Patents

Literature

35results about How to "Mix evenly and efficiently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

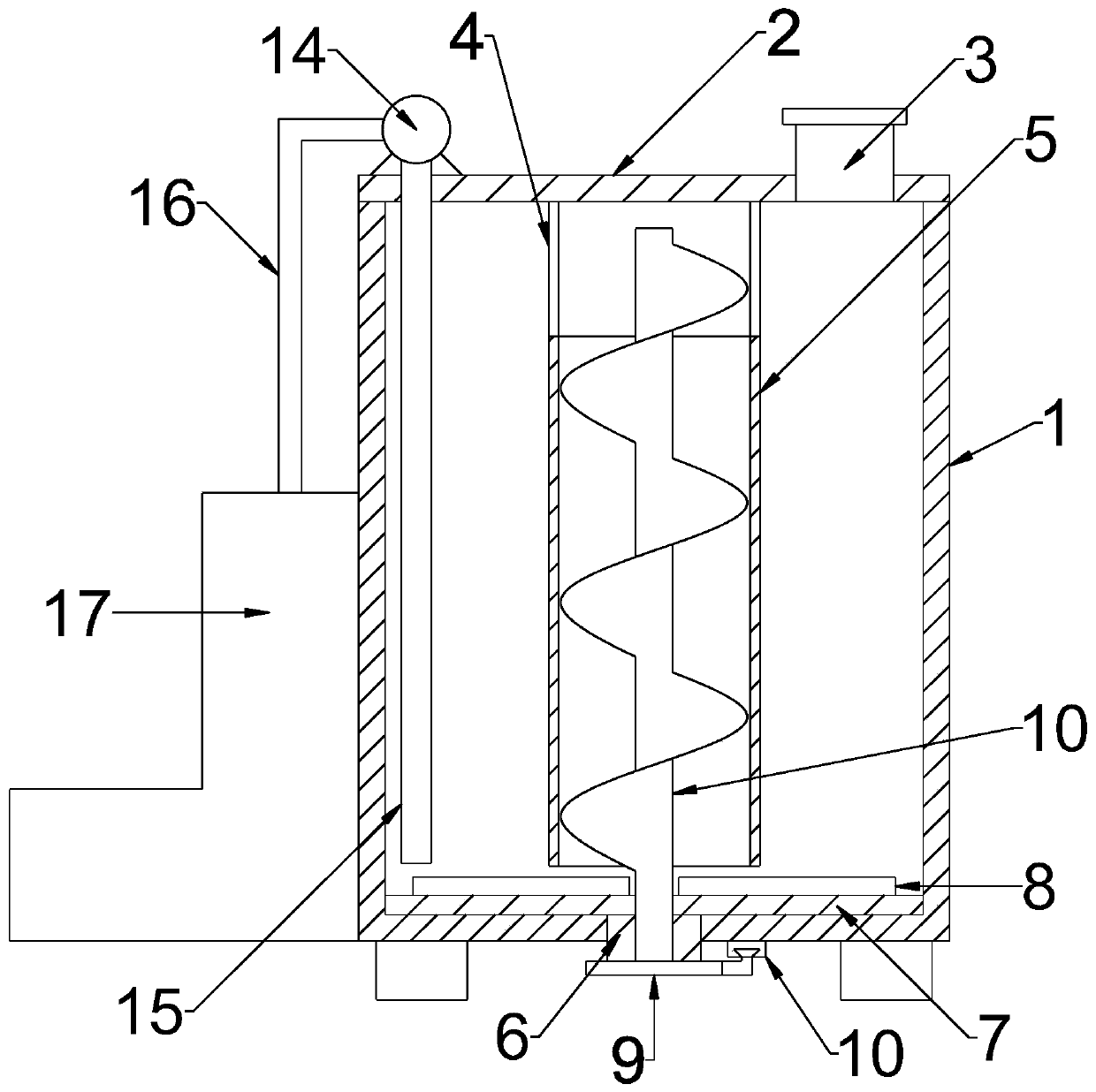

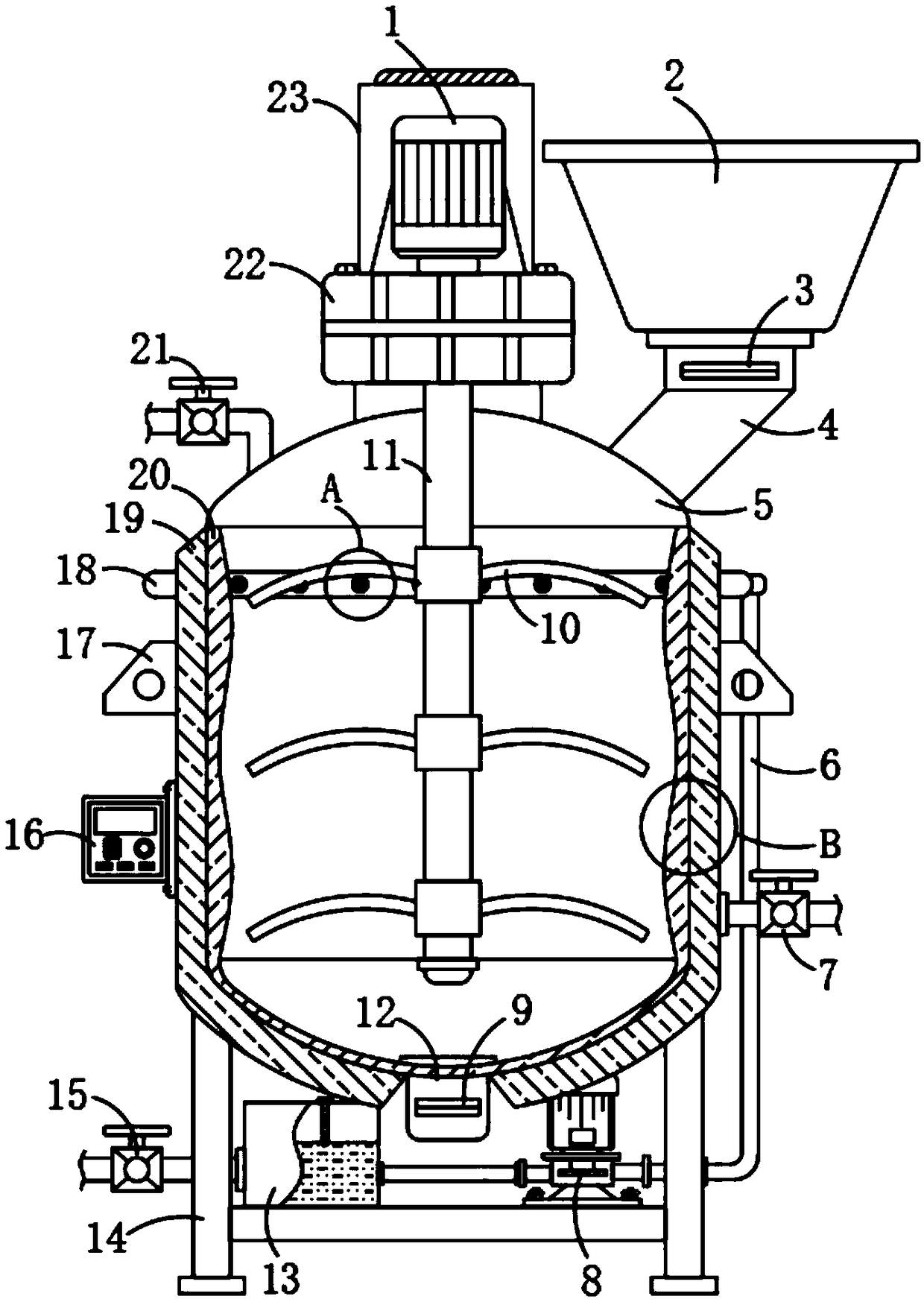

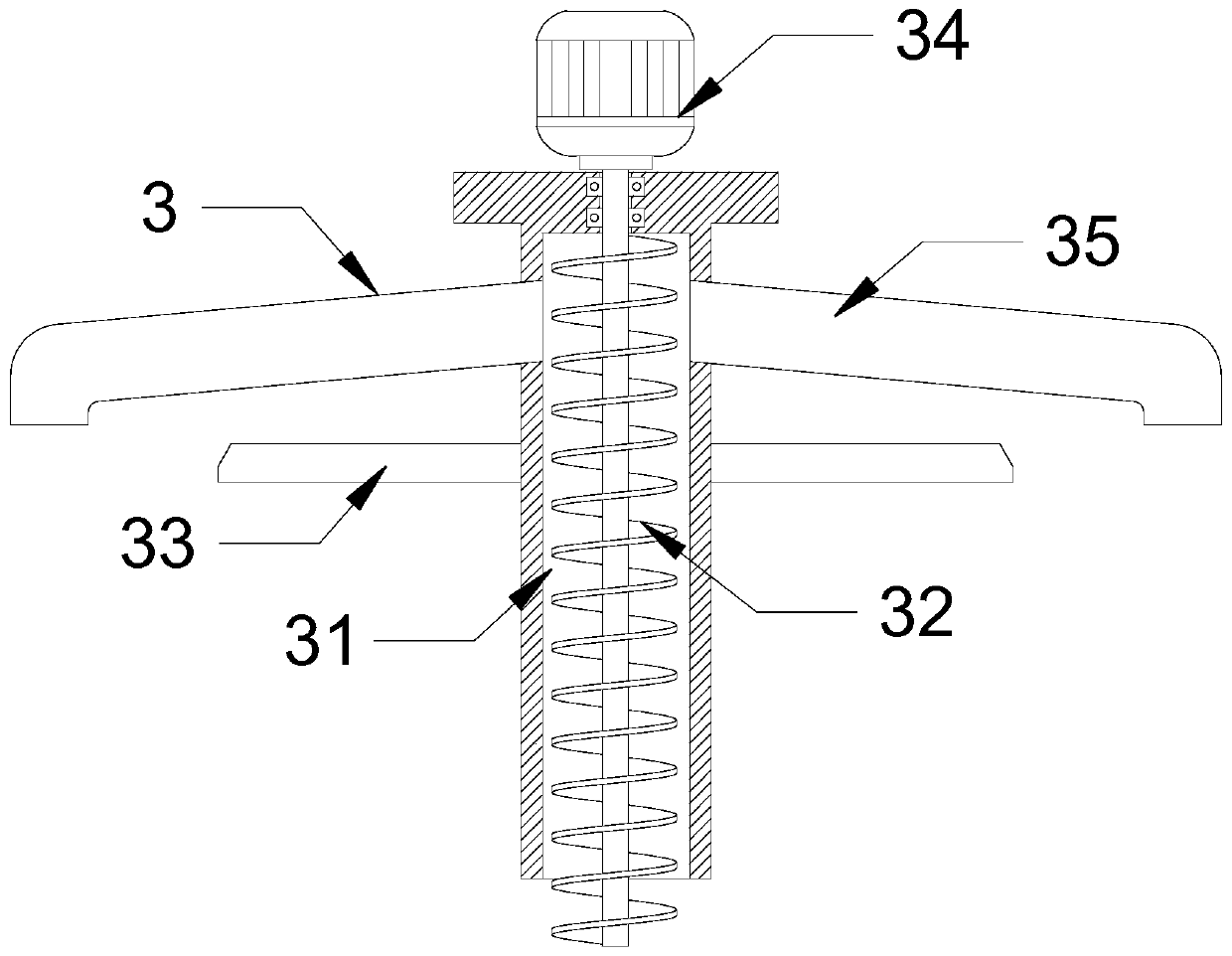

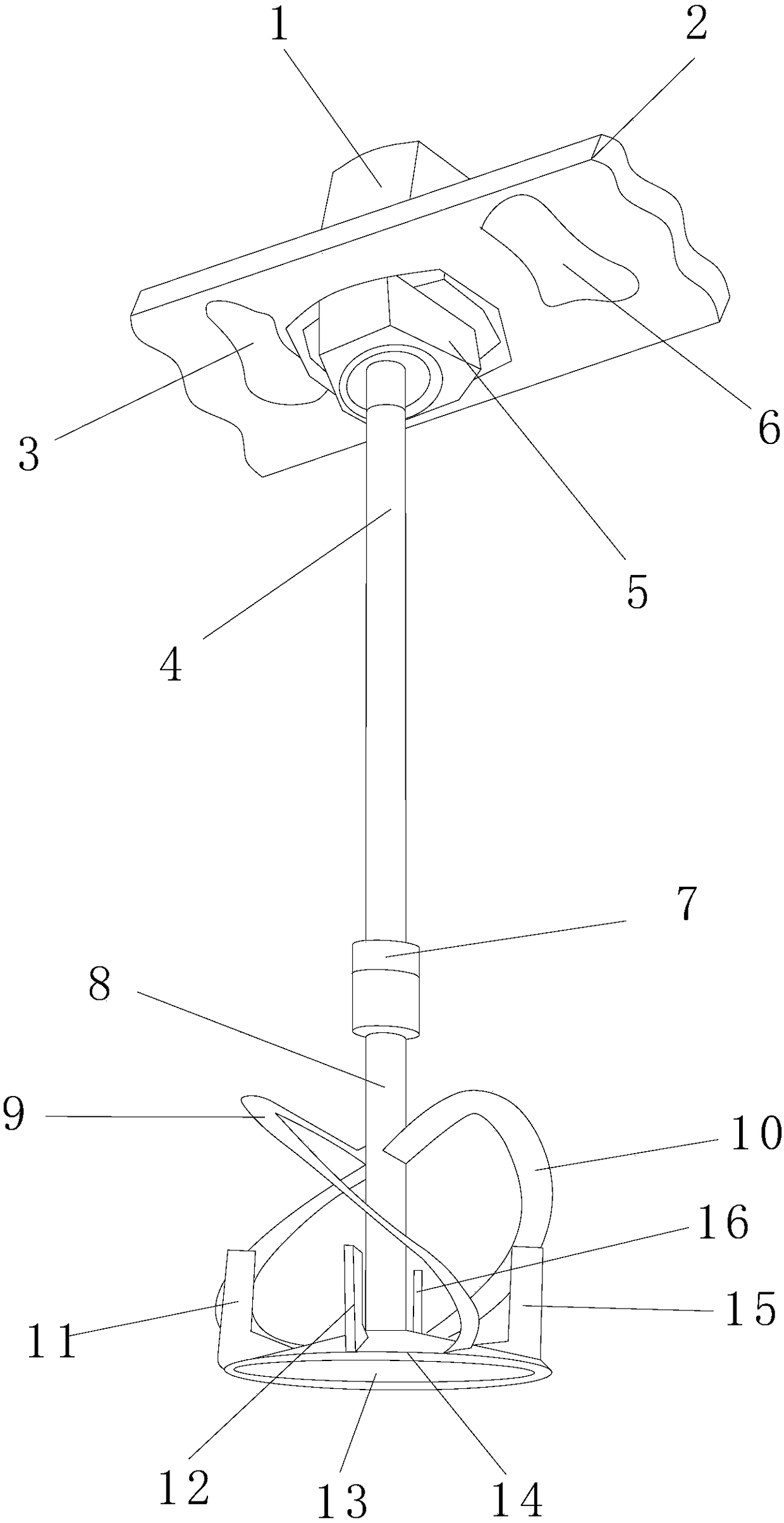

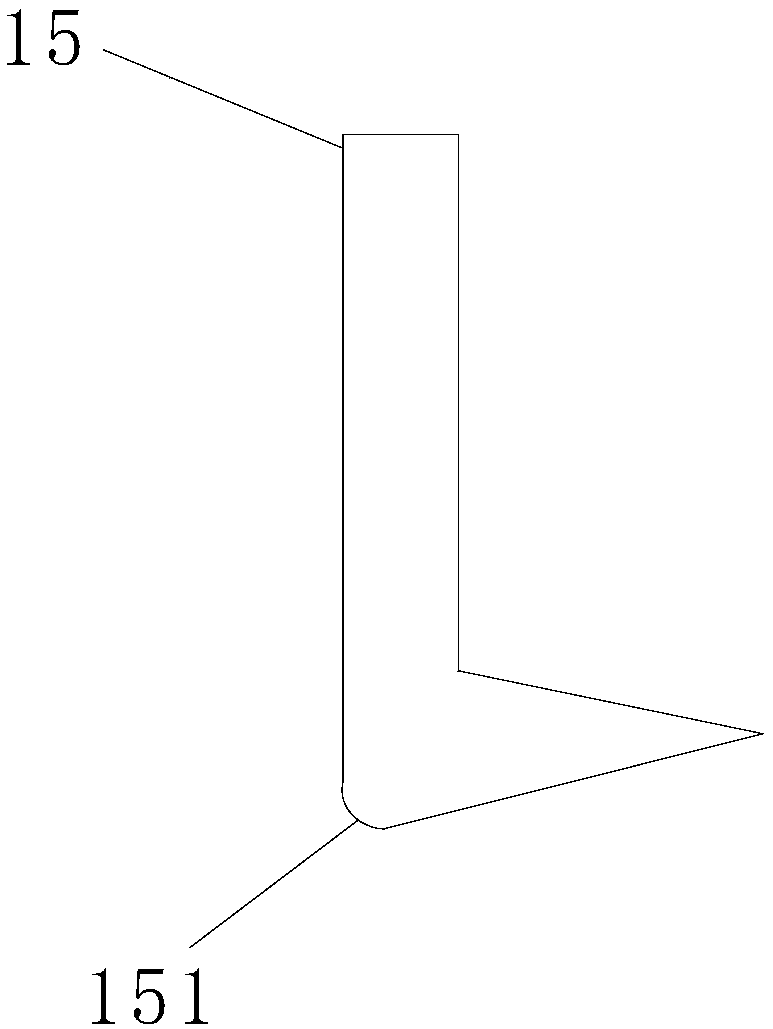

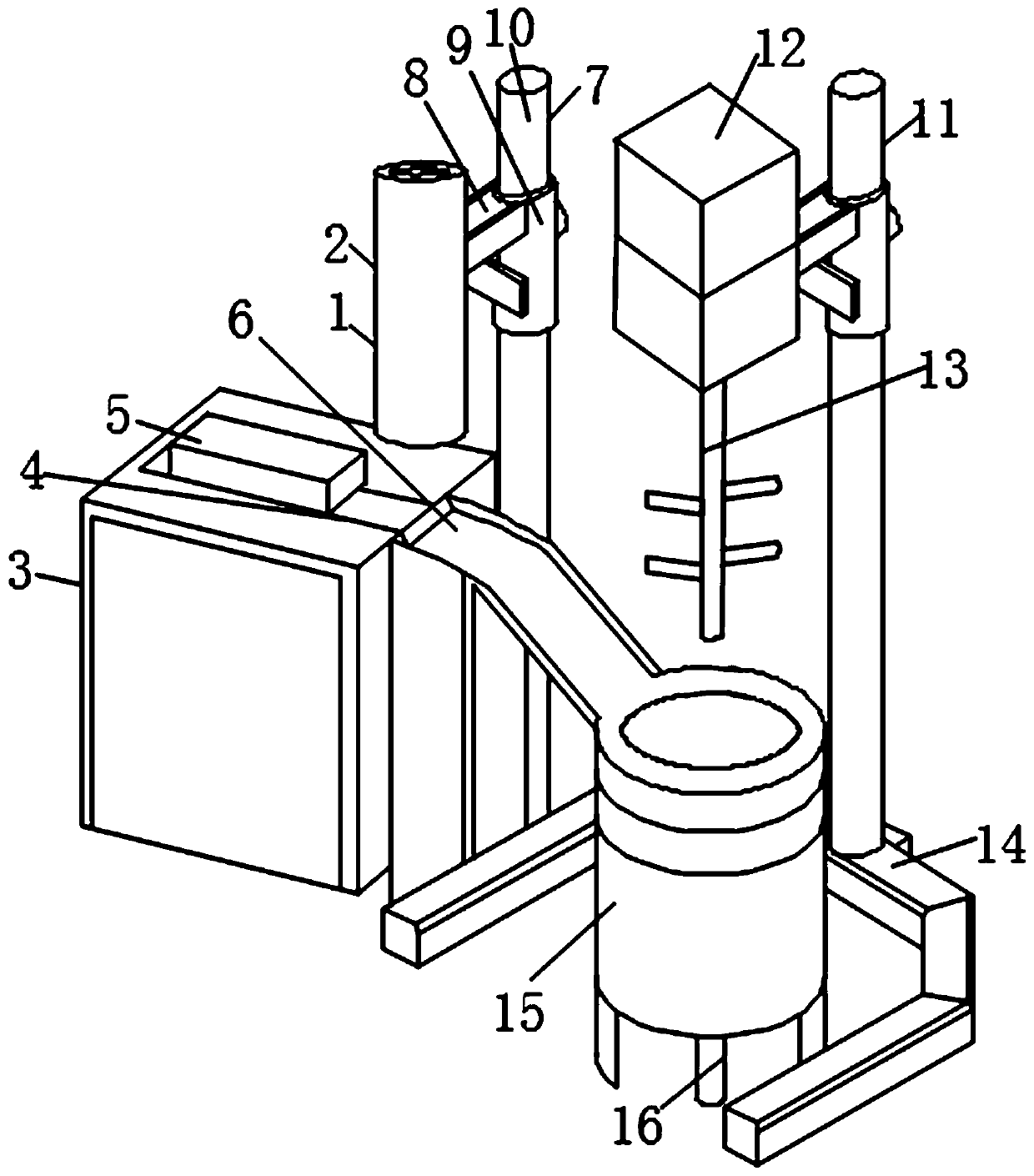

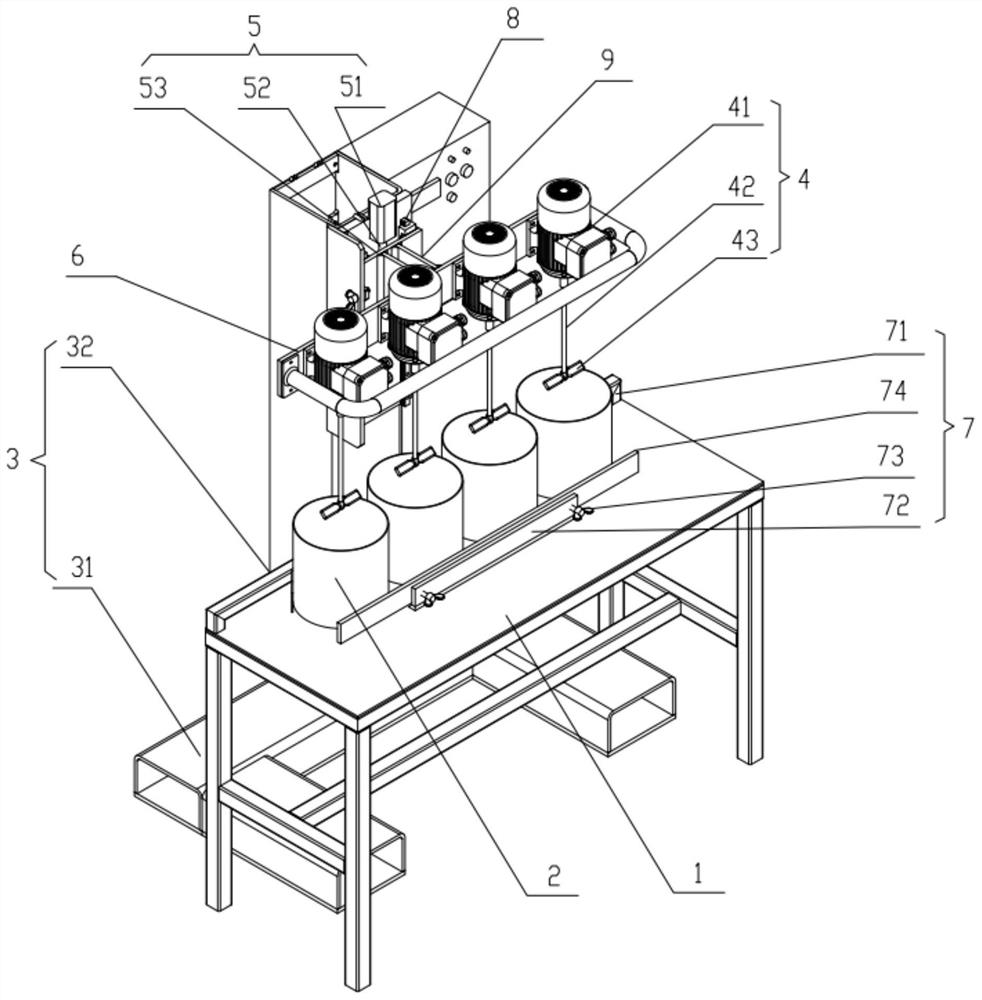

Batch-type uniform-speed discharging stirring device and construction method for self-leveling terrace

