Batch-type uniform-speed discharging stirring device and construction method for self-leveling terrace

A stirring device and intermittent technology, which is applied in the field of fast-discharging stirring devices, can solve the problems of fracture, insufficient uniformity, low processing efficiency, etc., and achieve the effects of uniform and efficient mixing and overcoming structural defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

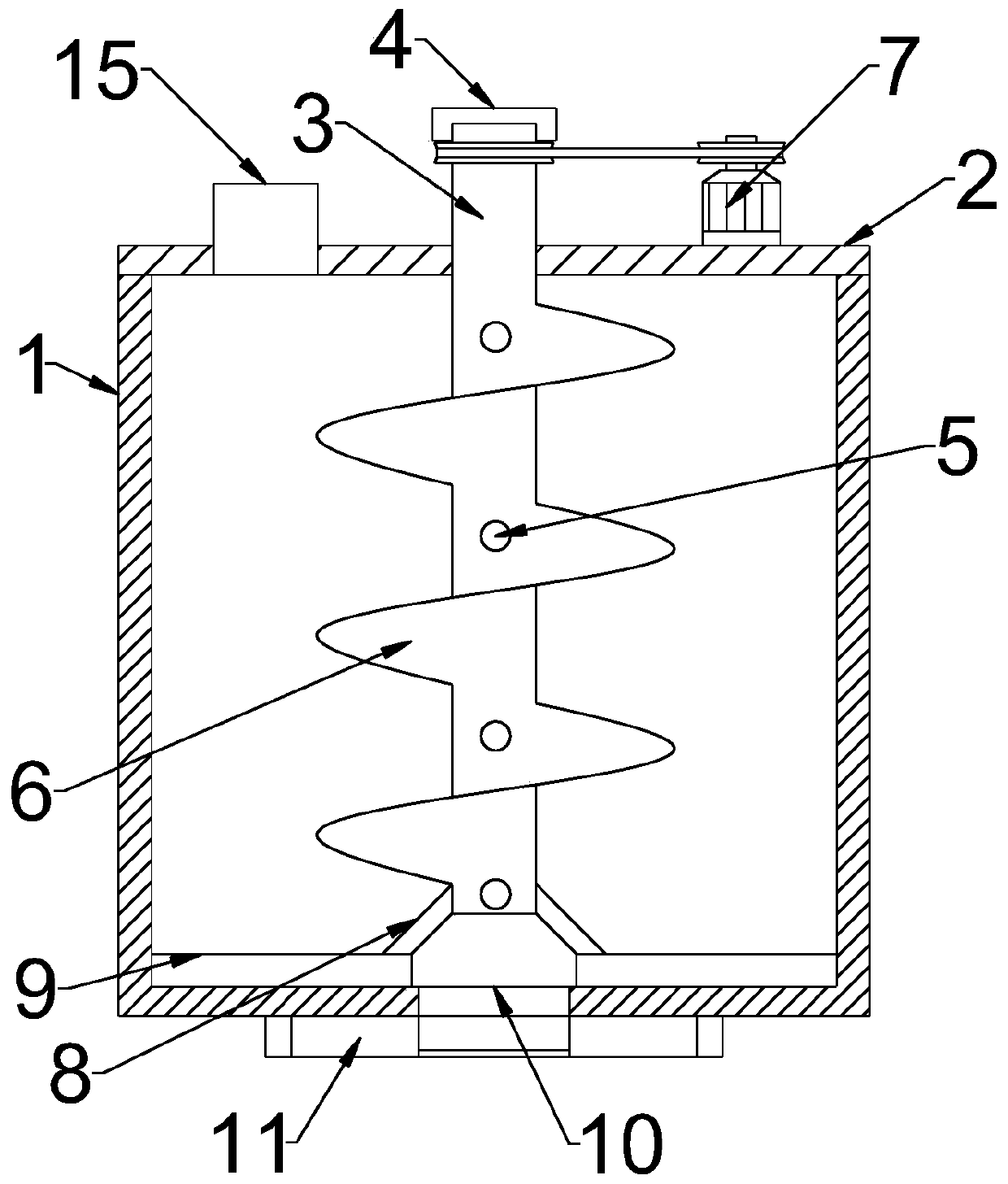

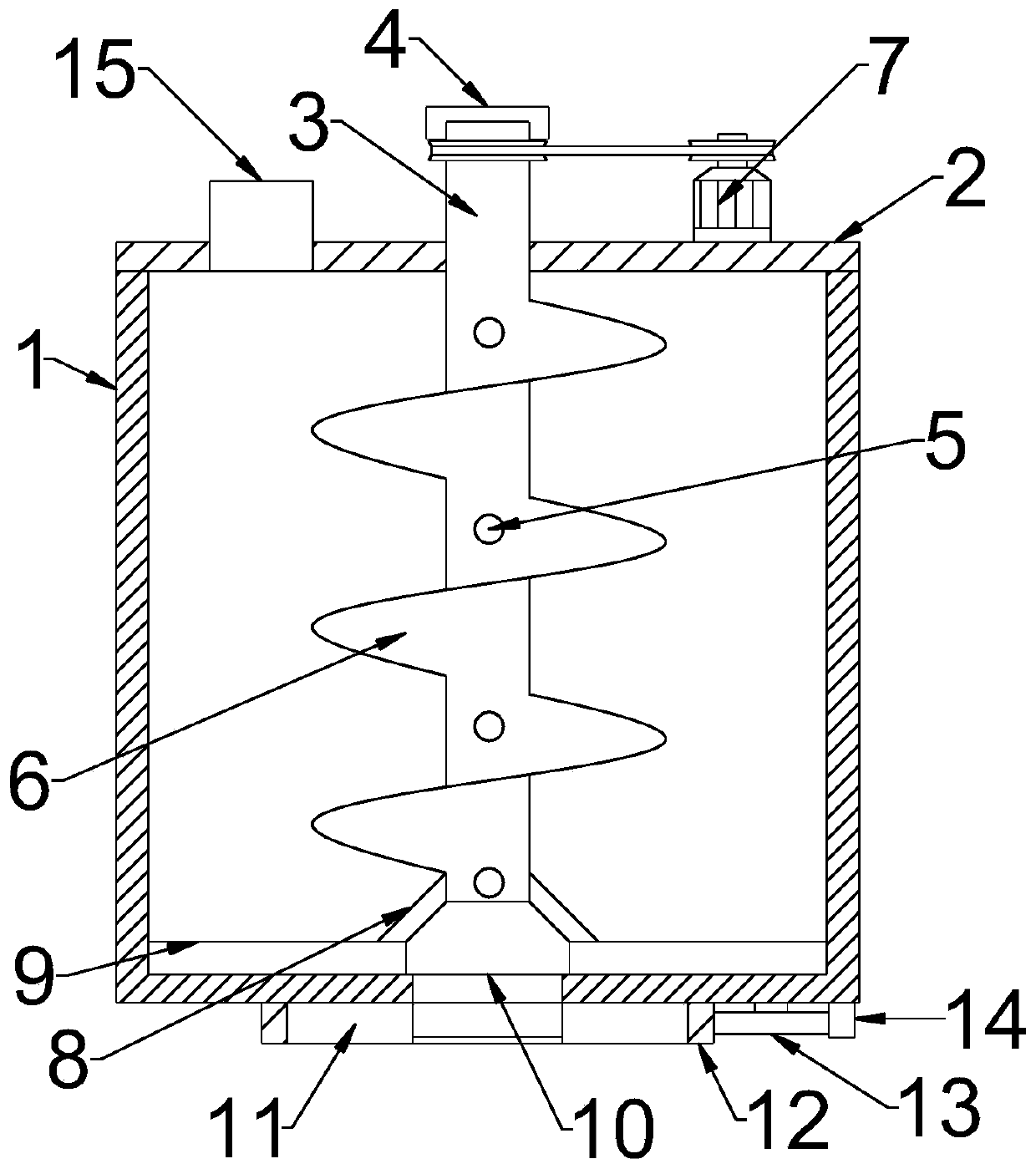

[0036] see figure 1 , in an embodiment of the present invention, a stirring device for intermittent constant-velocity discharge includes a kettle body structure composed of a housing 1 and an upper cover 2, the upper cover 2 is connected with a stirring mechanism, and the housing The lower end of the body 1 is provided with a discharge hole 10, and the stirring mechanism is composed of a rotating shaft 3 for introducing additives and connected with a spiral fan blade 6, and the upper end of the rotating shaft 3 is connected to a motor 7 for transmission.

