Production process and production equipment of inorganic modified graphite non-combustible insulation board

A technology of inorganic modification and production process, applied in the field of building materials, can solve problems such as poor impact resistance, difficult pressure adjustment, insufficient tightness of insulation boards, etc., to achieve the effect of enhancing elasticity and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

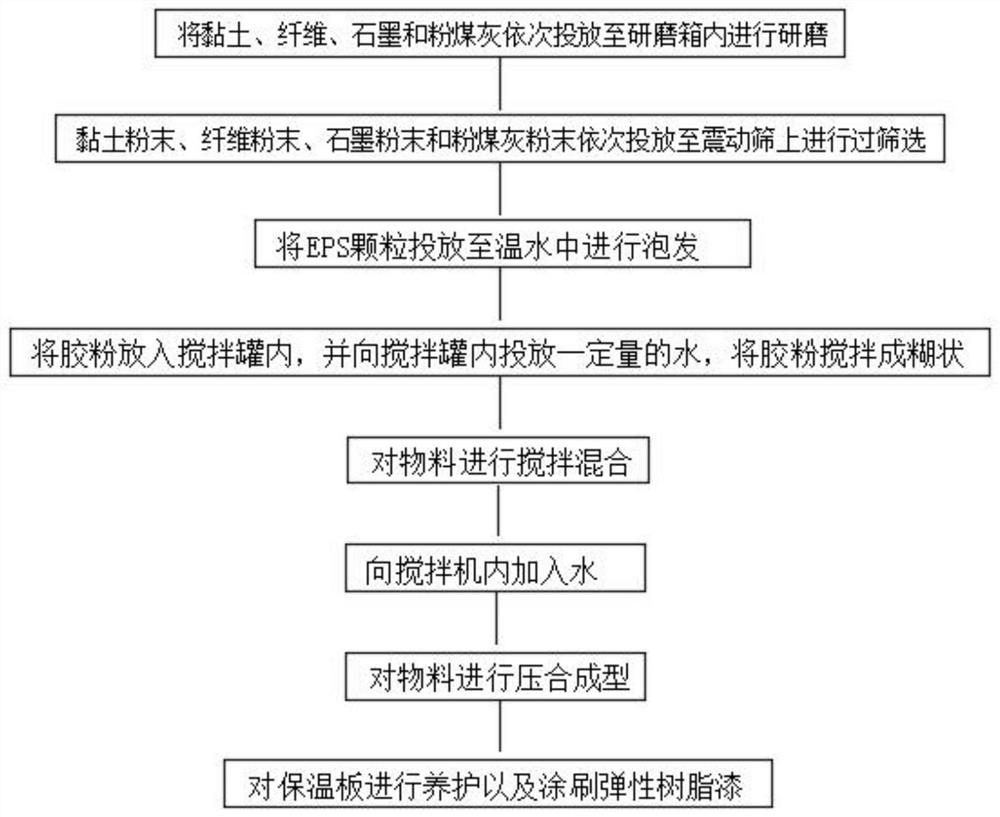

[0034] refer to figure 1 , a production process of inorganic modified graphite non-combustible insulation board is proposed in this example, including the following raw materials in parts by weight: 10 parts of cement, 6 parts of EPS particles, 1 part of rubber powder, 30 parts of fiber, 20 parts of sand, clay 10 parts, graphite 30 parts, fly ash 10 parts and elastic resin paint 10 parts.

[0035] This embodiment includes the following steps:

[0036] S1. First put clay, fiber, graphite and fly ash into the grinding box for grinding;

[0037] S2, putting the clay powder, fiber powder, graphite powder and fly ash powder onto the vibrating sieve in turn for sieving, so as to ensure that the clay powder, graphite powder and fly ash powder are particles of uniform size;

[0038] S3, putting the EPS particles into warm water for foaming;

[0039] S4, put the rubber powder into the mixing tank, and put a certain amount of water into the mixing tank, and stir the rubber powder int...

Embodiment 2

[0045] refer to figure 1 , a production process of inorganic modified graphite non-combustible insulation board is proposed in this example, including the following raw materials in parts by weight: 20 parts of cement, 7 parts of EPS particles, 2 parts of rubber powder, 40 parts of fiber, 30 parts of sand, clay 20 parts, 40 parts of graphite, 20 parts of fly ash and 20 parts of elastic resin paint.

[0046] This embodiment includes the following steps:

[0047] S1. First put clay, fiber, graphite and fly ash into the grinding box for grinding;

[0048] S2, putting the clay powder, fiber powder, graphite powder and fly ash powder onto the vibrating sieve in turn for sieving, so as to ensure that the clay powder, graphite powder and fly ash powder are particles of uniform size;

[0049] S3, putting the EPS particles into warm water for foaming;

[0050] S4, put the rubber powder into the mixing tank, and put a certain amount of water into the mixing tank, and stir the rubber ...

Embodiment 3

[0056] refer to figure 1 , a production process of inorganic modified graphite non-combustible insulation board is proposed in this example, including the following raw materials in parts by weight: 30 parts of cement, 8 parts of EPS particles, 3 parts of rubber powder, 50 parts of fiber, 40 parts of sand, clay 30 parts, graphite 50 parts, fly ash 30 parts and elastic resin paint 30 parts.

[0057] This embodiment includes the following steps:

[0058] S1. First put clay, fiber, graphite and fly ash into the grinding box for grinding;

[0059] S2, putting the clay powder, fiber powder, graphite powder and fly ash powder onto the vibrating sieve in turn for sieving, so as to ensure that the clay powder, graphite powder and fly ash powder are particles of uniform size;

[0060] S3, putting the EPS particles into warm water for foaming;

[0061] S4, put the rubber powder into the mixing tank, and put a certain amount of water into the mixing tank, and stir the rubber powder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com