ActiveCN110453900ALift up movementEvenly mixedCement mixing apparatusFlooringElectric machineryEngineering

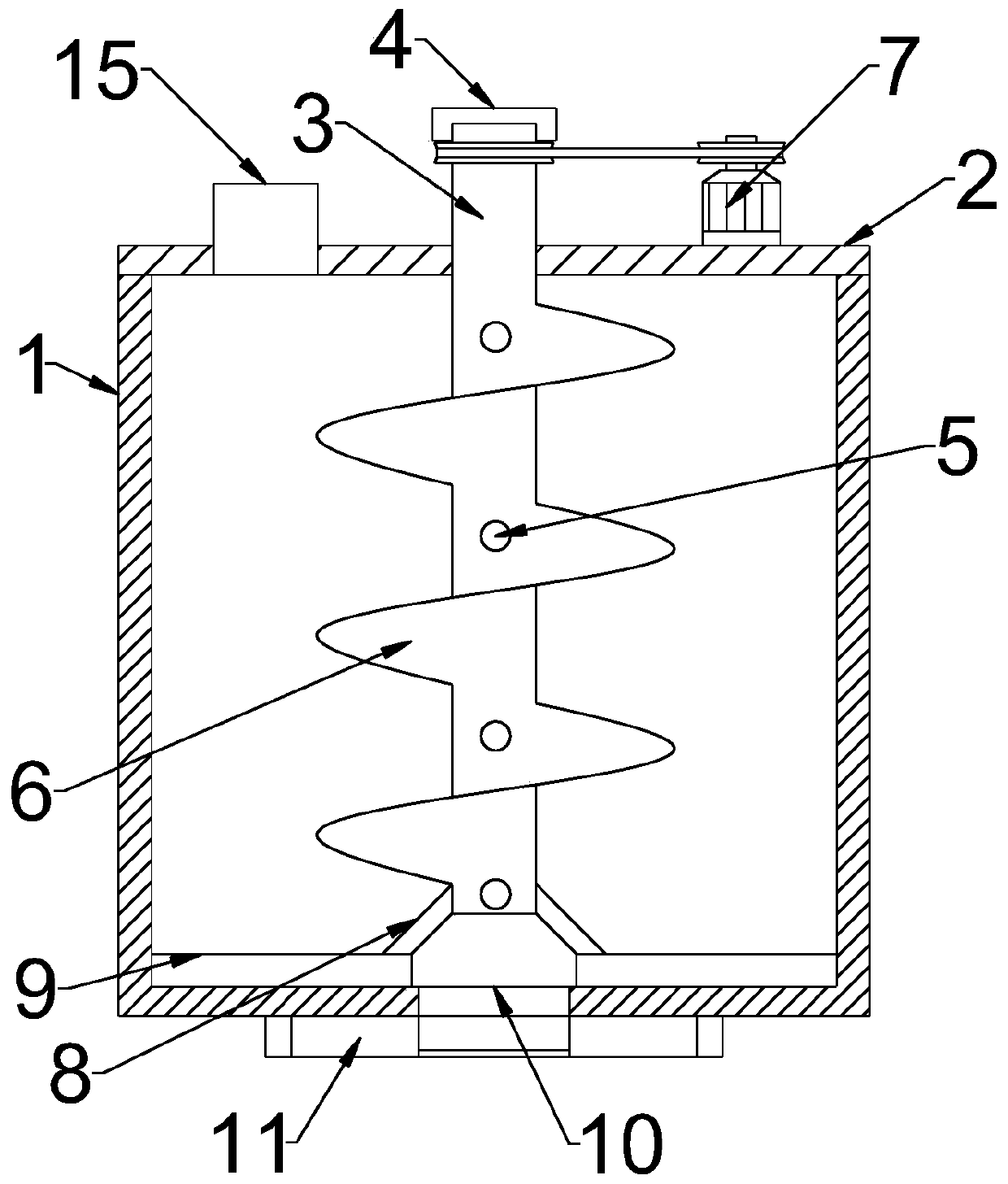

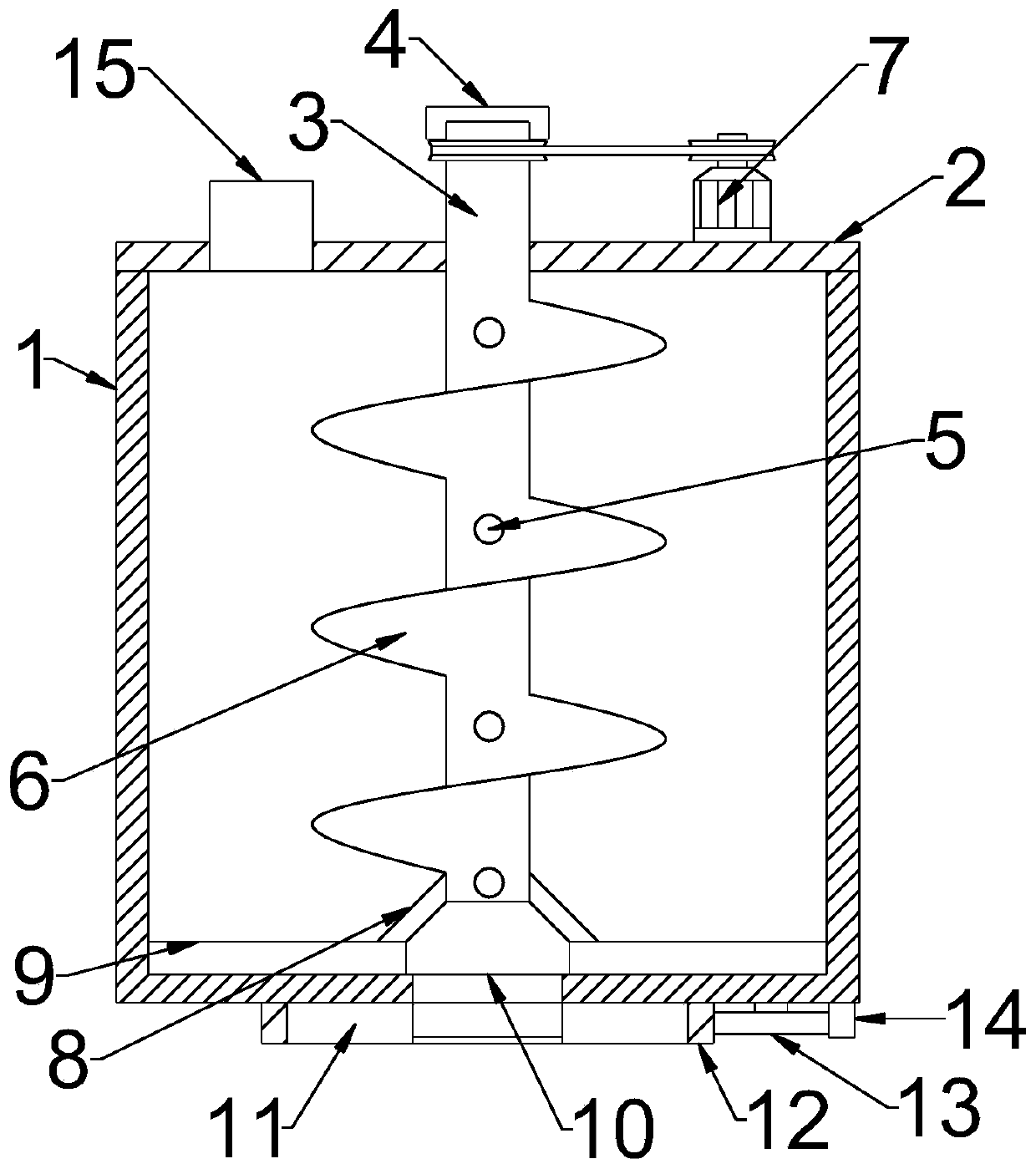

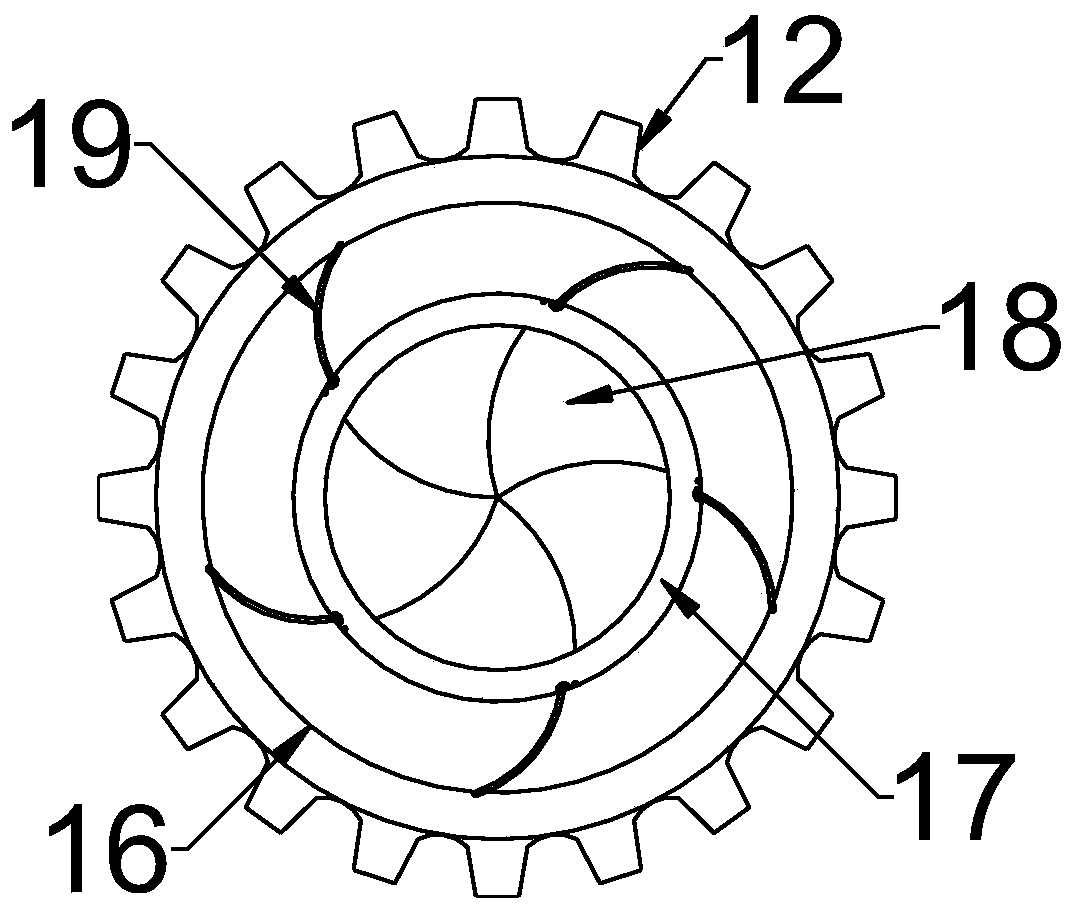

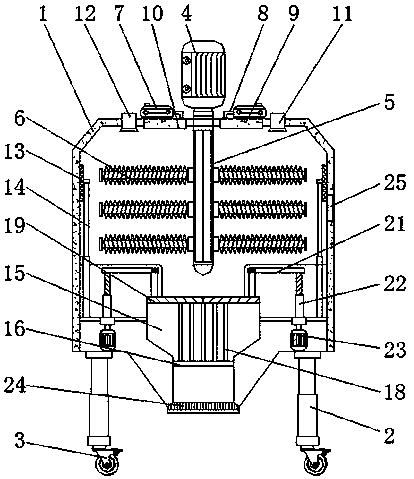

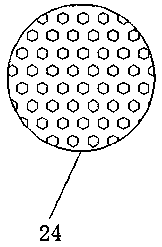

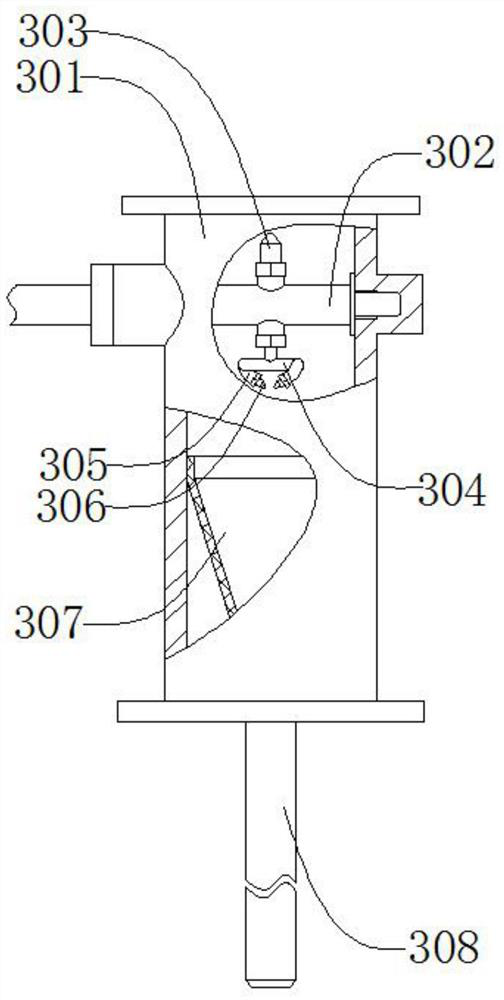

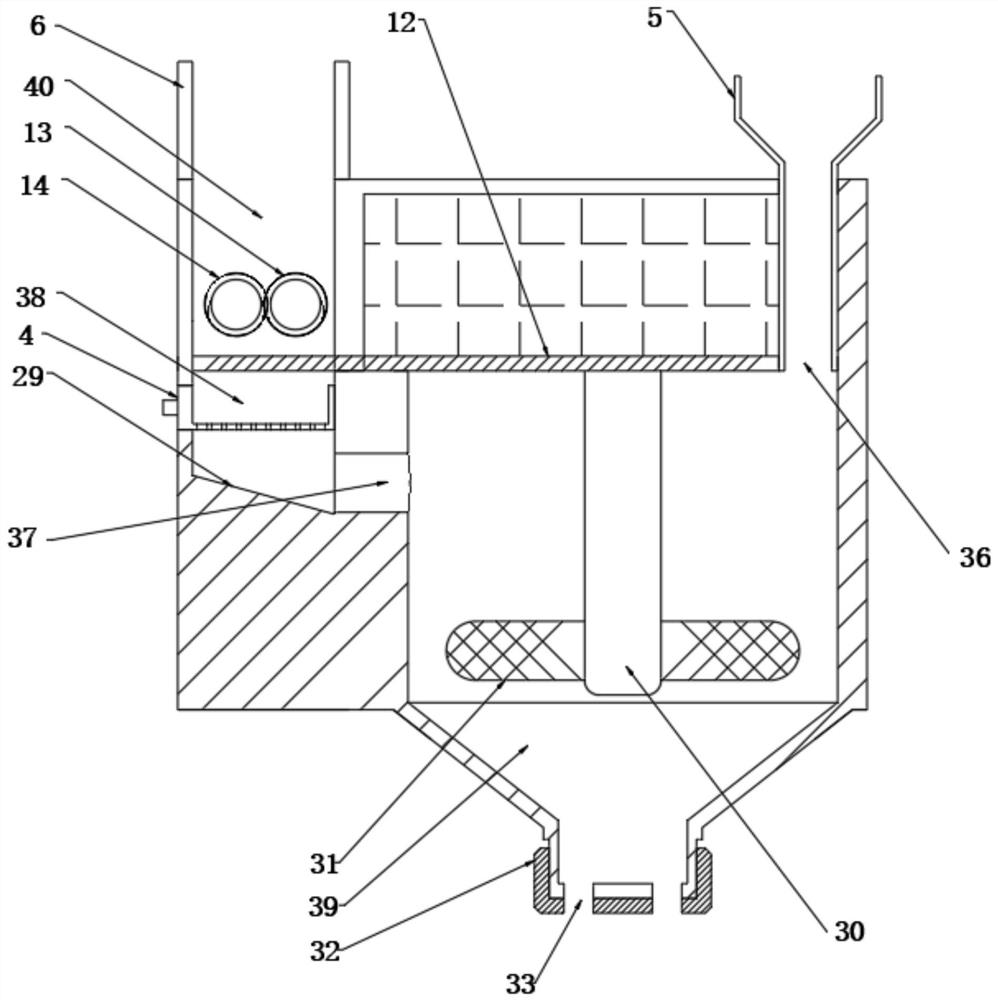

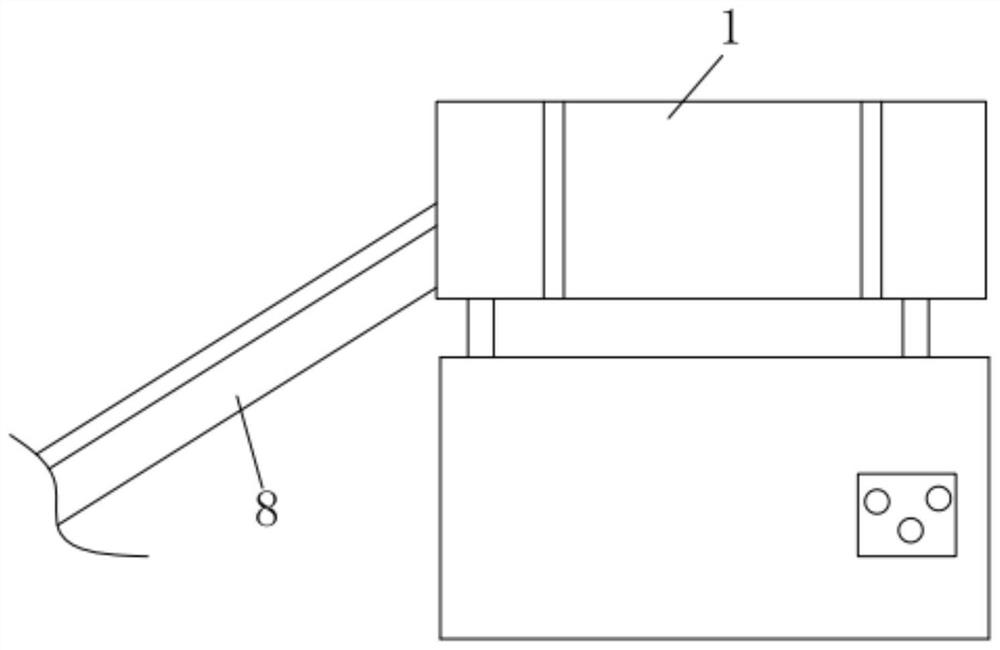

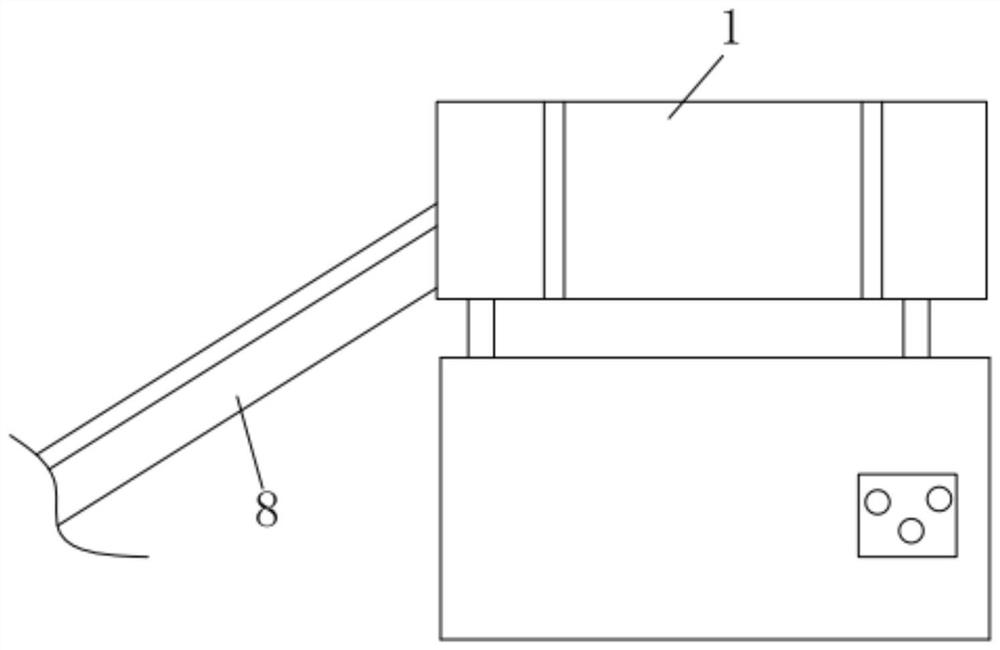

The invention discloses a batch-type uniform-speed discharging stirring device. The batch-type uniform-speed discharging stirring device comprises a kettle structure formed by assembling of a shell and an upper cover, the upper cover is provided with a stirring mechanism in a connected mode, a discharging hole is formed in the lower end of the shell in a penetrating mode, the stirring mechanism iscomposed of spiral fan blades connected to the periphery of a rotating shaft and used for introducing additives, the upper end of the rotating shaft is connected with a motor in a transmission mode,and a discharging mechanism opened in a mechanical and batch-type mode is further arranged at the lower end, of the periphery of the discharging hole, of the shell in a connected mode. A constructionmethod of a self-leveling terrace comprises the following steps that a base layer is checked, pulling-drawing detecting is conducted, and the base layer is cleaned; grinding, leveling by pushing and dust suction treatment are conducted; repairing treatment is conducted on gaps and hollowing parts; coating and painting of an interfacial agent are conducted, and line snapping and area division are conducted; mixed slurry is machined by using the device, and pumping construction is conducted after testing; and still standing and solidification, coating and painting of a protective agent, divisiondismantling and filling of joint mixture are conducted. The batch-type uniform-speed discharging stirring device can be matched with division-type construction to realize equal-amount batch-type material injection, and thus the structure problem of large-area construction is solved.

