Novel coke powder cooling device

A technology of cooling device and coke powder, which is applied in coke cooling, coke oven, petroleum industry, etc. It can solve the problems of difficult sealing at the bottom water jacket, slow cooling speed of cooling jacket, and heavy maintenance workload, etc., to achieve reduction Small maintenance workload, improved cooling efficiency, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

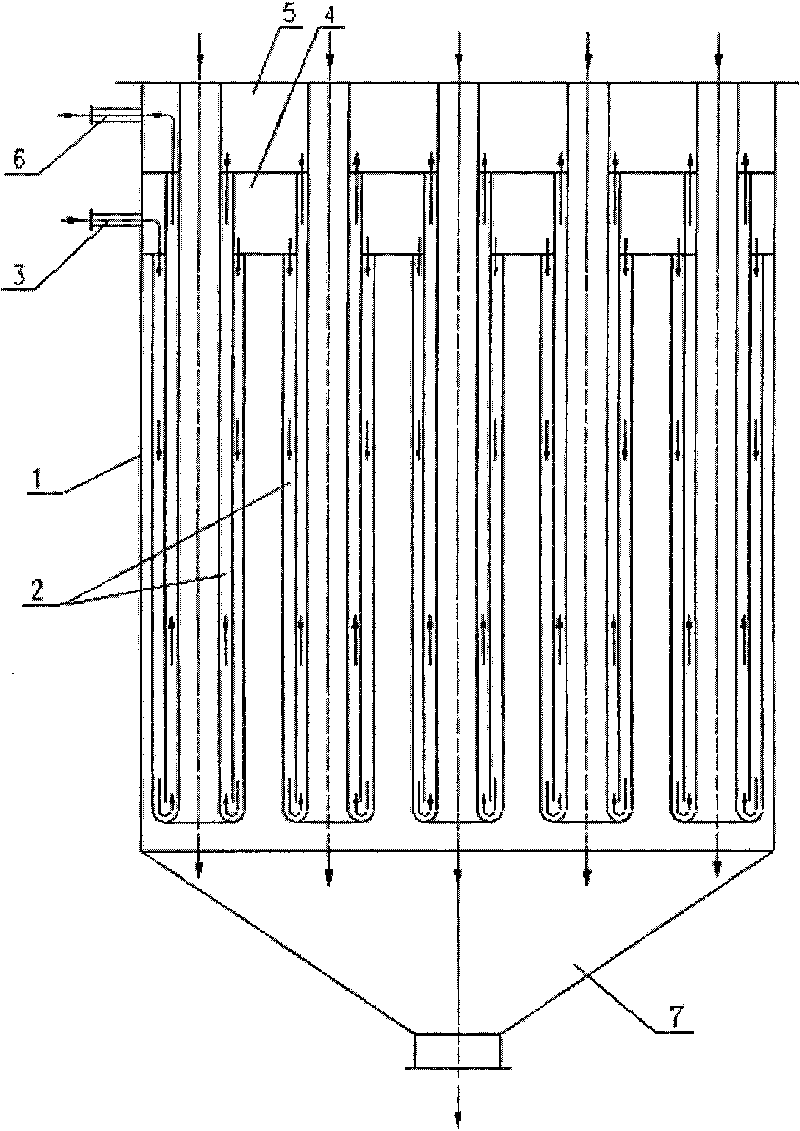

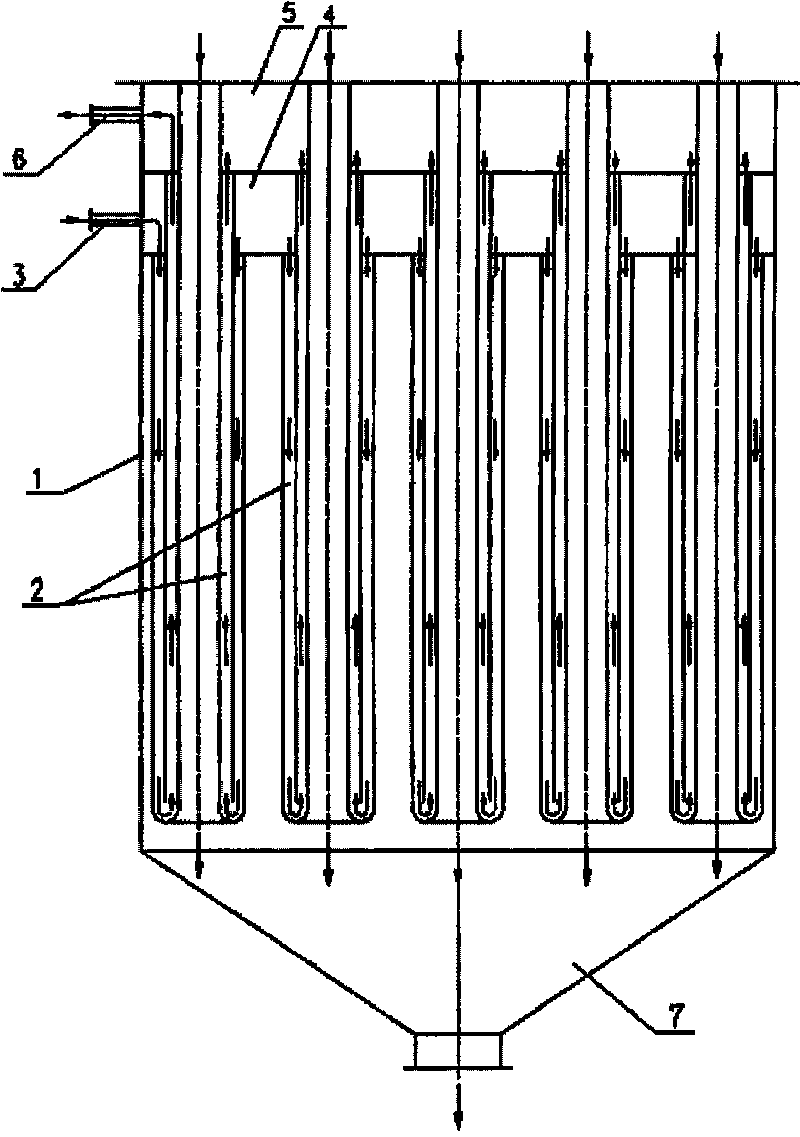

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] See figure 1 , a new type of coke powder cooling device, which is composed of a casing 1, cooling pipe 2, water inlet distribution box 4, water outlet header 5, water inlet pipe 3, and water outlet pipe 6, and multiple groups of parallel cooling pipes 2 are hung on the casing 1 upper part, the water inlet pipe 3 and the water outlet pipe 6 arranged on the upper part of the casing 1 are respectively connected with the water inlet distribution box 4 and the water outlet header box 5 arranged on the top of the cooling pipe 2.

[0014] The cooling pipe 2 is a "U"-shaped structure and is arranged vertically. Both the water inlet and the water outlet are on the upper side.

[0015] When the present invention works, the high-temperature coke powder at 800-900°C to be cooled enters the flow channel between the cooling pipes 2, and cooling water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com