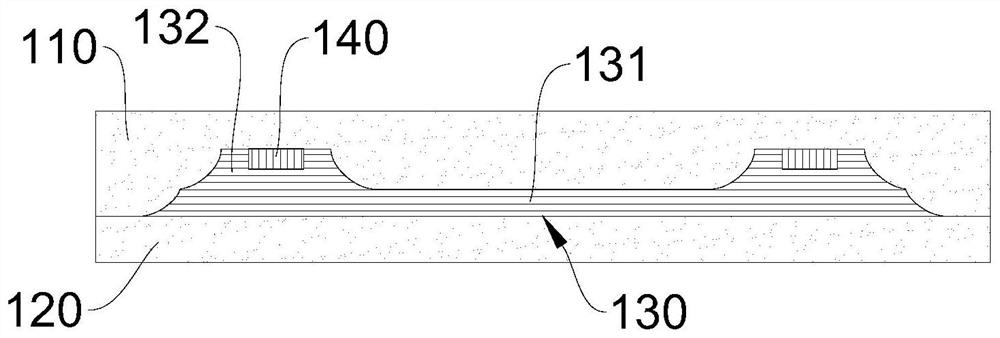

[0067] The produced heat generating layer 130 has a striped structure. see figure 2 According to tests, the thickness of the heating zone 131 is 10 microns, the thickness of the confluence zone 132 is 35 mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com