Owner:福建磊鑫(集团)有限公司

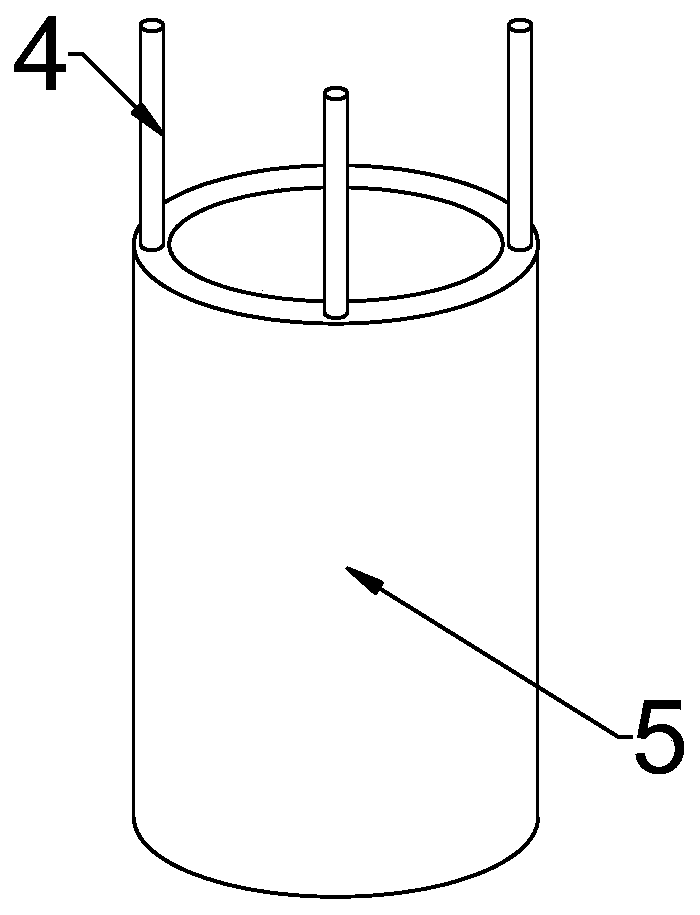

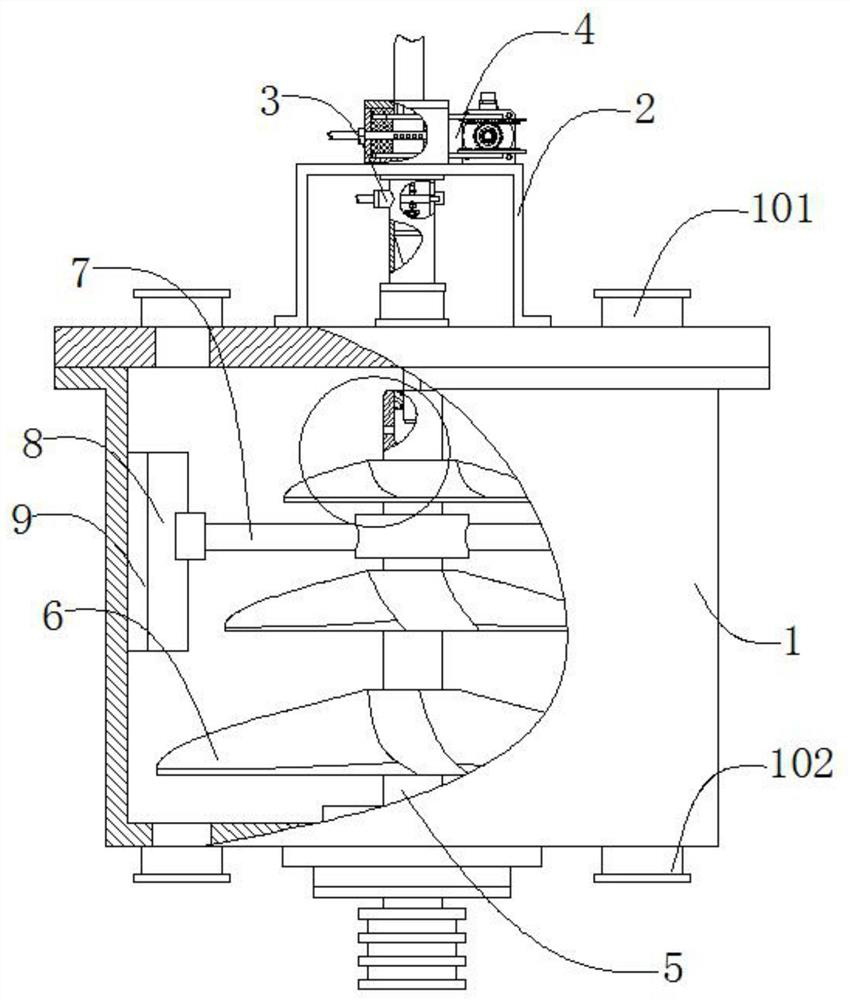

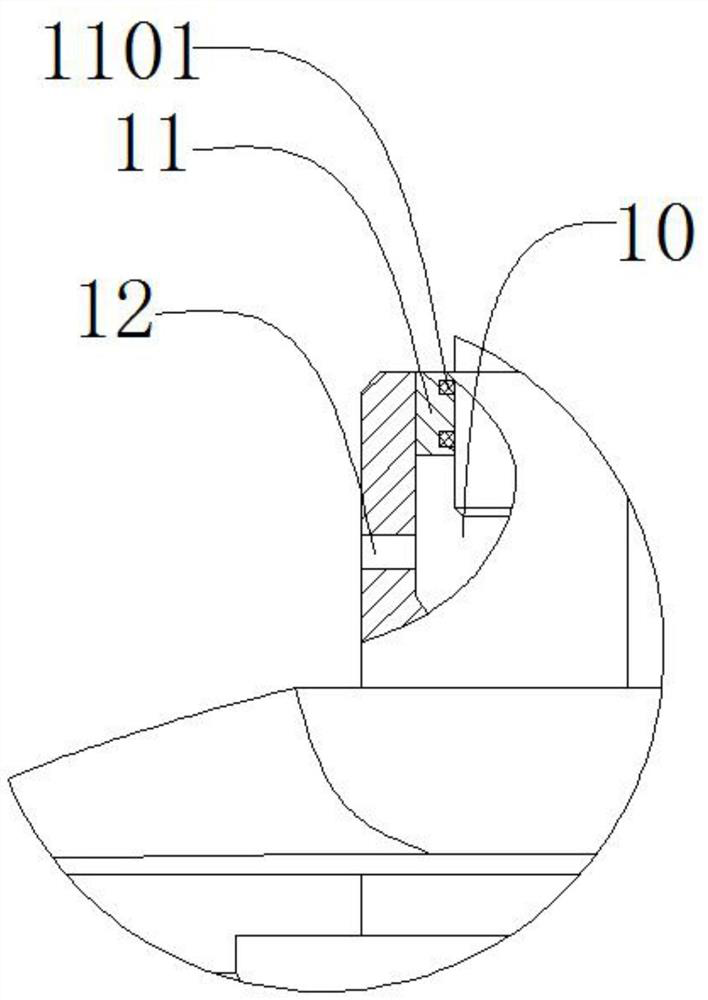

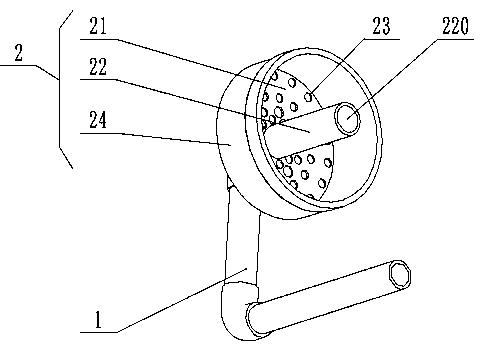

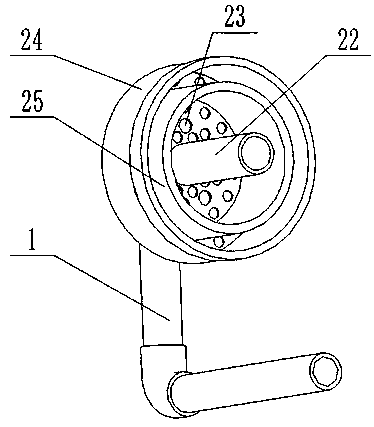

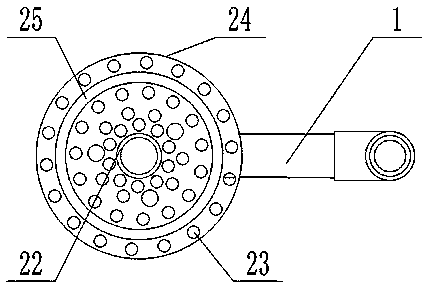

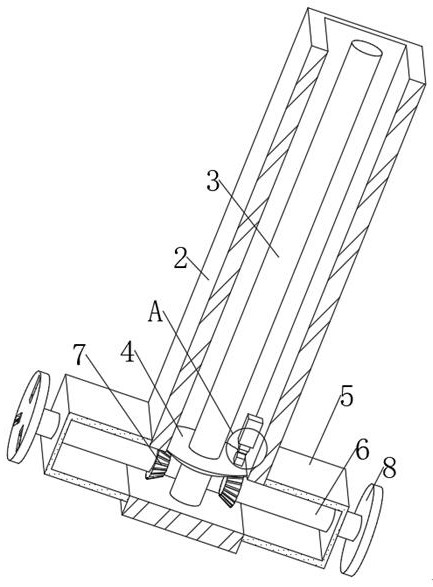

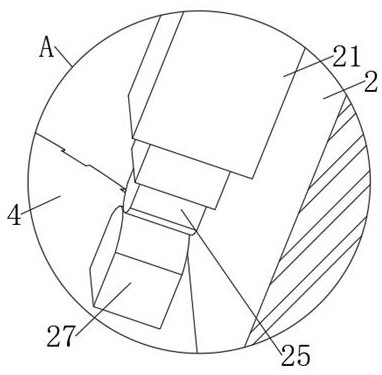

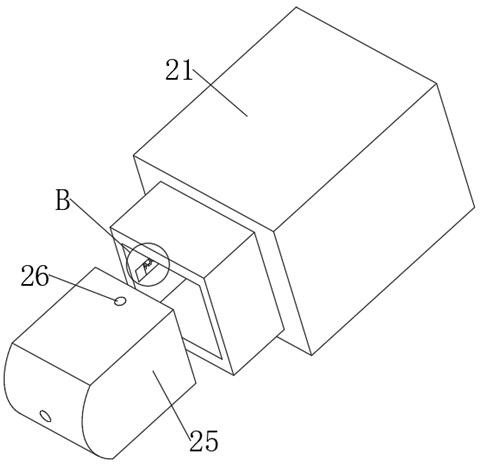

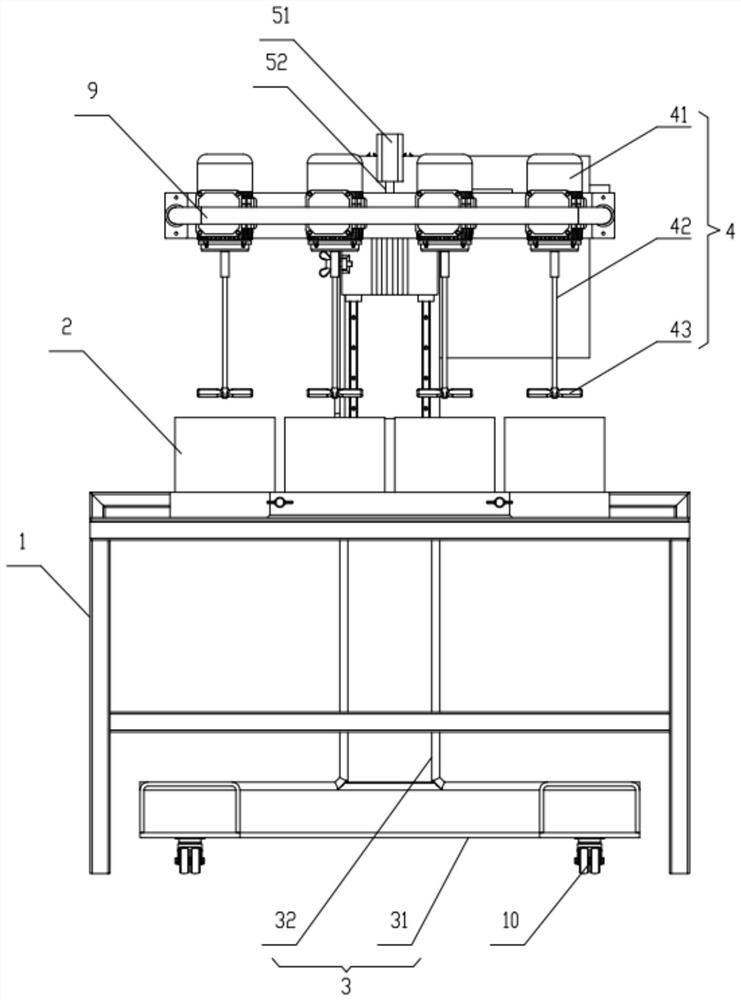

Three-dimensional stirring equipment for diamond powder

PendingCN112076658AMix evenly and efficientlyControl the stirring timeRotating receptacle mixersShaking/oscillating/vibrating mixersCrankElectric machine

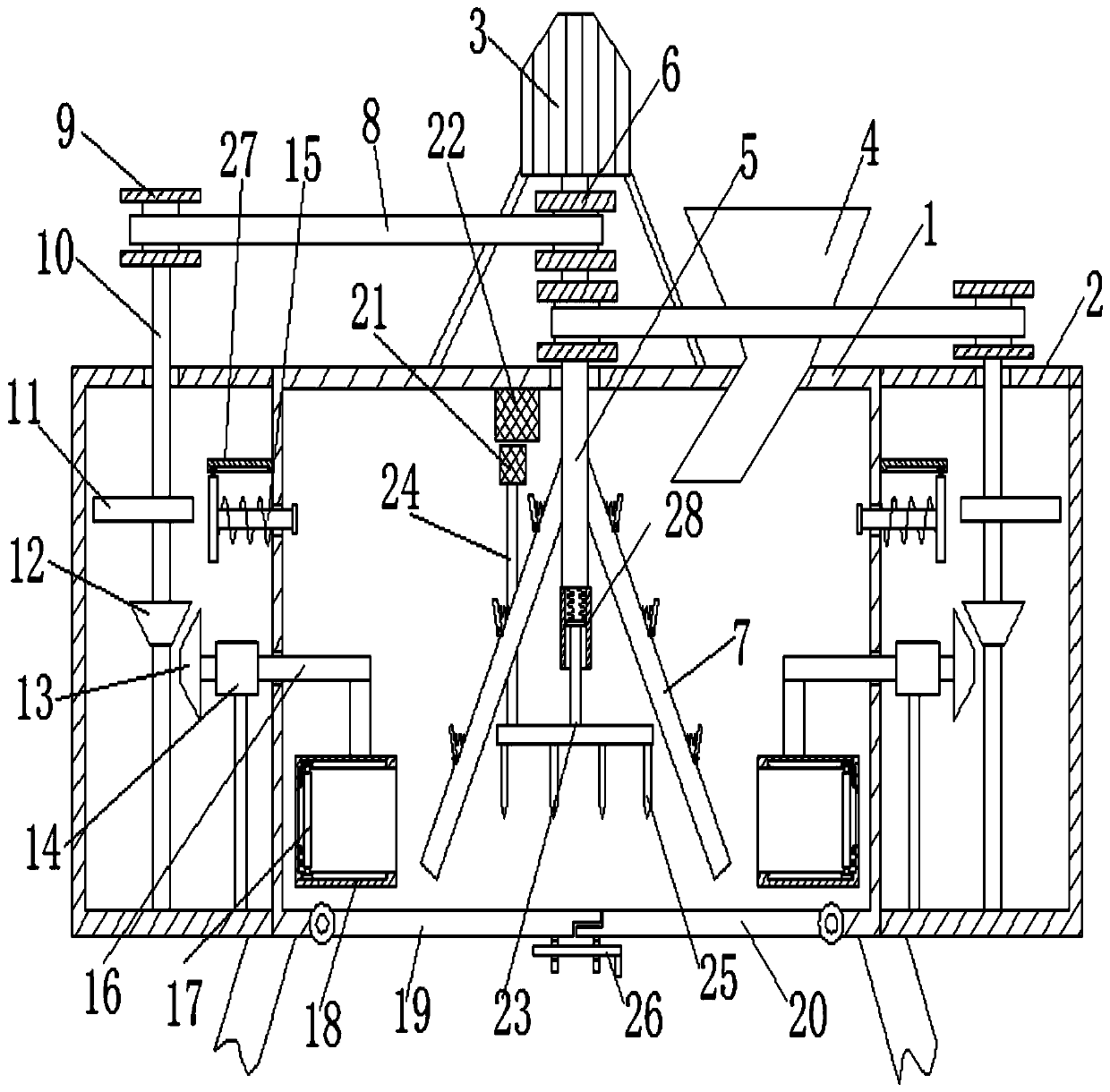

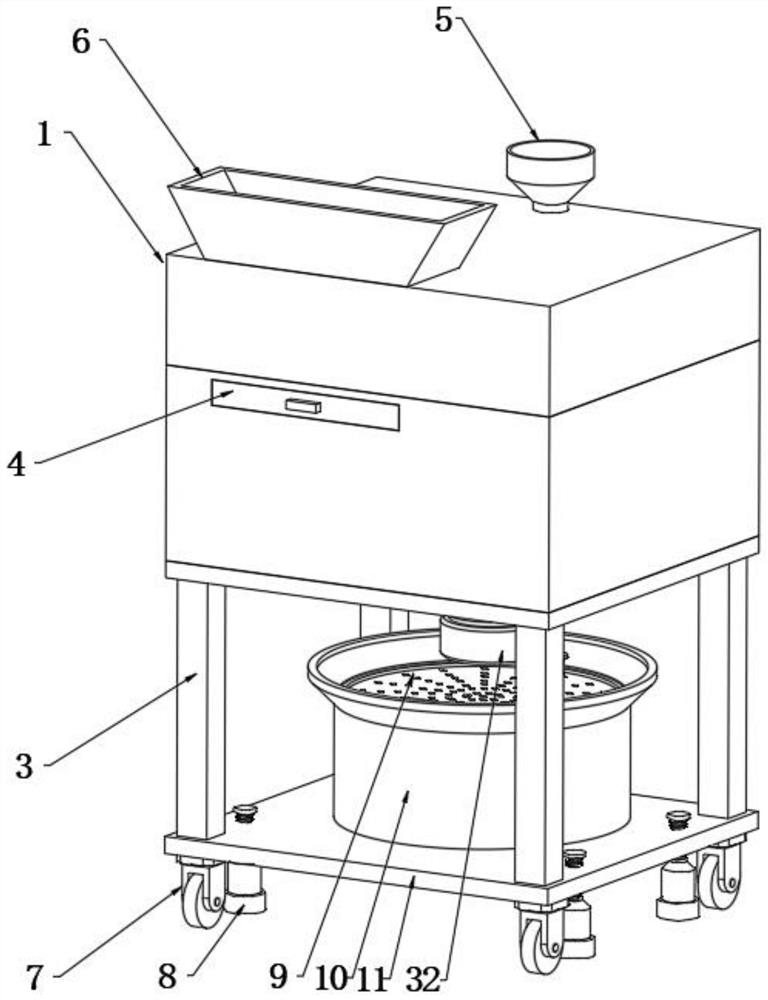

The invention discloses three-dimensional stirring equipment for diamond powder in the technical field of stirring equipment. The equipment mainly comprises a rack cabinet body, motor supporting seatsare symmetrically arranged on the left side and the right side of the top of the rack cabinet body, and rotary speed reducing motors are respectively arranged on the outer sides of the motor supporting seats on the two sides; a crank rotating rod is vertically connected to the output end of the inner side of each rotary speed reducing motor, a translation movable rotating shaft is inserted into the tail end of each crank rotating rod in a sliding mode, a stirring cylinder is fixedly arranged between the movable rotating shafts on the two sides, and stirring mechanisms are arranged on the leftside and the right side of an inner cavity of the stirring cylinder in a staggered mode; a material access hole is formed in one side of the outer wall of the stirring cylinder; a sampling device isarranged on the other side of the outer wall of the stirring cylinder, a translation guide rail surrounding in the circumferential direction is arranged on the outer wall of the stirring cylinder, a guide rail limiting seat matched with the translation guide rail is fixedly arranged at the top of the rack cabinet body, and a discharging groove is formed in the center of the top of the rack cabinetbody. The invention provides the three-dimensional stirring equipment for the diamond powder, so that materials are stirred and mixed more efficiently and uniformly.

