Multi-heterojunction interface perovskite solar cell and preparation method thereof

A solar cell and multi-heterojunction technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low charge carrier mobility, insufficient heterojunction interface, and large exciton binding energy, etc. Photoelectric conversion efficiency, conducive to industrial production, overcoming the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

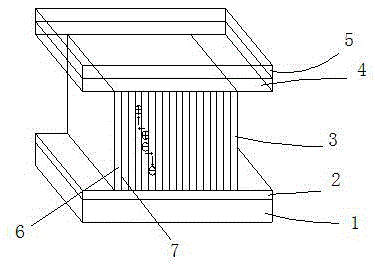

[0019] Such as figure 1 A multi-heterojunction interface perovskite solar cell is shown, which adopts a vertically grown multi-planar heterojunction interface structure, including FTO glass 1, dense layer 2, multi-heterojunction interface layer 3, and hole transport layer 4. The back electrode 5; the dense layer 2 is set on the FTO glass 1, the multi-heterojunction interface layer 3 grows on the dense layer 2 in the form of multi-layer upright sheets, and the back electrode 5 is set on the multi-heterojunction interface layer 3, located on the hole transport layer 4; the multi-heterojunction interface layer 3 is composed of a plurality of vertically grown nanosheets 6 and light absorbers 7 filled between the nanosheets.

[0020] The pitch of the nano-sheets 6 is between 20-200nm, and the height of the nano-sheets 6 is between 100-500nm.

[0021] The nanosheet 6 adopts ZnO or TiO 2 .

[0022] The light absorber 7 adopts CH 3 NH 3 PB 3-x Cl x or CH 3 NH 3 PB 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com