Conjugate cam jacquard shedding device

A technology of conjugate cam and jacquard opening, which is applied in the fields of jacquard machines, textiles, textiles and papermaking, etc., can solve problems affecting the accuracy of reciprocating motion, complex structure design of swing parts, and irregular loads, so as to avoid structural design defects and facilitate Effects of reduced assembly, maintenance, and repair workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

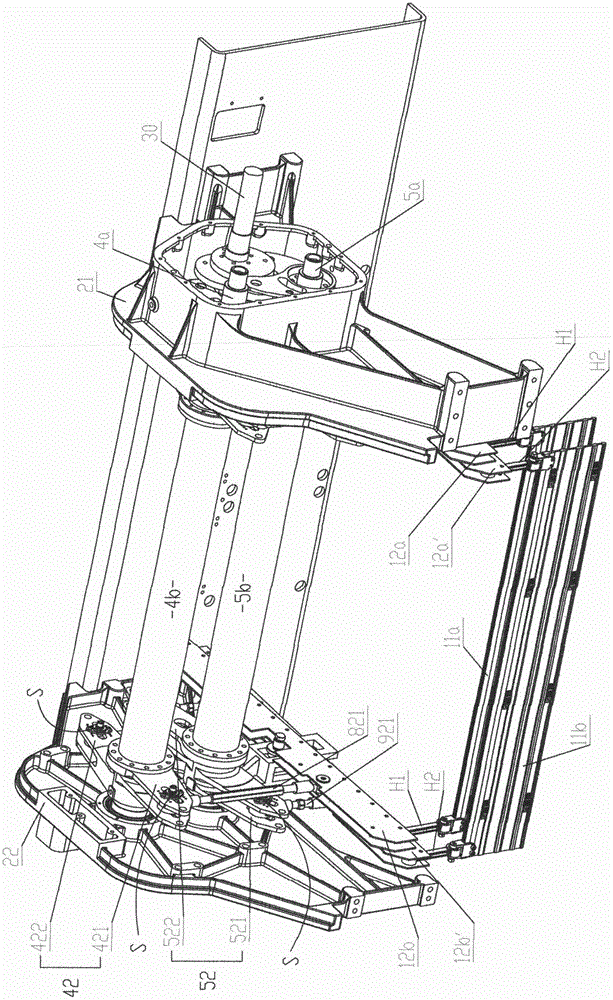

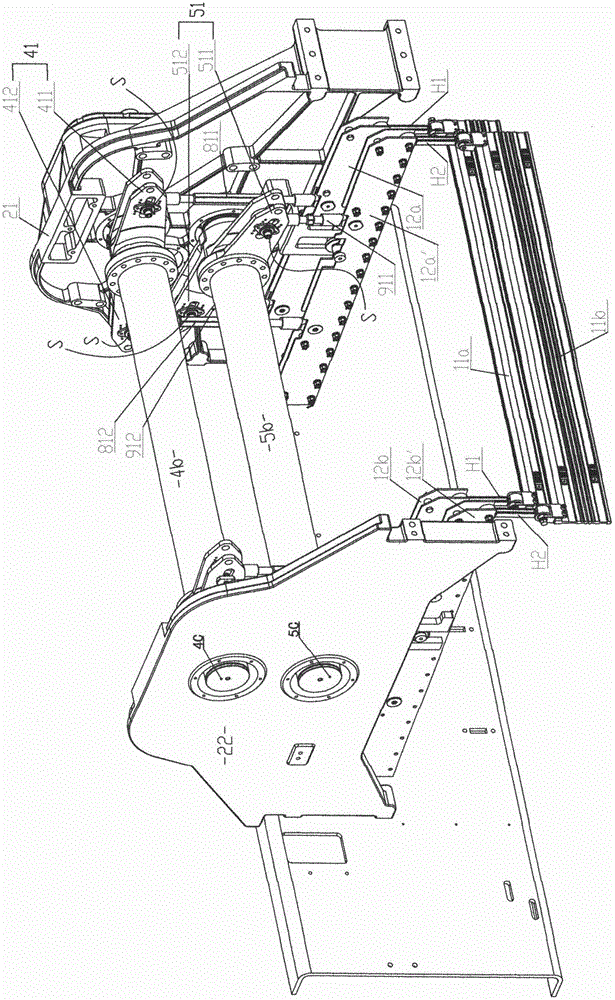

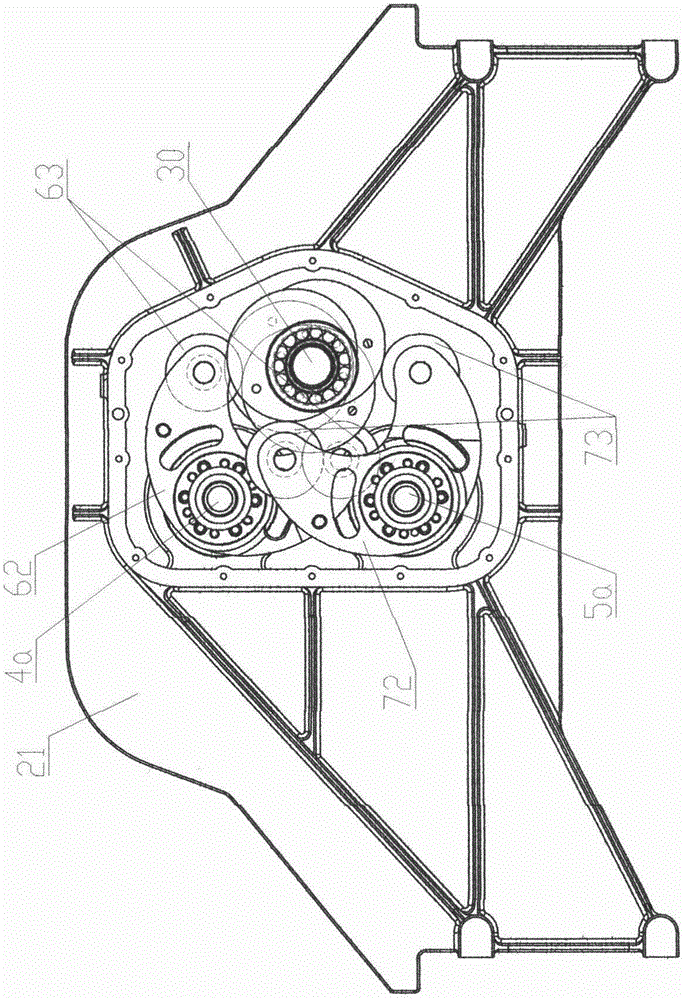

[0030] see figure 1 , 2 , 3, 4, 5, 6, 7, and 8 are preferred embodiments of the present invention.

[0031] Such as figure 1 , 2 Shown, known knife lifting mechanism comprises two groups of lifting knives, two pairs of knife rests and some suspenders. Its left and right ends of the lifting knife group 11a when it is at the top dead center position are suspended and connected to a pair of knife rests made up of knife rests 12a, 12b through several suspension rods H1, and the lifting knife group 11a when it is at the bottom dead center position The left and right ends of the knife set 11b are suspended and connected to a pair of knife rests consisting of knife rests 12a' and 12b' through a number of suspension rods H2.

[0032] Both the knife lifting group 11a and the knife lifting group 11b are arranged longitudinally and spaced between the box-type side wall panels 21 and the plate-type side wall panels 22 by a number of equal-length lifting knives. The lifting knives i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com