Owner:南安市鄂丰机械有限公司

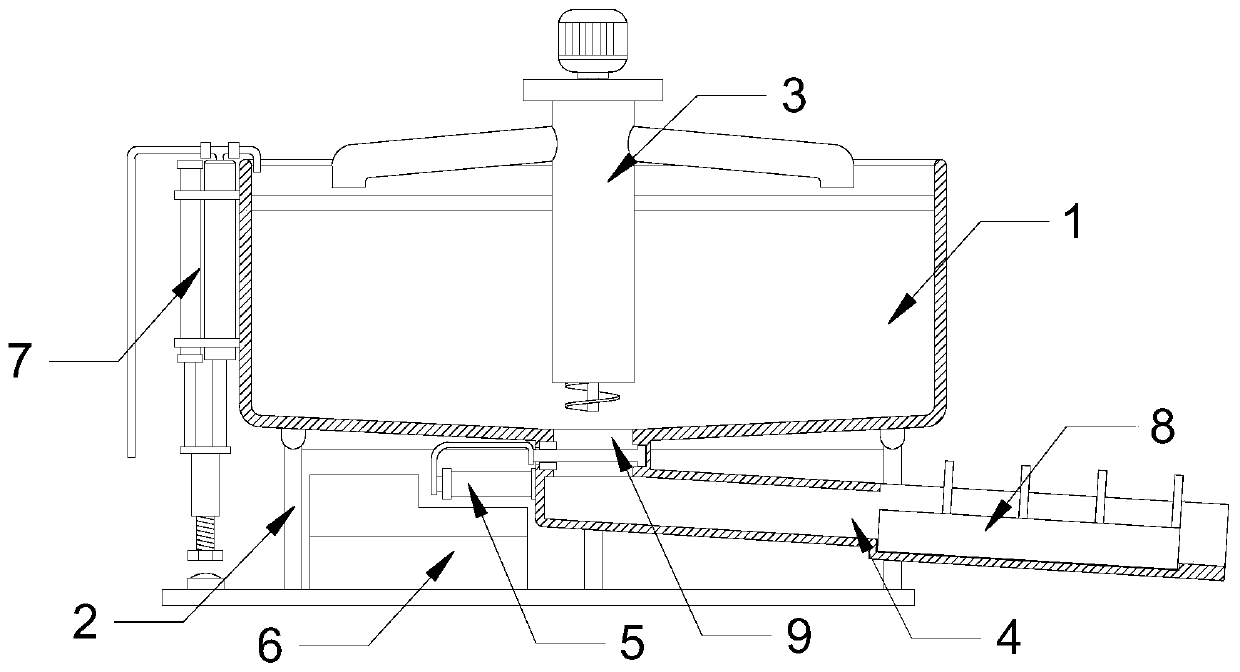

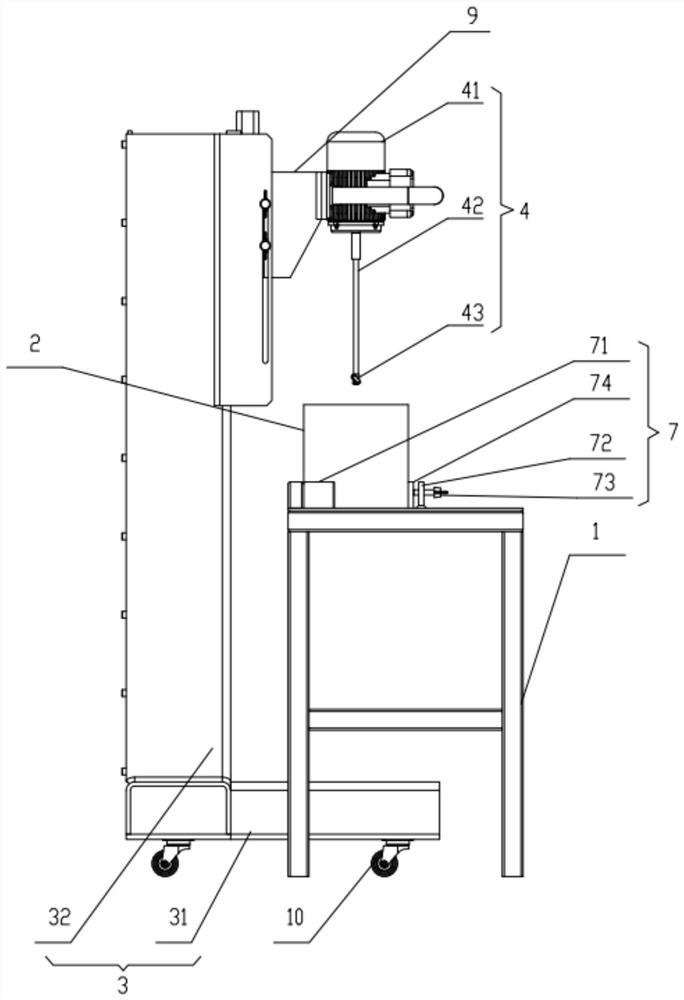

Efficient mixing and detecting integrated device for self-compacting concrete workability

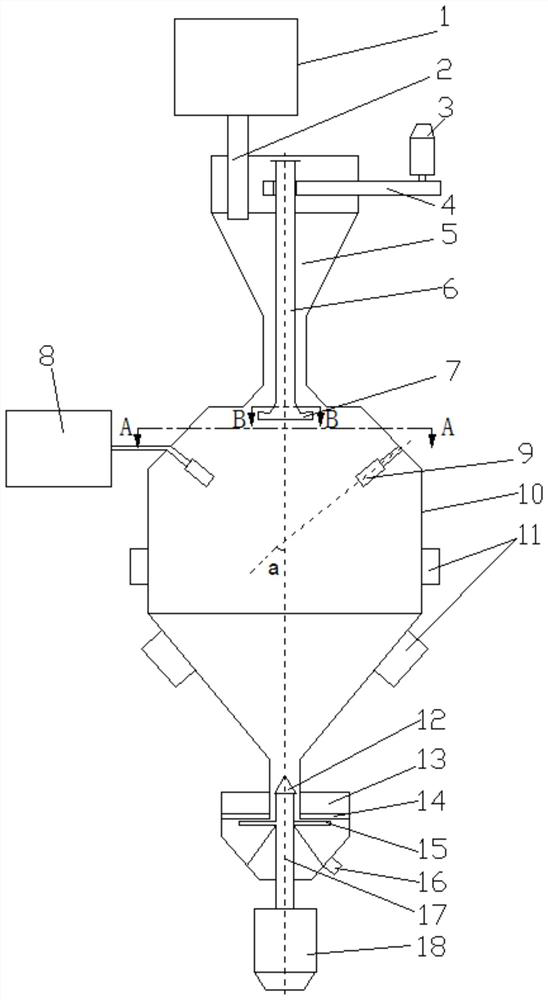

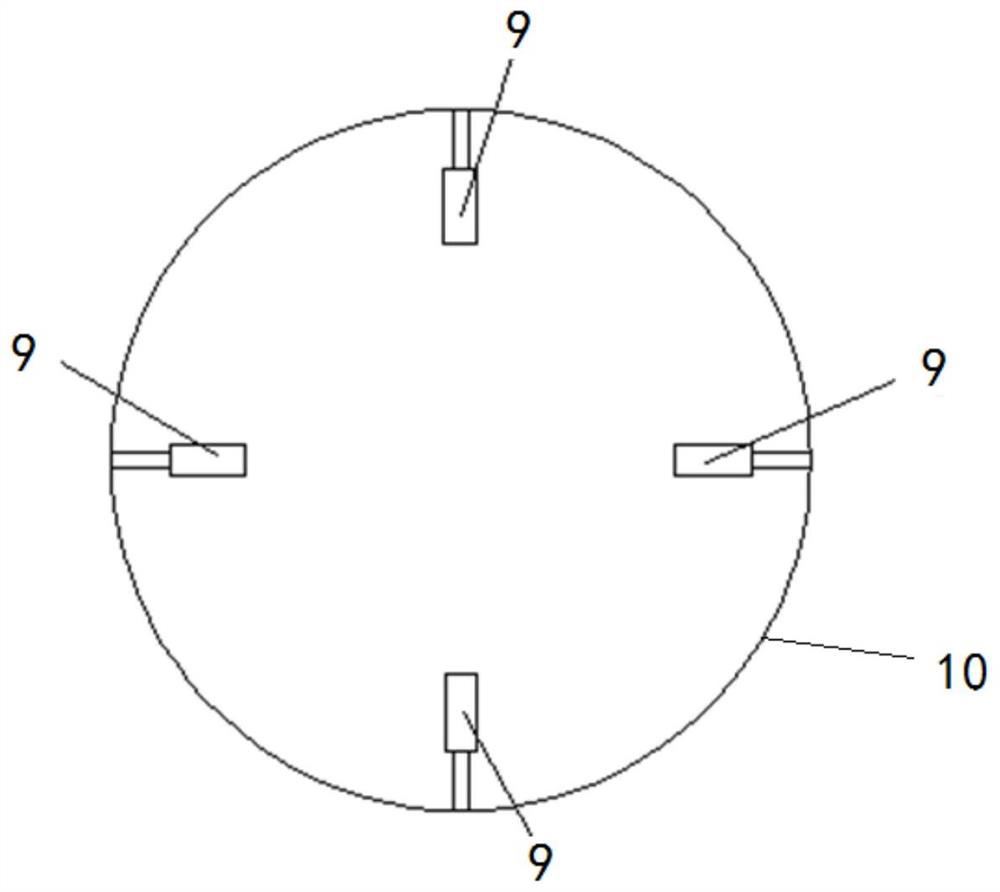

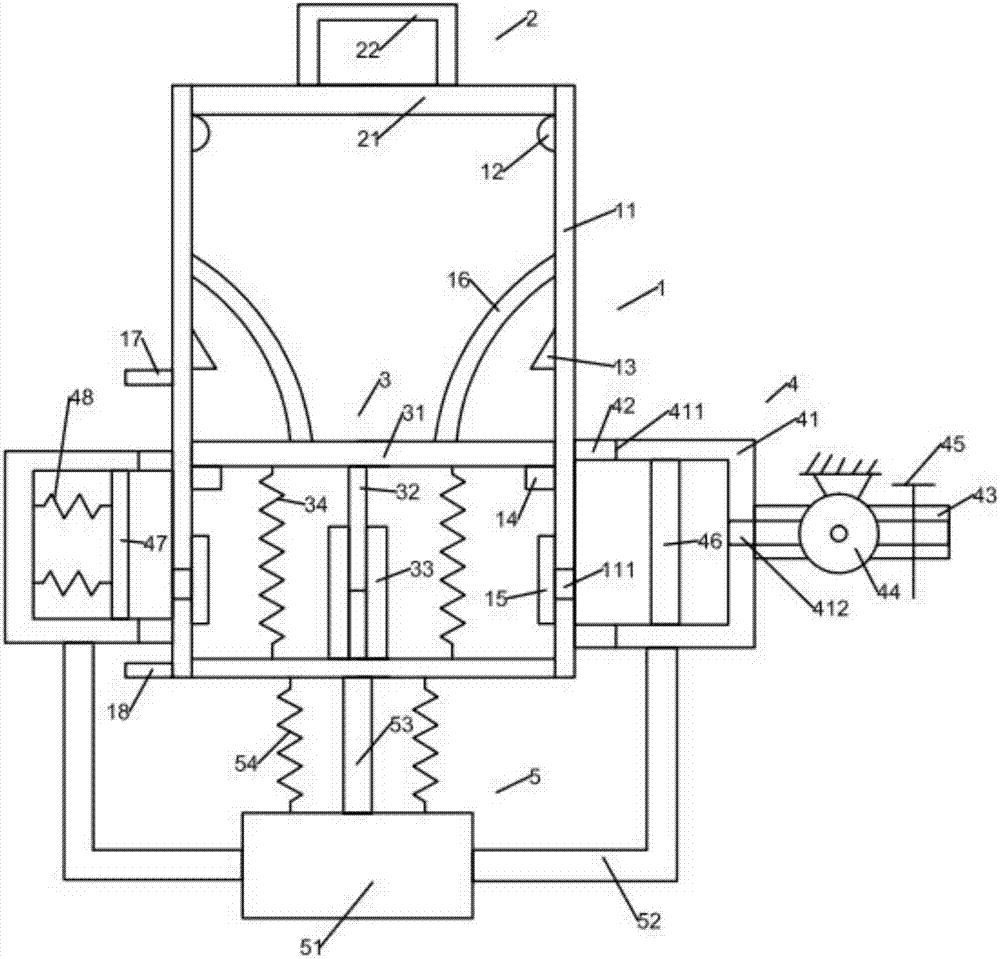

InactiveCN110328755AMix evenly and efficientlyGuaranteed accuracyFlow propertiesWithdrawing sample devicesEngineeringFan blade

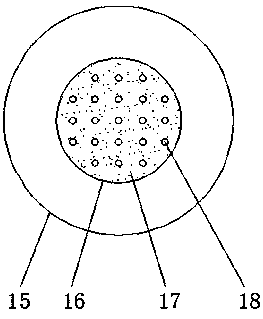

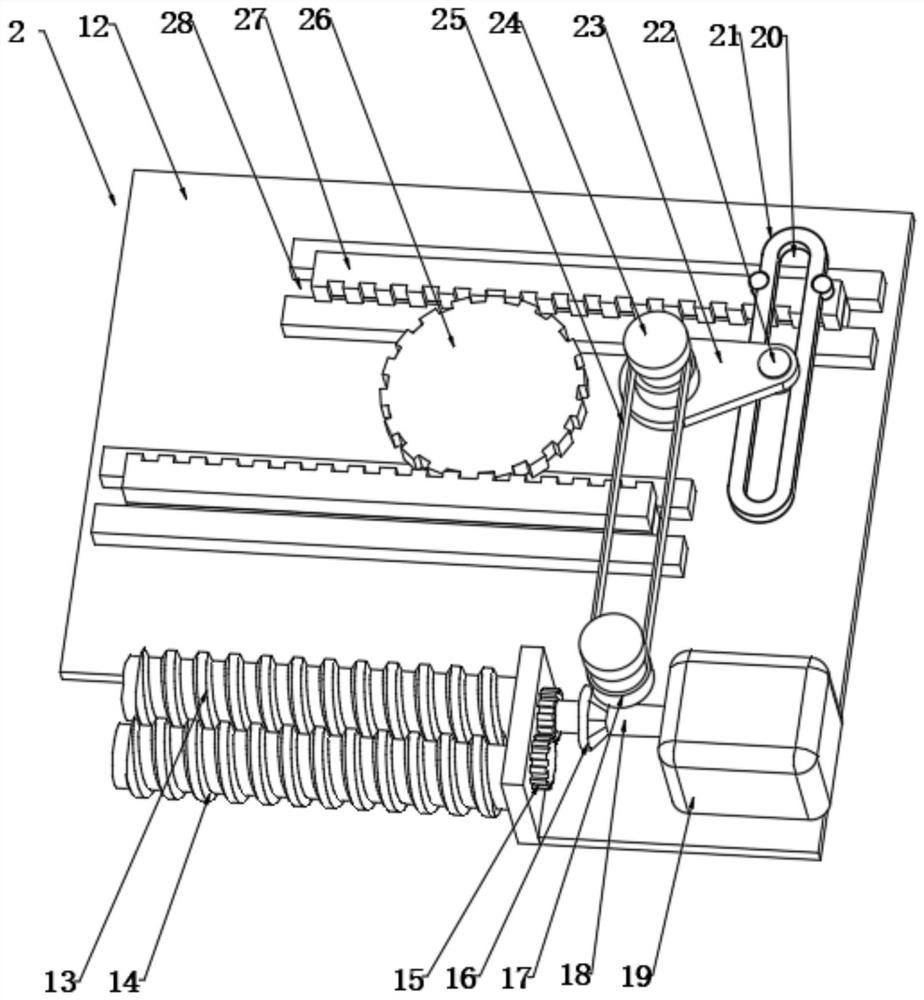

The invention discloses an efficient mixing and detecting integrated device for self-compacting concrete workability. The efficient mixing and detecting integrated device comprises a processing cavityand a L-shaped instrument, the upper end of the processing cavity is movably connected with an upper cover through a riveting mode, a feeding mechanism for conveying concrete from the processing cavity to the L-shaped instrument is arranged on the upper cover, a rotating sleeve is rotationally connected to the middle of the lower end of the processing cavity, and a rotating bottom plate and spiral fan blades are connected to the rotating sleeve, the rotating sleeve drives the rotating bottom plate to rotate forwards and backwards through the driving of a rotating mechanism, and the rotating sleeve drives the spiral fan blades to carry out unidirectional intermittent rotation. According to the efficient mixing and detecting integrated device, concretes are uniformly mixed under the liftingcondition of the spiral fan blades, stirring edges drive the materials at the bottom inside the processing cavity to be matched with the whole lifting circulation to realize further mixing, so that the materials can be efficiently and uniformly mixed, when the materials are required, after a slurry pump is started, the self-compacting concrete in the processing cavity is pumped out and injected into the L-shaped instrument for detection, so that the accuracy of monitoring can be ensured.