[0037] The lower end of the housing 1 is located on the periphery of the discharge hole 10 and is connected with a discharge structure 11 . The discharge structure 11 has a valve mechanism for controlling the discharge hole 10 to discharge downward.

[0038] The upper end of the upper cover 2 is provided with a feed pipe 15 through which the material is put into the housing 1 through the feed pipe 15. The middle part of the ...

Embodiment 2

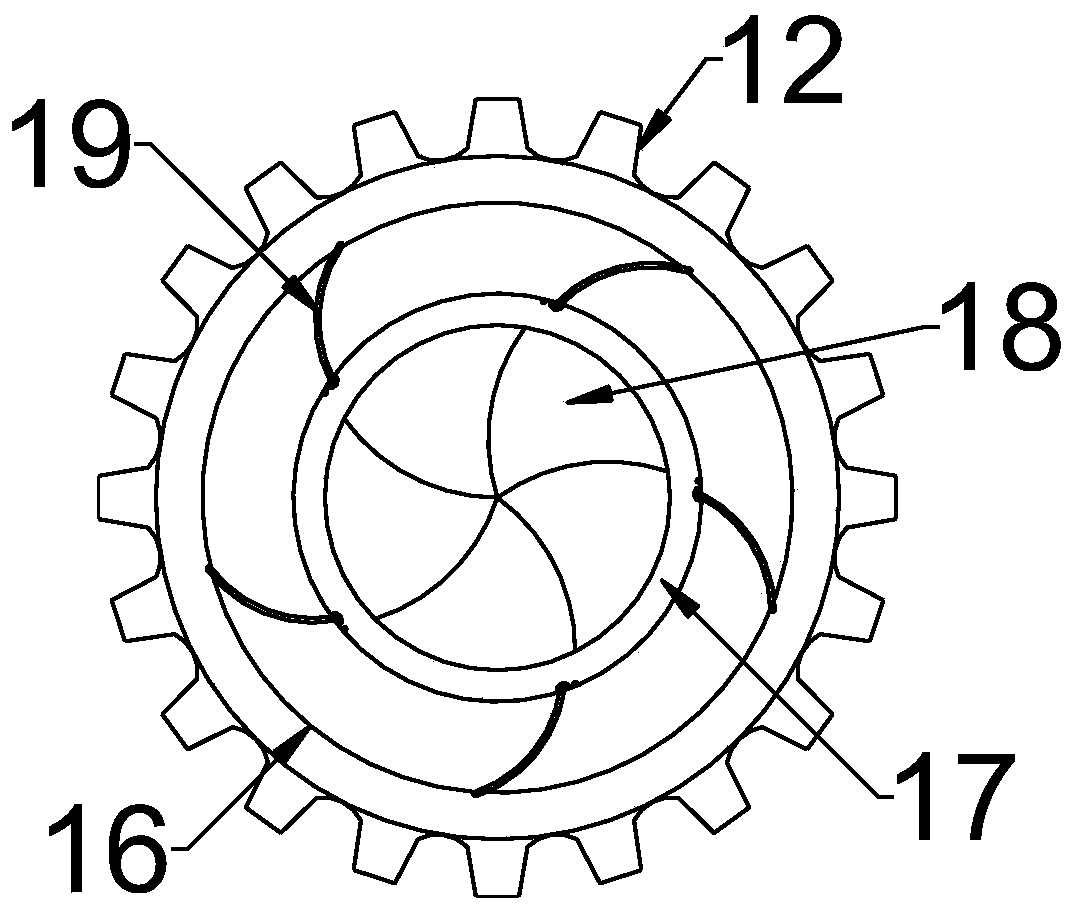

[0049] see Figure 2-6 , in the embodiment of the present invention, in practical application, in order to overcome the problem of limited self-flowing efficiency and insufficient uniformity of concrete in large-area construction, the construction base is usually separated, so that pumping construction is carried out on the separated independent small area, In order to achieve this effect, on the basis of Embodiment 1, a stirring device for intermittent constant-speed discharge, the discharge structure 11 is composed of an outer cylinder 16 that is rotatably connected to the bottom of the housing 1 and is riveted or welded. The inner cylinder 17 fixed on the bottom of the housing 1 is arranged concentrically. The outer cylinder 16 is located on the periphery of the inner cylinder 17. The inner cylinder 17 and the discharge hole 10 are arranged opposite and matched in size. The rotating connection is provided with five sets of discharge baffles 18 for controlling the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com