Efficient and oxygen-permeable ITO target material placing and sintering method

A sintering method and target technology, which are applied in the field of high-efficiency oxygen-permeable ITO target placement-sintering, can solve the problems of long processing time, increased process difficulty and process cost, and large grinding volume in grinding operations, and achieve high temperature resistance. Excellent performance, reducing target consumption and avoiding structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-efficiency oxygen-permeable ITO target placement-sintering method, the steps are as follows:

[0037] 1) Prepare the ITO target blank by slip casting, and then dry it at 200°C for 80h;

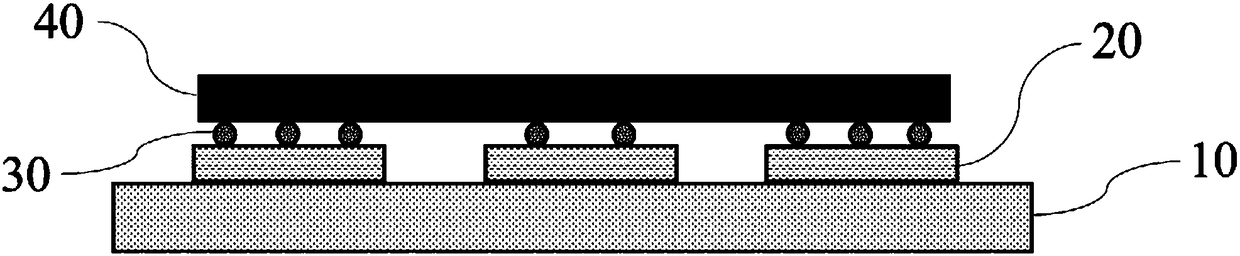

[0038] 2) Place the gasket on the corundum-mullite setter, place a layer of zirconia balls (zirconia content>98%) with a diameter of 0.5mm on the gasket, and then place the ITO target blank on the zirconia On the ball (the placement of the ITO target blank is as follows: figure 1 shown);

[0039] 3) Put the setter plate with the ITO target blank set in step 2) into the sintering furnace, and sinter at 1200°C for 35 hours to obtain the ITO target (the photo of the bottom surface is as follows figure 2 shown), and then the ITO target is polished to obtain the finished ITO target.

[0040] Depend on figure 2 It can be seen that the ITO target material presents a deep black after sintering, which is the performance of the high density of the ITO target material. Since the zirc...

Embodiment 2

[0042] A high-efficiency oxygen-permeable ITO target placement-sintering method, the steps are as follows:

[0043] 1) Prepare the ITO target blank by cold pressing, and then dry it at 300°C for 70h;

[0044] 2) Place the gasket on the corundum-mullite setter, place a layer of zirconia balls (zirconia content>98%) with a diameter of 0.8mm on the gasket, and then place the ITO target blank on the zirconia On the ball (the placement of the ITO target blank is as follows: figure 1 shown);

[0045] 3) Put the setter with the ITO target blank set in step 2) into the sintering furnace, and sinter at 1400° C. for 20 hours to obtain the ITO target, and then polish the ITO target to obtain the finished ITO target.

Embodiment 3

[0047] A high-efficiency oxygen-permeable ITO target placement-sintering method, the steps are as follows:

[0048] 1) Prepare the ITO target blank by slip casting, and then dry it at 450°C for 50h;

[0049] 2) Place the gasket on the calcium silicate setter, place a layer of zirconia balls with a diameter of 1mm (zirconia content>98%) on the gasket, and then place the ITO target blank on the zirconia balls ( The placement of ITO target blanks is as follows: figure 1 shown);

[0050] 3) Put the setter with the ITO target blank set in step 2) into a sintering furnace, and sinter at 1600°C for 30 hours to obtain an ITO target, and then polish the ITO target to obtain a finished ITO target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com