Owner:张波

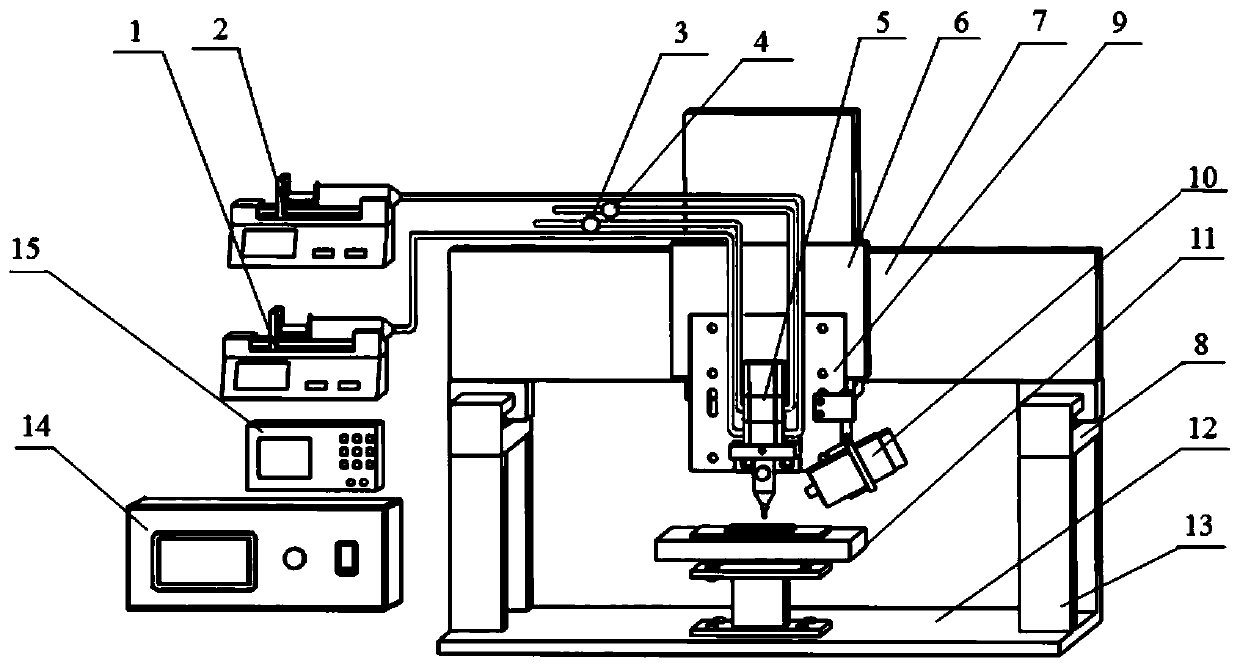

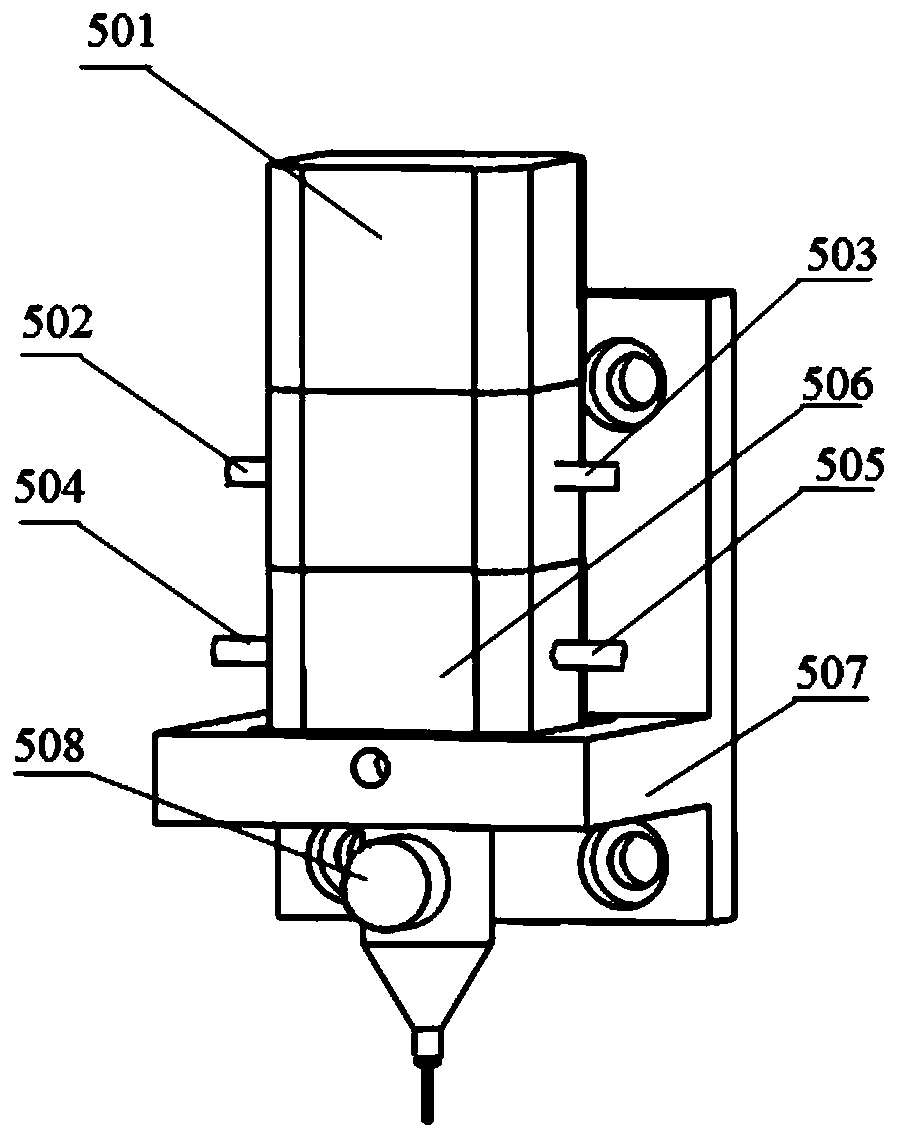

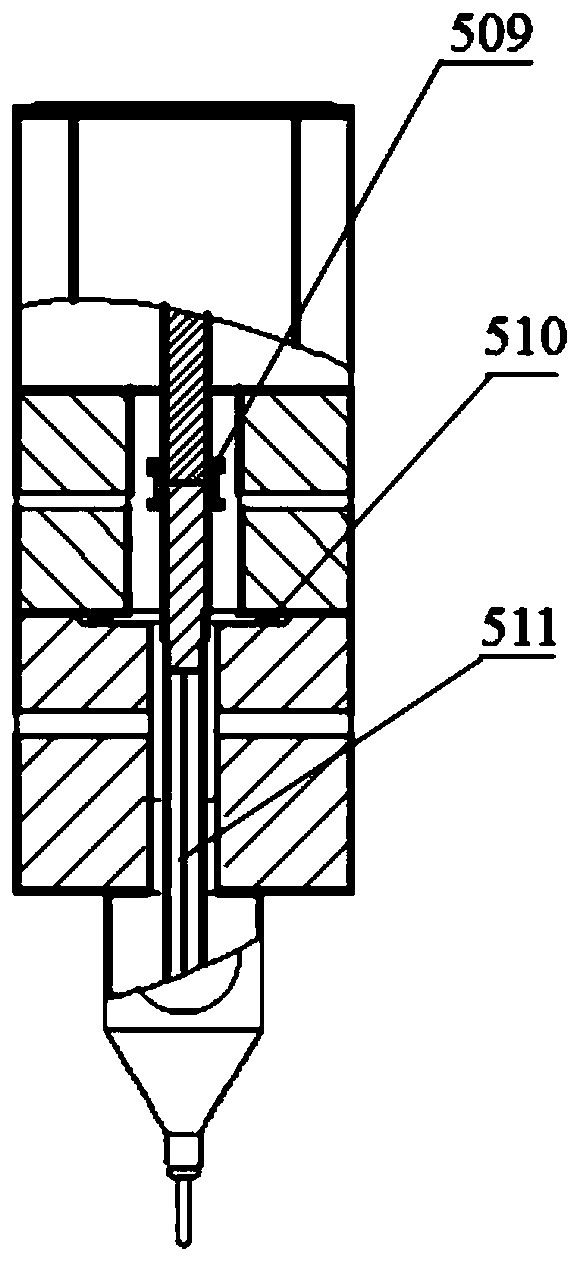

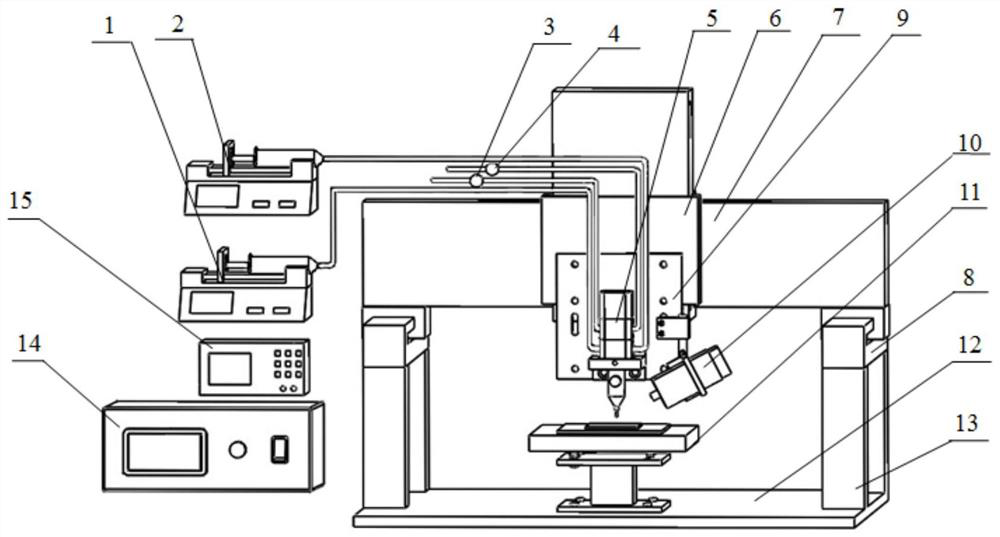

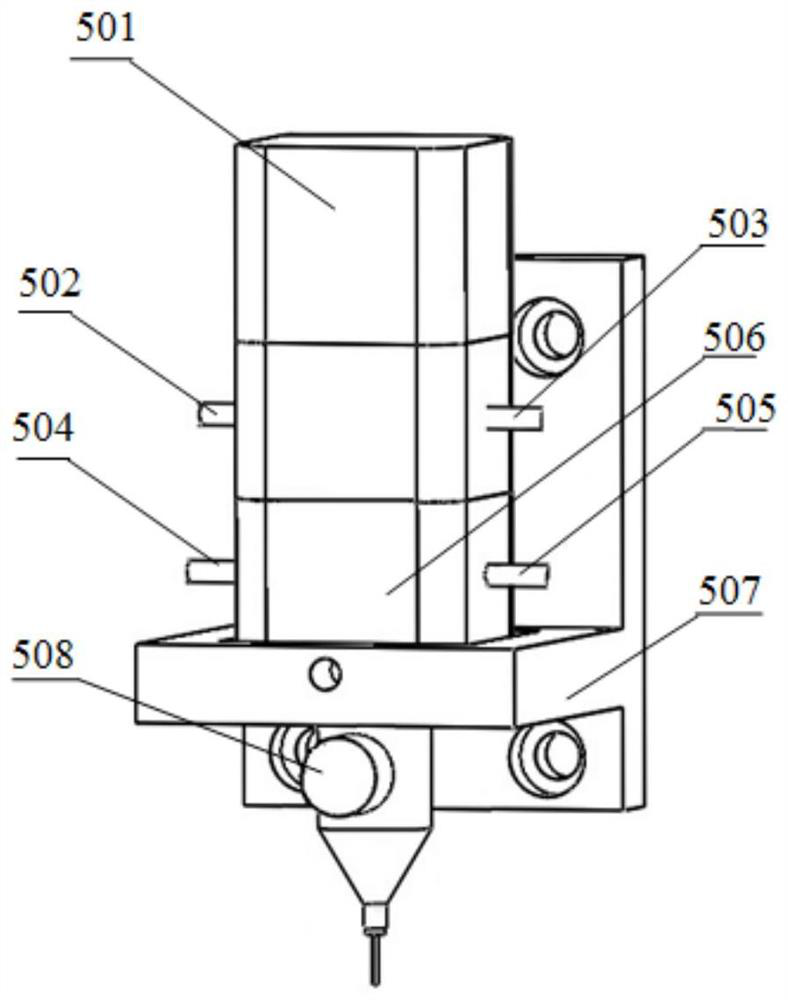

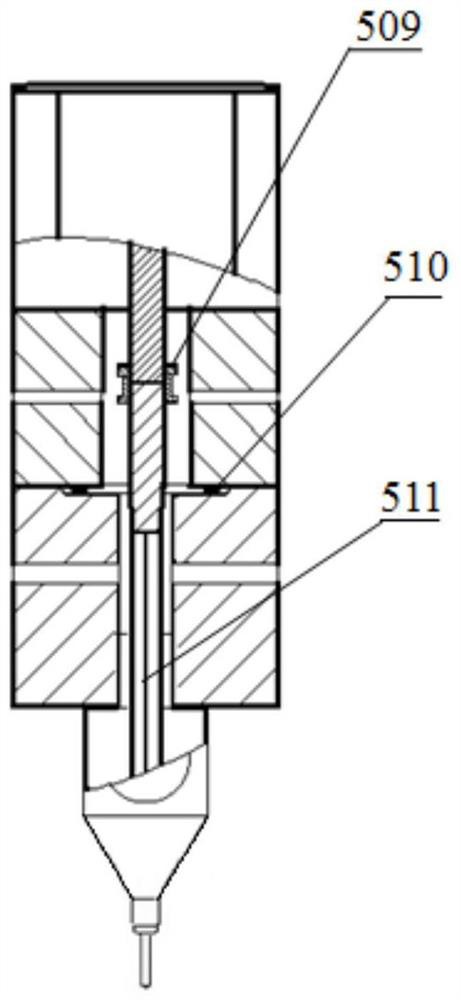

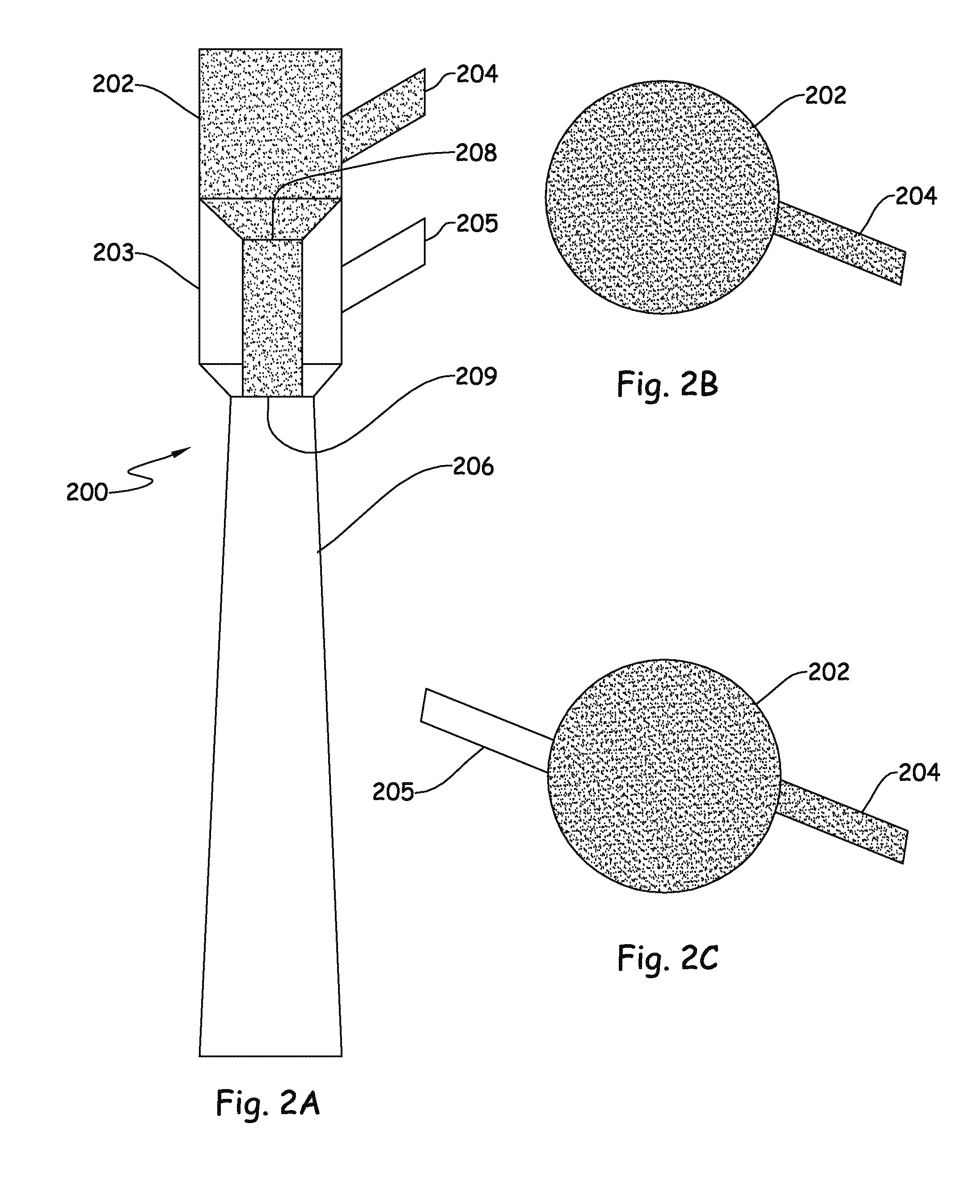

Function gradient material and structure integrated manufacturing 3D printing device and printing method

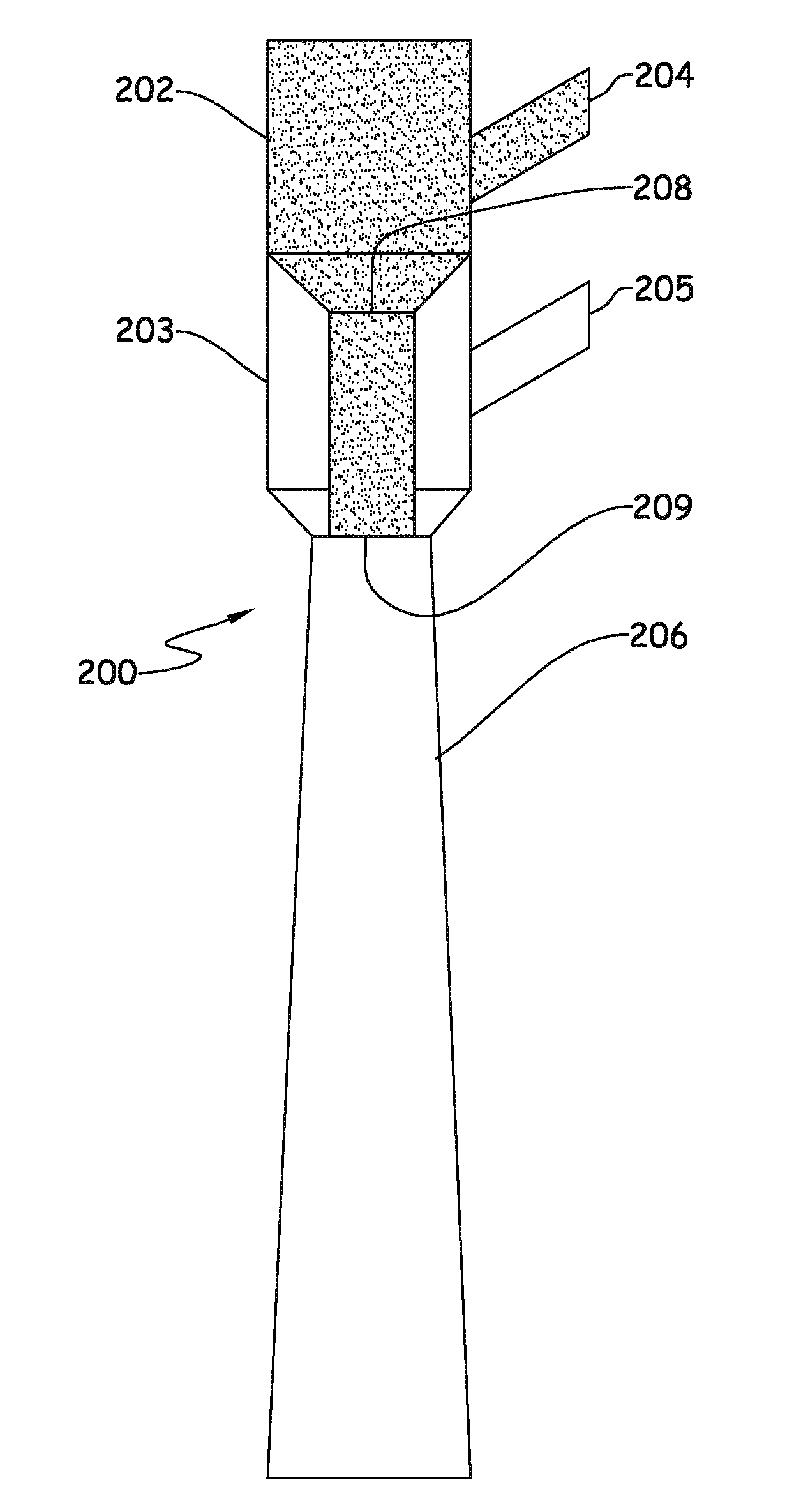

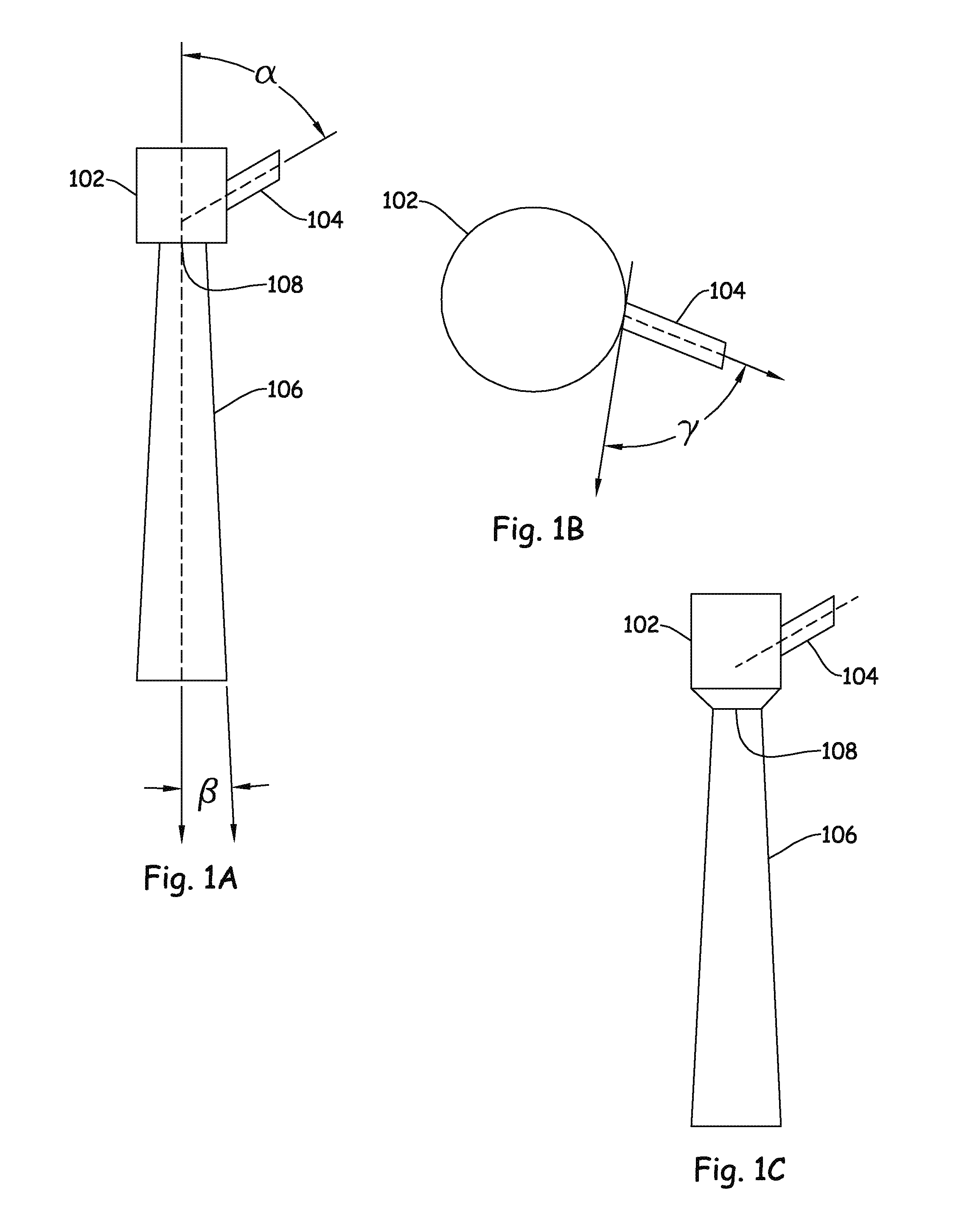

ActiveCN111284004AImprove the mixing effectAvoid mixing dead endsAdditive manufacturing apparatus3D object support structuresGradient materialSpray nozzle

The invention discloses a function gradient material and structure integrated manufacturing 3D printing device and printing method. The 3D printing device comprises a three-dimensional moving supportand a printing nozzle mounted on the three-dimensional moving support and including a stepping motor, a stirring paddle, a shell and a spray nozzle, the stepping motor is mounted at the end of the shell, one end of the stirring paddle is connected with an output shaft of the stepping motor through a coupling, the other end of the stirring paddle extends into a mixing chamber in the shell, the output shaft of the stepping motor and the shell are sealed, the spray nozzle and the stepping motor are oppositely mounted at the other end of the shell, the position, between the nozzle and the mixing chamber, of a material runner is provided with a control valve, a printing material I inlet and a printing material II inlet are formed in the side wall of the mixing chamber and are connected with a printing material I supply pump and a printing material II supply pump correspondingly, and a gas path I opening and a gas path II opening are formed in the position, between the mixing chamber and thestepping motor, of the side wall of the shell, and are connected with a gas source and a vacuum pump.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Textile size mixing device with self-cleaning function

InactiveCN107754683AMix evenly and efficientlyImprove cleanlinessRotary stirring mixersTransportation and packagingEngineeringSupport plane

The invention discloses a textile size mixing device with a self-cleaning function. The textile size mixing device comprises a mixing box, a discharge channel and a pressing plate, wherein a support frame is arranged at the bottom end of the mixing box; a first motor is fixed at the center at the upper end of the mixing box; water pumps are fixed on the left and right sides of the first motor; a raw stock inlet and a color paste inlet are respectively formed in two sides of the upper surface of the mixing box; the discharge channel is positioned just under a rotating shaft; a groove is formedinside a partition plate; the pressing plate is positioned on the upper surface of the discharge channel; a hole is formed inside the pressing plate; the pressing plate is fixed at the top end of a second telescopic rod by virtue of a fixing rack; the bottom end of the second telescopic rod is mutually connected with the output end of a second motor; a discharge hole is formed in the bottom end ofthe discharge channel; and an observation window is formed in the outer surface of the mixing box. The textile size mixing device with the self-cleaning function is high in mixing efficiency, uniformin mixing and convenient to clean, and the cleanliness inside the mixing barrel is ensured.

Owner:泰兴市金鳌机械制造有限公司

Stirring device for efficiently and uniformly mixing and stirring black pig feeds

InactiveCN107803128AEfficient mixingStir evenly and efficientlyShaking/oscillating/vibrating mixersFeeding-stuffEngineeringCentrifugal force

The invention discloses a stirring device for efficiently and uniformly mixing and stirring black pig feeds. The stirring device comprises a stirring box, device boxes and a motor, wherein a pluralityof brackets are fixedly connected to the bottom end of the stirring box; two symmetrically arranged device boxes are fixedly connected to the outer side wall of the stirring box; through the combination of a stirring rod, a material shoveling frame and a top cone, efficient and uniform mixing of different pig feeds is effectively realized, the time for feeding pigs by workers is saved, the working intensity of the workers is reduced, the stirring rod rotates to stir the feeds, vibrating blades shake under the action of a centrifugal force and a fourth spring, and the stirring effect of the stirring rod is enhanced; the material shoveling frame shovels accumulated materials at the edge of the stirring box into the stirring range of the stirring rod; and a T-shaped rod moves up and down, sothat the top cone breaks lumps in the feeds while rotating and stirring, and the omnibearing and efficient uniform mixing of the feeds is realized.

Owner:嵩县金佛坪农业科技有限公司

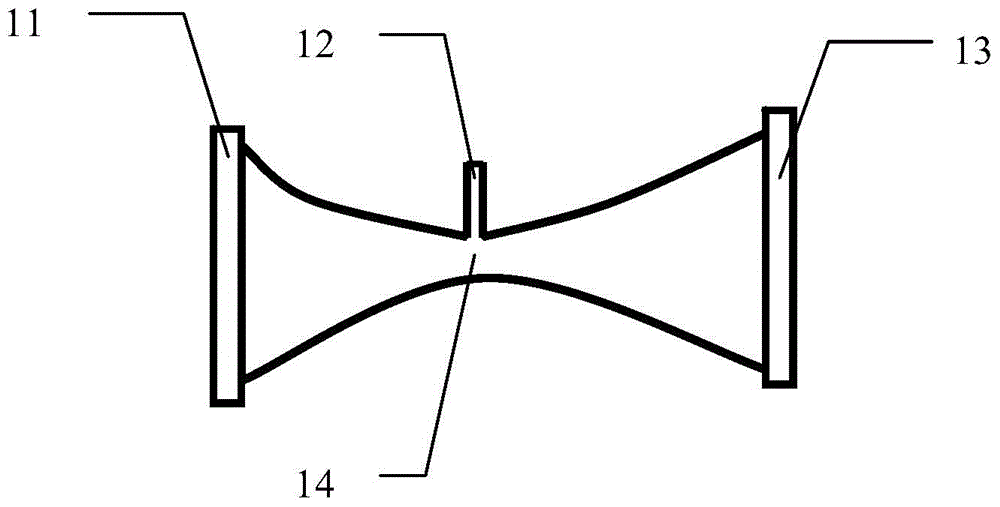

A general diluting method and a general diluting device

ActiveCN105642144AMix evenly and efficientlyFlow mixersPreparing sample for investigationHigh concentrationEngineering

The invention relates to a general diluting method and a general diluting device. The method includes extracting a dynamic fluid from a diluting fluid source through a power pump, adjusting the flow rate of the extracted dynamic fluid through a dynamic flow rate adjusting valve, filtering to remove impurities in the dynamic fluid through an efficient filter to form a clean fluid, injecting the clean fluid into a Venturi ejector through a dynamic inlet, allowing the clean fluid to flow through a part near a suction inlet of the Venturi ejector to form negative pressure in the suction inlet, allowing a fluid to be diluted to be inhaled through the suction inlet of the Venturi ejector, adjusting the flow rate of the fluid to be diluted which is inhaled from a source of the fluid to be diluted through a suction flow rate adjusting valve, allowing the fluid to be diluted and the clean fluid to be mixed efficiently in the Venturi ejector to obtain a mixed and diluted fluid, ejecting the mixed and diluted fluid from a dynamic outlet, feeding the mixed and diluted fluid from the dynamic outlet of the Venturi ejector to a buffer to release pressure, and sampling through a sampling port of the buffer. The method and the device can be widely applied in the fields of high-concentration fluid source monitoring, preparation of calibration fluids with given concentrations, dilution of expensive fluids, and the like.

Owner:北京汇丰隆生物科技发展有限公司

Agitation device for sweet potato powder processing

InactiveCN108654459APrevent adhesionReduce lossRotary stirring mixersTransportation and packagingWave shapeEngineering

The invention discloses an agitation device for sweet potato powder processing. The agitation device comprises an agitating barrel body, wherein a sealing cover is installed at the top end of the agitating barrel body, four corners of the bottom of the agitating barrel body are connected with support legs separately, the agitating barrel body is internally provided with a wave-shaped inner wall, aspray water pipe is sleeved with the top end of outer wall of the agitating barrel body, the spray water pipe is annular, a plurality of water nozzles are arranged on the inner wall of the spray water pipe at equal distance, water tanks are installed at the inner sides of the four support legs through support plates, and one end of the water tank is connected with a water pump through a pipeline.According to the wave-shaped inner wall provided by the invention, wet powder is prevented from attaching to the wave-shaped inner wall, thereby reducing resource waste, and maximizing use ratio of the resource; due to the annular spray water pipe and water nozzles, sweet potato powder and water are mixed uniformly, the work efficiency of the agitation device works is improved, the agitation period is shortened, the energy consumption of the agitation device is lowered, and the agitation device is more energy-saving and environmentally friendly.

Owner:临泉县森茂农业有限责任公司

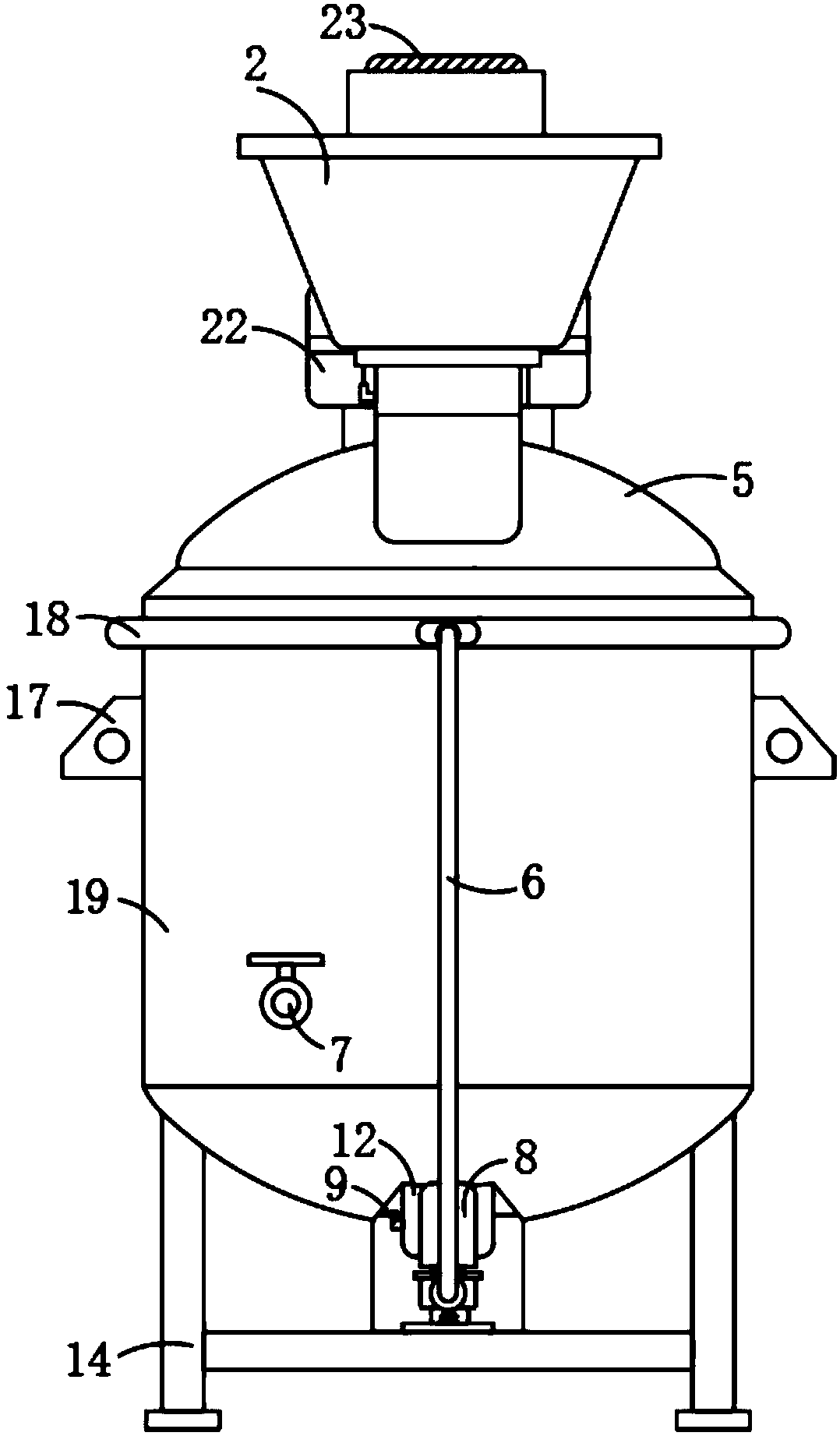

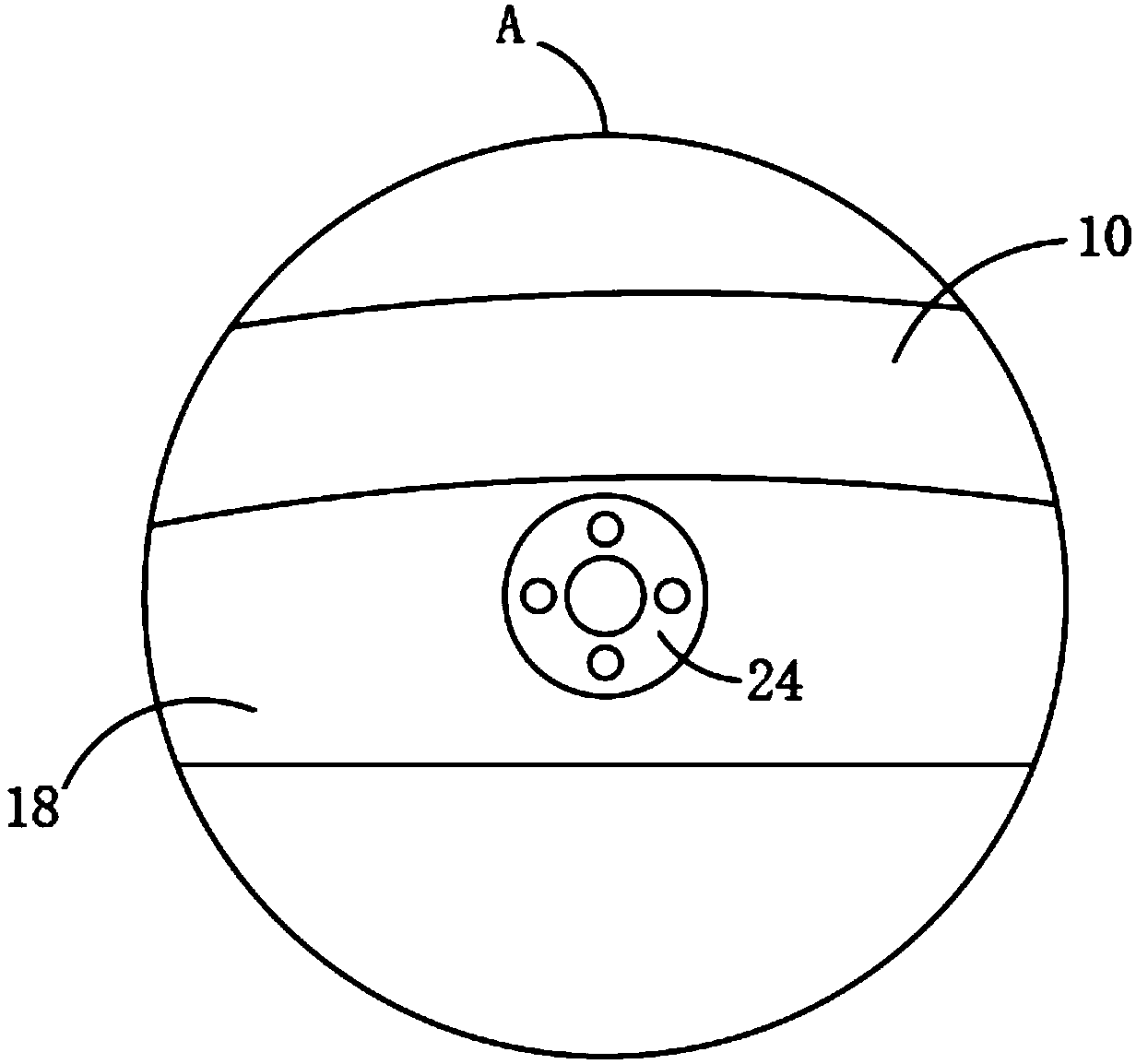

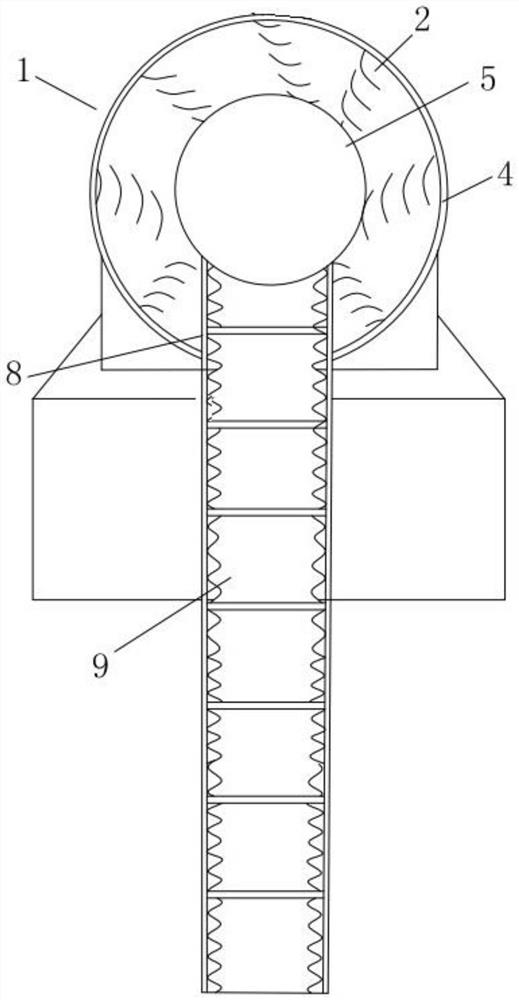

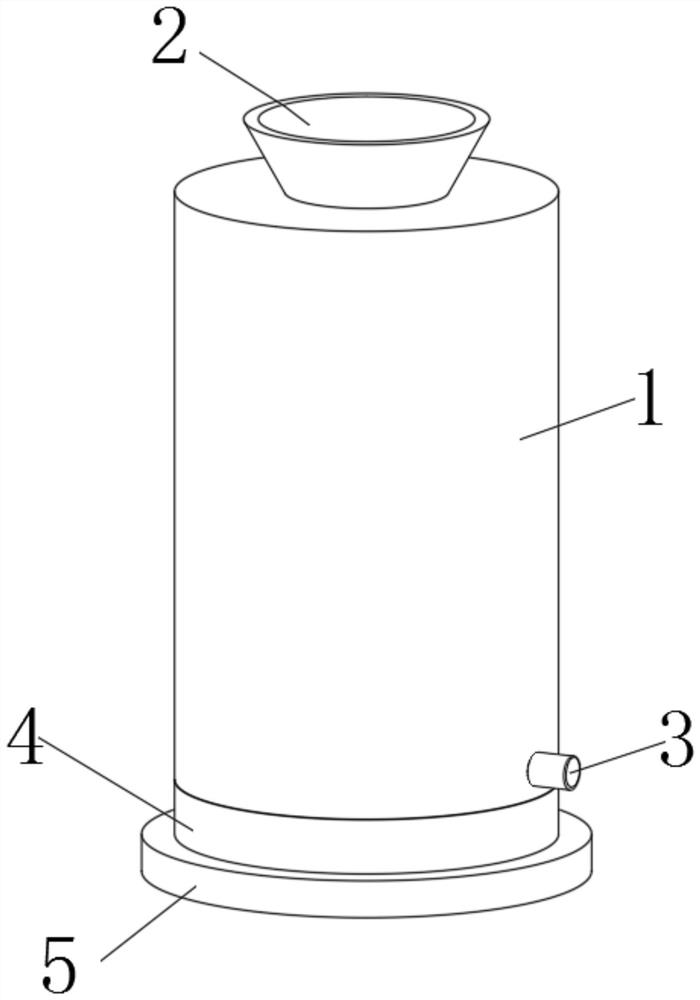

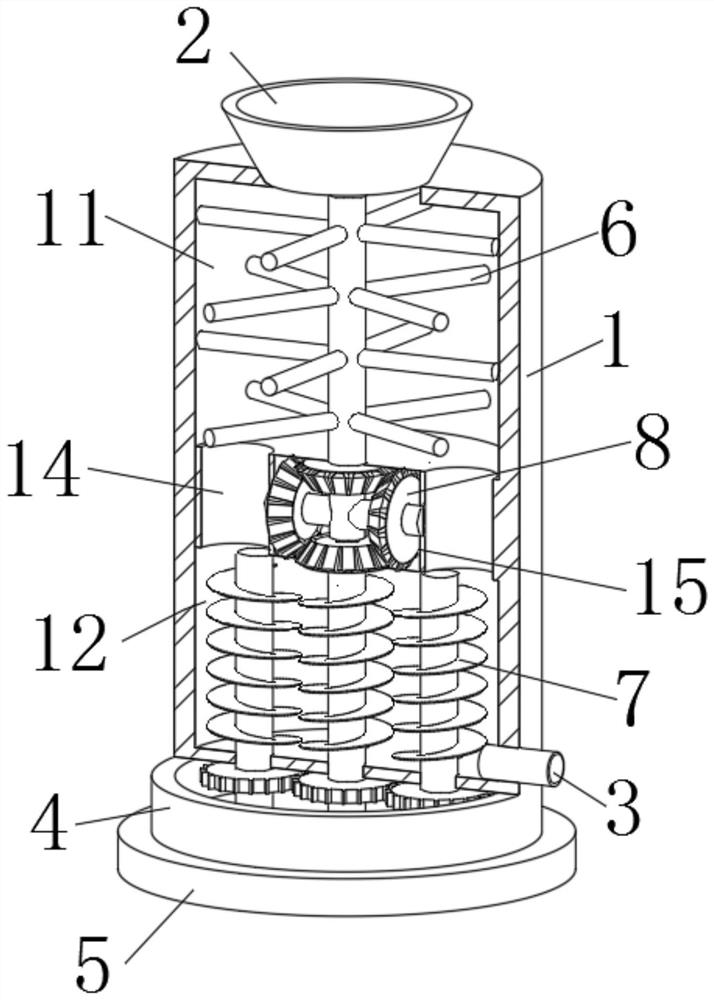

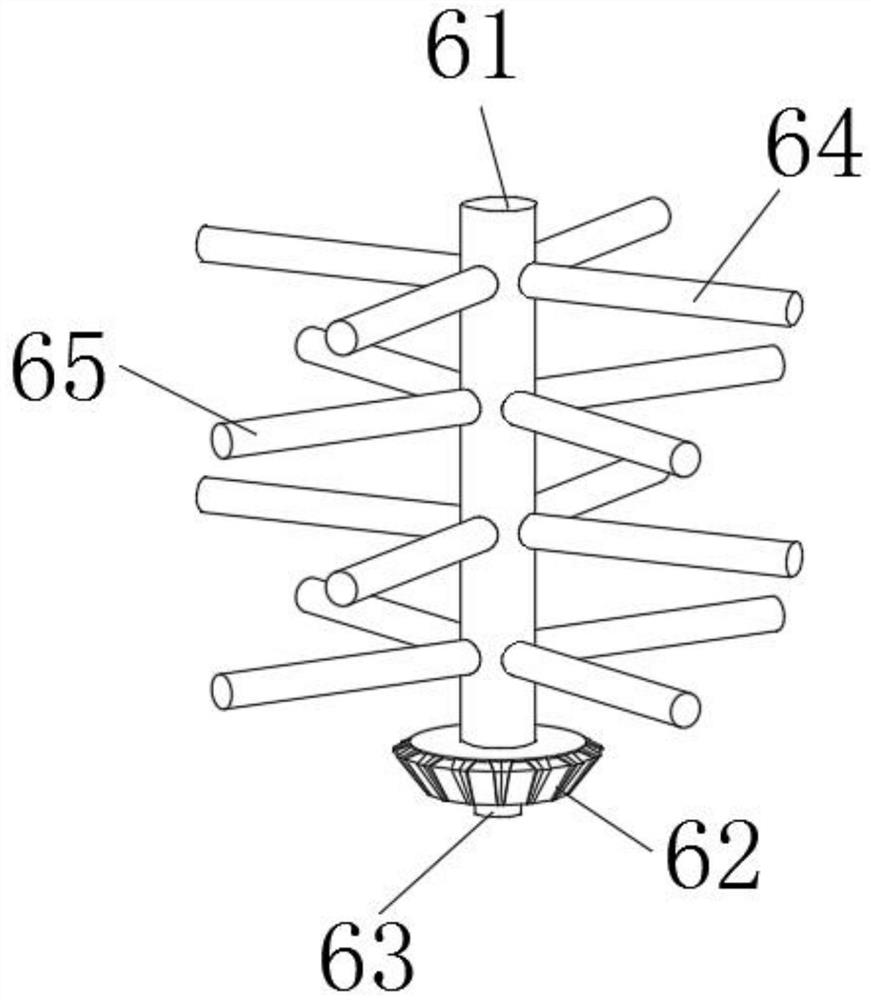

Powder modification tank

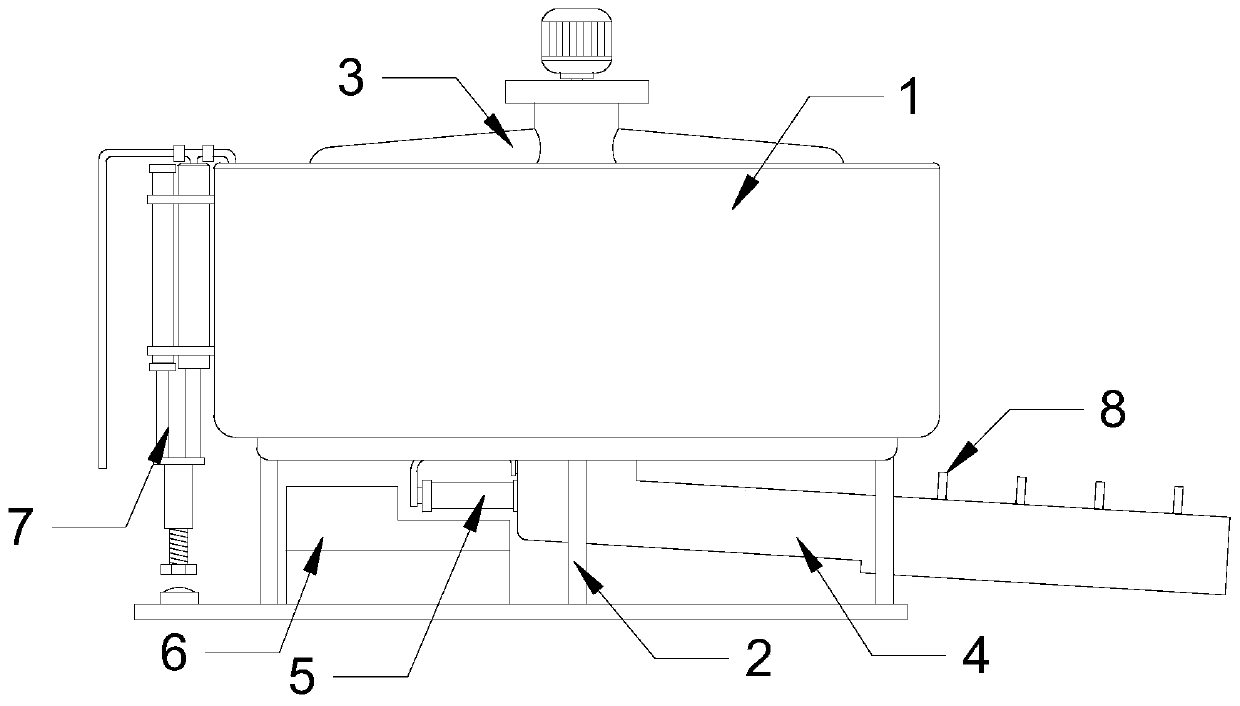

InactiveCN112546996AAccelerateSpeed up the processTransportation and packagingHollow article cleaningPhysicsImpeller

The invention discloses a powder modification tank which comprises a tank body, a support, a powder spraying mechanism, a premixing mechanism, a rotating shaft, an impeller, a supporting rod, a material pushing plate, a scraping plate, a material storage groove, a sealing seat and powder spraying holes; powder is conveyed into the tank body through a feeding port, an external power source drives the rotating shaft to rotate, and the rotating shaft drives the impeller to move along with the rotating shaft; two kinds of modified auxiliary materials uniformly mixed by the premixing mechanism andthe powder spraying mechanism are conveyed into the material storage groove and then sprayed out while rotating along with the rotating shaft through the powder spraying holes; in the process, when powder falls into the tank body, the sprayed auxiliary materials also fall onto the powder and are uniformly mixed through stirring of the impeller, and the supporting rod rotates along with the rotating shaft and can drive the pushing plate and the scraper to rotate at high speed; and on one hand, powder attached to the inner wall of the tank body can be peeled off, and on the other hand, the speedof the powder near the tank body can be increased, and the progress of a modification reaction is accelerated. The device is simple in structure, powder and auxiliary materials are efficiently and uniformly mixed for multiple times, and the modification reaction efficiency and the modification quality are effectively improved.

Owner:马鞍山盛凡智荣信息技术有限责任公司

Fruit juice processing device

InactiveCN112189772ASqueeze fullyEasy to cleanJuice extractionTransportation and packagingFruit juiceReciprocating motion

The invention discloses a fruit juice processing device. The fruit juice processing device comprises a cabinet body; the cabinet body is provided with an inner cavity; a stirring cavity, a filtering cavity and a juicing cavity are formed in the inner cavity; when the fruit juice processing device is in use, fresh fruits enter the juicing cavity from a feeding port, and a rotating motor drives a first crushing shaft to rotate and drives a second crushing shaft to rotate to squeeze out juice of the fruits; when squeezed fruit juice enters the filtering cavity, pomace contained in the fruit juicecan be filtered out through a through hole in the bottom of a drawing box; meanwhile, the drawing box can be drawn out, and pomace in the drawing box can be cleaned conveniently; when the filtered fruit juice enters the stirring cavity through a channel, a second transmission shaft rotates to be in linkage with a rack to do reciprocating motion in a groove; and a rotating gear continuously changes the direction to rotate, so that a stirring shaft is driven to continuously change the direction to rotate, ingredients added into the stirring cavity from an auxiliary material adding port can be more uniformly and efficiently mixed with freshly squeezed fruit juice, and the taste of the prepared fruit juice is improved.

Owner:蒋春梅

Powder-liquid mixing equipment

PendingCN113522074AImprove uniformityImprove quality stabilityRotary stirring mixersMixing methodsEngineeringMechanical engineering

The invention relates to the technical field of powder-liquid mixing, and provides powder-liquid mixing equipment. The powder-liquid mixing equipment comprises a powder-liquid mixing bin (10), wherein the powder-liquid mixing bin (10) comprises a powder-liquid mixing cavity, a powder inlet and a liquid inlet; the powder inlet and the liquid inlet are communicated with the powder-liquid mixing cavity; a powder dispersing part (7), which is arranged at a powder inlet of the powder-liquid mixing bin (10) and is used for dispersing powder into the powder-liquid mixing cavity; and a powder dispersing part, which is used for dispersing powder, the liquid atomizing part is arranged at a liquid inlet of the powder-liquid mixing bin (10) and used for atomizing liquid, wherein, the flow direction of the powder dispersed by the powder dispersing part intersects with the flow direction of the liquid atomized by the liquid atomizing part, so that the dispersed powder and the atomized liquid are fully mixed. According to the powder-liquid mixing equipment, powder and liquid can be mixed more uniformly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mechanized tea leaf production process capable of reducing tea leaf damage

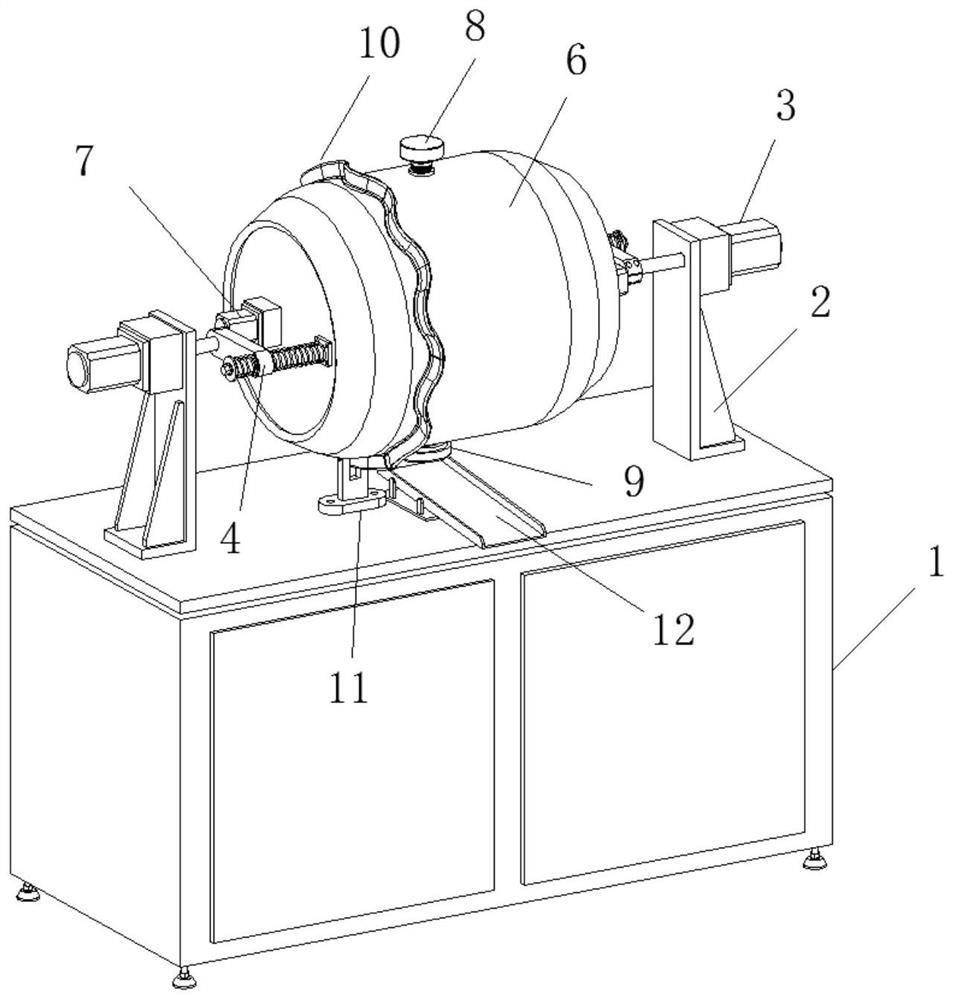

ActiveCN114403243AUniform qualityImprove qualityRotating receptacle mixersPre-extraction tea treatmentProcess engineeringBiology

The invention relates to the technical field of tea production, in particular to a mechanized tea production process capable of reducing tea damage, which comprises the following steps: S1, respectively collecting tea leaves in different production areas, and respectively preparing the tea leaves in each production area into primary tea; s2, preliminarily mixing the raw tea in each production area in proportion to obtain mixed raw tea; s3, the mixed raw tea is input into a material mixing barrel for mechanical blending, the raw tea is automatically output while being blended by the material mixing barrel, blended raw tea with the consistent grade is prepared, the material mixing barrel is horizontally placed, when the material mixing barrel is used for blending tea leaves, the material mixing barrel rotates, the blade track rotates along with the material mixing barrel, and the raw tea rotates along with the blade track and is output from the material mixing barrel; according to the production process, the tea leaves in various regions can be uniformly blended to the maximum extent, the quality stability of the tea leaves in the same batch is effectively maintained, the integrity of the tea leaves is maintained, and the production process has the advantage of being high in tea blending efficiency.

Owner:SOUTH CHINA AGRI UNIV

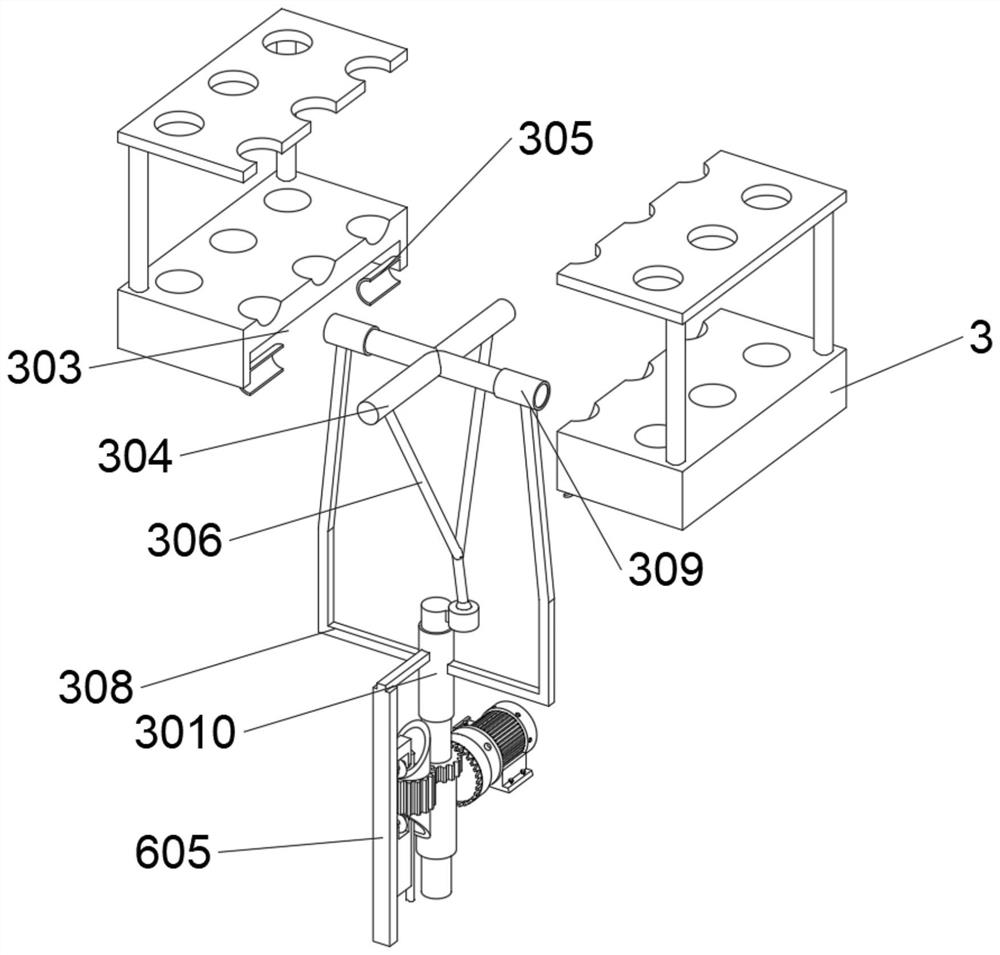

Petroleum processing treatment equipment in petro-chemical machinery field

InactiveCN107570069AMeet processing needsLow costShaking/oscillating/vibrating mixersMechanical fieldPetroleum processing

The invention discloses petroleum processing treatment equipment in a petro-chemical machinery field. The petroleum processing treatment equipment comprises a first frame device, a cover plate device,a concentration plate device, a second frame device and an electro-cylinder device, wherein the cover plate device is arranged at the upper end of the first frame device; the concentration plate device is arranged in the first frame device; the second frame device is arranged at the lower end of the first frame device; the electro-cylinder device is positioned below the second frame device. The treatment equipment disclosed by the invention can realize full mixing, is uniform in mixing and high-efficiency, can meet the petroleum processing needs, and is simple in operation, convenient to use,low in cost and suitable for popularization and application.

Owner:蒙丽桃

Purification device for traditional Chinese medicine production

PendingCN111494981AEasy to add quantitativelyFeeding volume adjustmentSolid solvent extractionStationary filtering element filtersProcess engineeringIndustrial engineering

The invention discloses a purification device for traditional Chinese medicine production and processing, and belongs to the field of traditional Chinese medicine processing. The invention discloses apurification device for traditional Chinese medicine production. The device comprises a tank body, a bottom frame, a stirring mechanism, a discharging square pipe, a switching mechanism, an electriccontrol box, a liquid injection mechanism, a filtering mechanism and a discharging port; a bottom frame is fixed to the bottom of the tank body, a discharging port is formed in the center of the bottom face of the tank body, a discharging square pipe communicated with the discharging port is fixed to the bottom face of the tank body, a filtering mechanism is placed on the inner side of the end ofthe discharging square pipe, a switching mechanism is installed at the end, close to the tank body, of the discharging square pipe, and a liquid injection mechanism is installed on the outer wall of the tank body. Traditional Chinese medicine solvents are fully mixed through the stirring mechanism, the purification efficiency and precision are improved, adjustable quantitative solvent adding is achieved through the liquid injection mechanism, solvent waste is reduced on the premise that medicine components are fully absorbed, and the processing economy is improved.

Owner:陈宝强

Water-based paint stirrer

PendingCN108067114AReasonable structureStir wellRotary stirring mixersTransportation and packagingMotor protectionKnife blades

The invention discloses a water-based paint stirrer, which comprises a support plate, a transmission shaft and a stirring rod, wherein a motor is arranged inside a motor protection cover; a fixing device is fixedly connected between the transmission shaft and the stirring rod; a bottom groove is formed in the bottom end surface of a base; a first L cutter blade, a second L cutter blade, a third Lcutter blade and a fourth L cutter blade are uniformly and fixedly connected with the edge of the base; the edge of the base is fixedly connected with a first S cutter blade in a position between thesecond L cutter blade and the third L cutter blade; the edge of the base is fixedly connected with a second S cutter blade in a position between the first L cutter blade and the fourth L cutter blade.The water-based paint stirrer has the advantages that the structure is reasonable; water-based paint can be efficiently and uniformly mixed in the use process; the S cutter blades and the L cuter blades are creatively combined, so that the stirring is more uniform; the use efficiency is greatly improved.

Owner:天津市安第斯科技有限公司

Underwater water-gas mixer

PendingCN109999683AEfficient mixingMix evenly and efficientlyTransportation and packagingMixer accessoriesWater flowProduct gas

The invention relates to the technical field of aeration, in particular to an underwater water-gas mixer. The mixer includes an air supply pipe and a first water-gas mixing part, wherein the first water-gas mixing part is vertically put under the water surface, the first water-gas mixing part includes a bottom plate, and the center of the bottom plate extends vertically to any one side surface ofthe bottom plate so as to form an air outlet through pipe; a plurality of through holes for allowing water to flow through are formed in the bottom plate, a distance difference is arranged between a plane in which the first air outlet of the air outlet through pipe is formed and a plane in which the bottom plate is arranged, and the air supply pipe is connected to the air outlet through pipe; anda first side wall is formed on the side, in the direction in which the air outlet through pipe is formed, of the periphery of the bottom plate, and a pressure difference is generated by gas dischargedfrom the first air outlet, so that water flow is driven to move through the through holes from the outside in, and the water is mixed with gas of the first air outlet.

Owner:邹权明

3D printing device and printing method for integrated manufacturing of functionally graded materials and structures

ActiveCN111284004BRealize integrated manufacturingAchieve preparationAdditive manufacturing apparatus3D object support structuresEngineeringControl valves

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

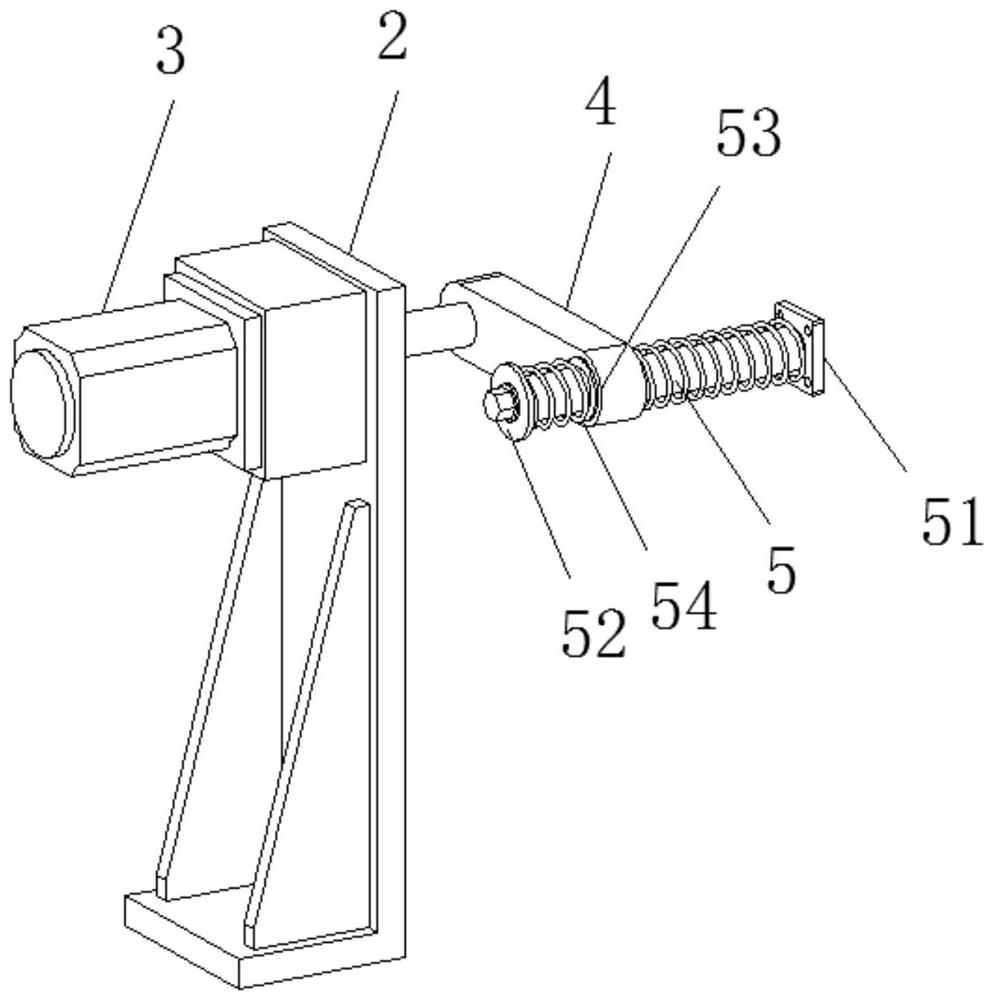

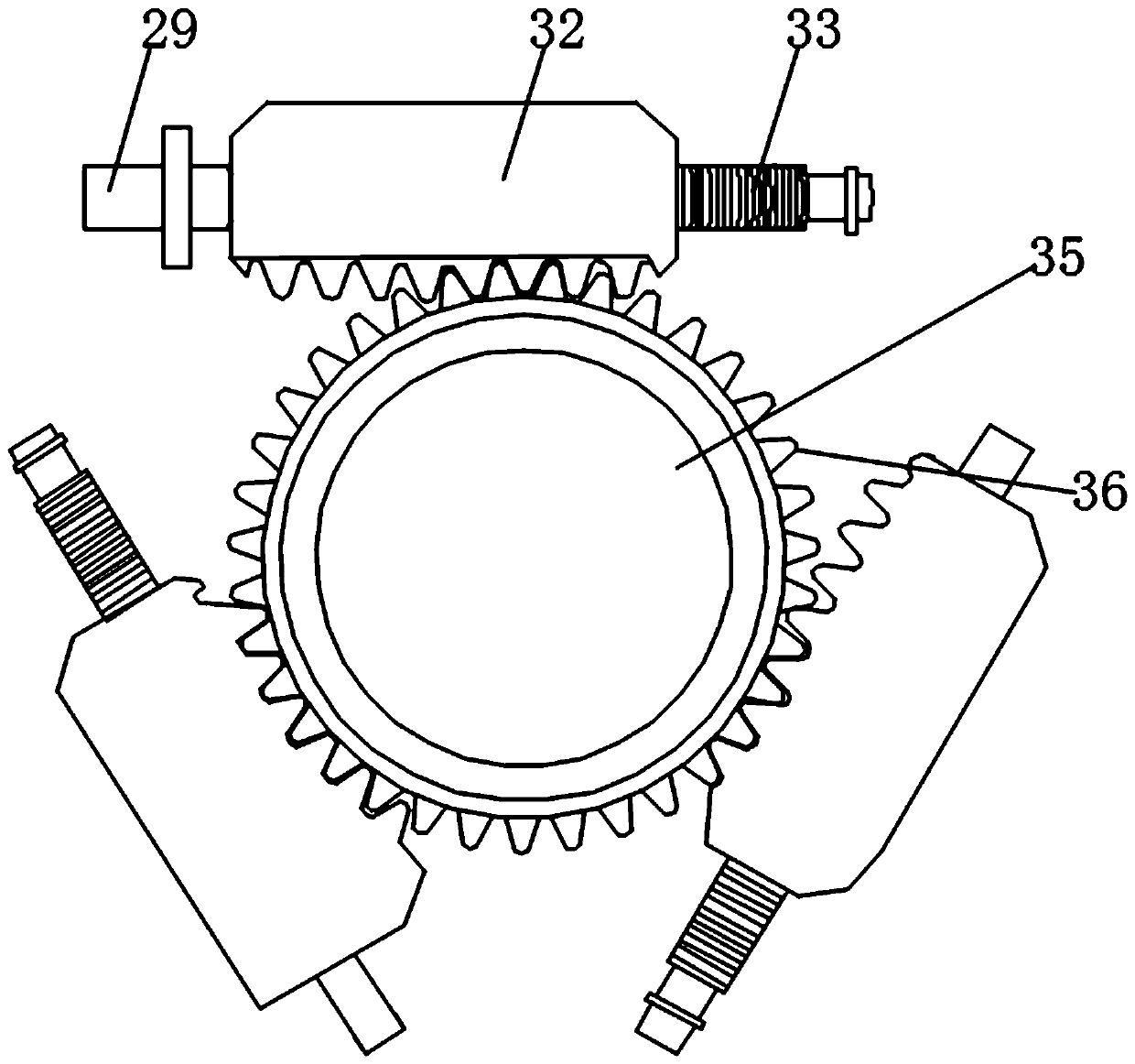

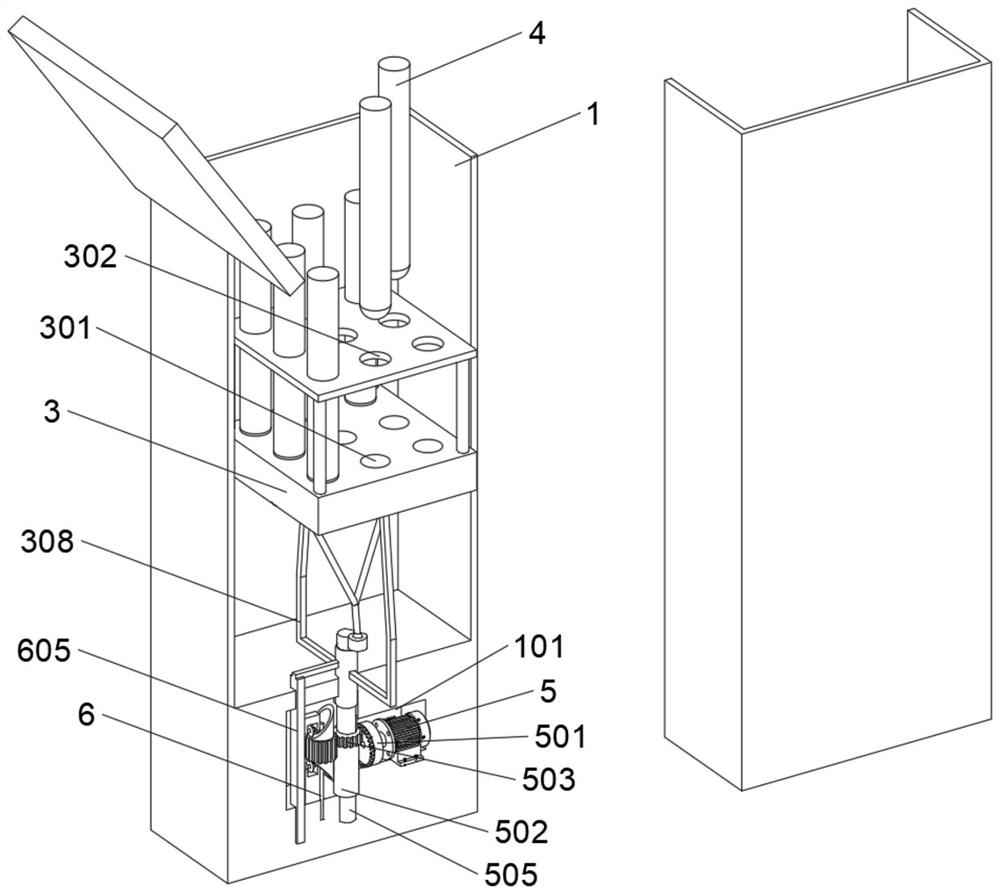

Stirring and puffing device for konjak vegetarian cattle stomach

InactiveCN110731528AWell mixedEasy to mix quantitativelyShaking/oscillating/vibrating mixersTransportation and packagingAnimal scienceMedicine

The invention discloses a stirring and puffing device for konjak vegetarian cattle stomach. The stirring and puffing device for konjak vegetarian cattle stomach comprises a quantitative structure, a pushing structure and a stirring auxiliary structure, wherein the quantitative structure comprises a No.1 moving block, a No.2 moving block, a No.3 moving block and a limiting structure; the No.1 moving block comprises a limiting block; a transmission threaded rod is movably connected to one end of the limiting block; a gear screw column is arranged at the middle of the transmission threaded rod; atransmission wheel is arranged at the middle of the limiting structure; the middle part of the transmission wheel is hollow to be used for allowing raw materials to be transmitted; a gear is in meshing connection to one end of the gear screw column, and is located outside the transmission wheel; and the size and the structure of the No.2 moving block and No.3 moving block are the same as those ofthe No.1 moving block. The stirring and puffing device for konjak vegetarian cattle stomach disclosed by the invention is convenient for limit quantity; the stirring control is accurate; quantitativeraw materials can be added; the angle and the height of the stirring are increased; the stirring can be sufficient, the stirring time can be shortened, and the production efficiency can be improved.

Owner:ANHUI SPICY MAGIC KING FOOD CO LTD

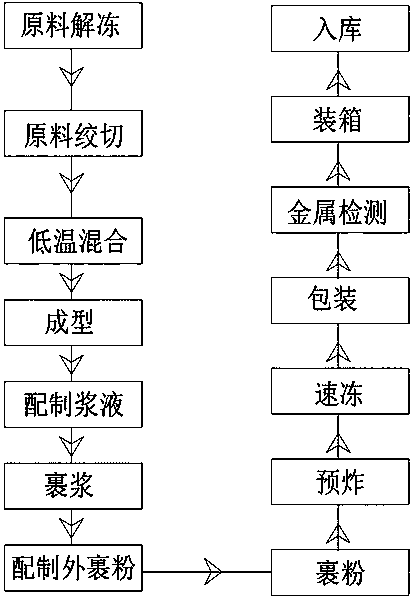

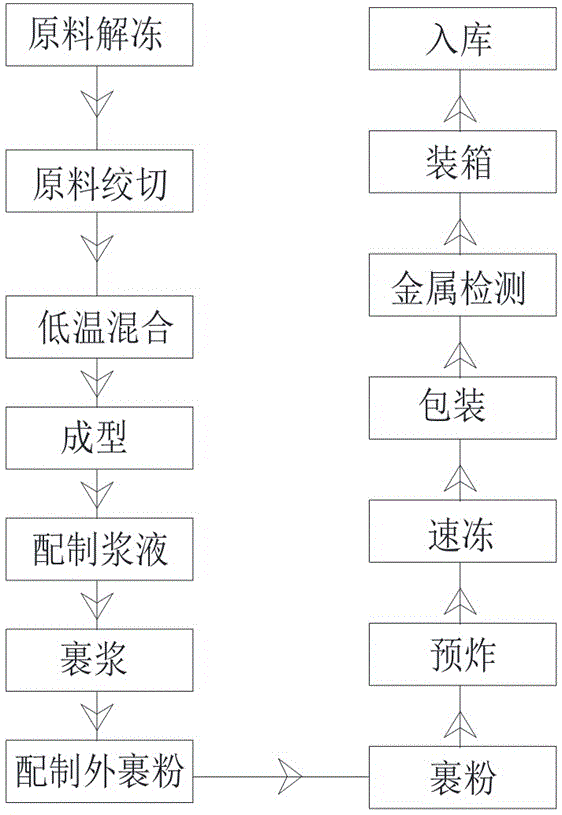

Gristle and meat crisp quick-frozen food and production method thereof

InactiveCN109315707AIncrease appetiteMix evenly and efficientlyFood scienceMolding machineRaw material

The invention discloses gristle and meat crisp quick-frozen food and a production method thereof. The gristle and meat crisp quick-frozen food is made by using shredded chest gristle, leg meat and / orbrisket of poultry as raw materials; the production method comprises the steps of mincing the raw materials into diced meat in a meat mincer by using a screen board with a diameter of 10mm, then pouring the diced meat into a nitrogen mixer, and adding auxiliary materials and seasonings; then, using a molding machine to perform extrusion molding on the low-temperature meat paste, hanging pulp, wrapping with powder or crumbs, prefrying, quick-freezing, packaging, carrying out metal detection, boxing and putting into a storage so as to obtain the gristle and meat crisp quick-frozen food. The method can utilize the raw materials efficiently, thus increasing the utilization rate of the raw materials, and reducing the production cost; furthermore, the method adopts a mechanical operation method,thus increasing the production efficiency and lowering the human resource cost; meanwhile, the gristle and meat crisp product produced by the method is crispy in taste and better in color, thus having a better edible effect.

Owner:黄静仪

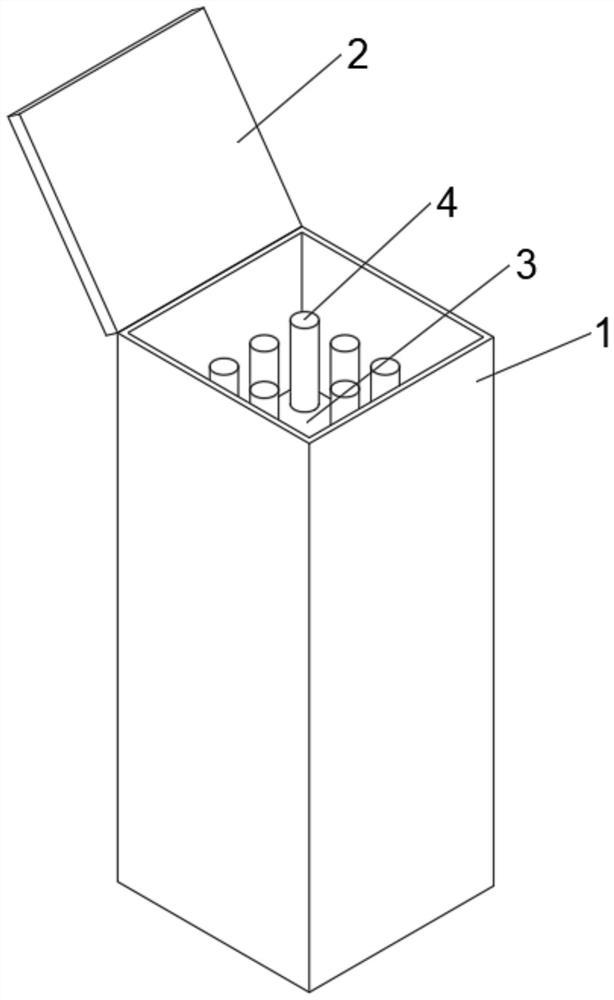

Oscillation device for clinical medical examination

InactiveCN112871038AGuaranteed accuracyOscillate fullyShaking/oscillating/vibrating mixersTransportation and packagingEngineeringApparatus instruments

The invention discloses an oscillation device for clinical medical examination, and belongs to the technical field of medical instruments. The on oscillation device for clinical medical examination comprises an examination box body, a to-be-tested reagent is placed in a storage through hole, an oscillation cavity is formed in the bottom face of a reagent examination storage frame, a triangular oscillation rod is arranged below a cross-shaped oscillation frame, and a U-shaped oscillation auxiliary supporting frame is arranged on the lower side in the examination box body, a cylinder is arranged in the middle of the lower side of the U-shaped oscillation auxiliary supporting frame, the upper end of a reciprocating column penetrates through the interior of the cylinder to extend to the exterior and is welded with an eccentric column, and the structures are in close fit, so that the triangular oscillation rod below can sufficiently oscillate a mixed reagent back and forth like an arm, and the mixed reagent is uniformly mixed, therefore, the reaction can be fully carried out, the influence of centrifugal force is effectively avoided, the phenomenon that the concentration at one side is high and the concentration at the other side is low is avoided, the oscillation effect is improved, the high efficiency and uniformity of mixing are ensured, and the accuracy of an inspection result is ensured.

Owner:侯家涛 +1

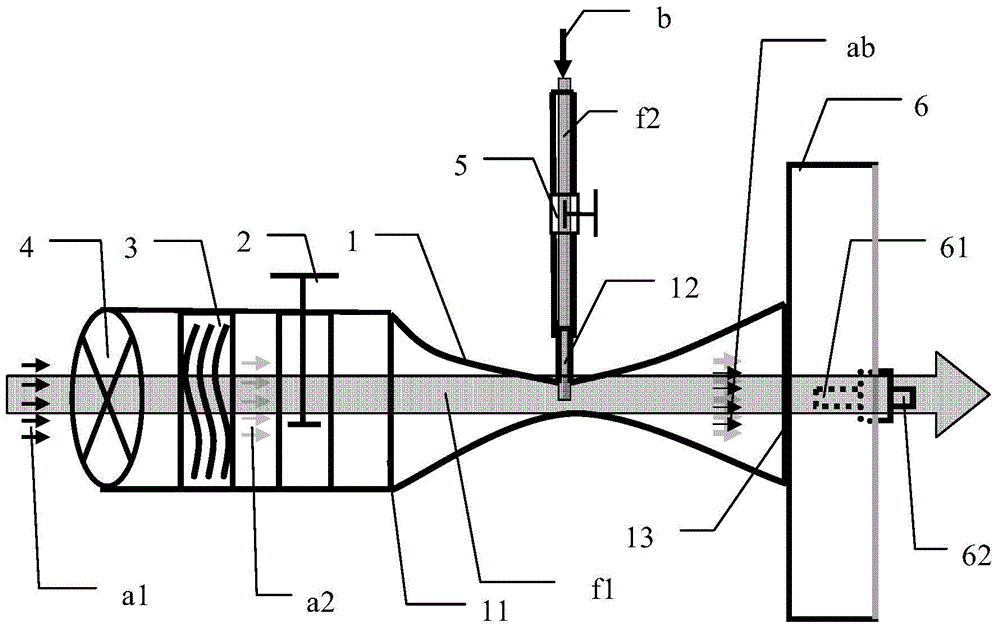

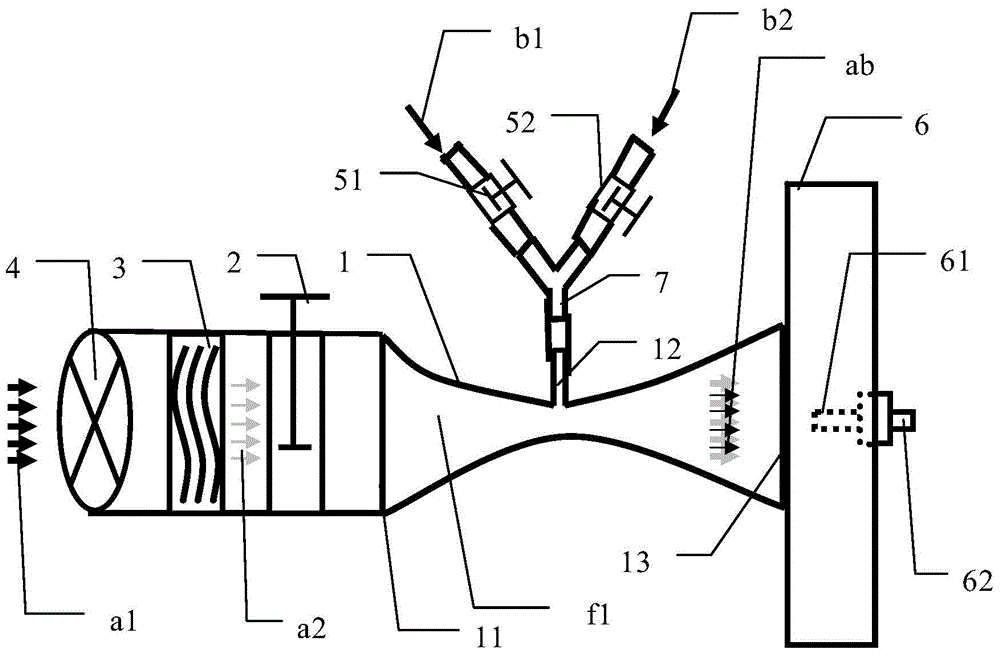

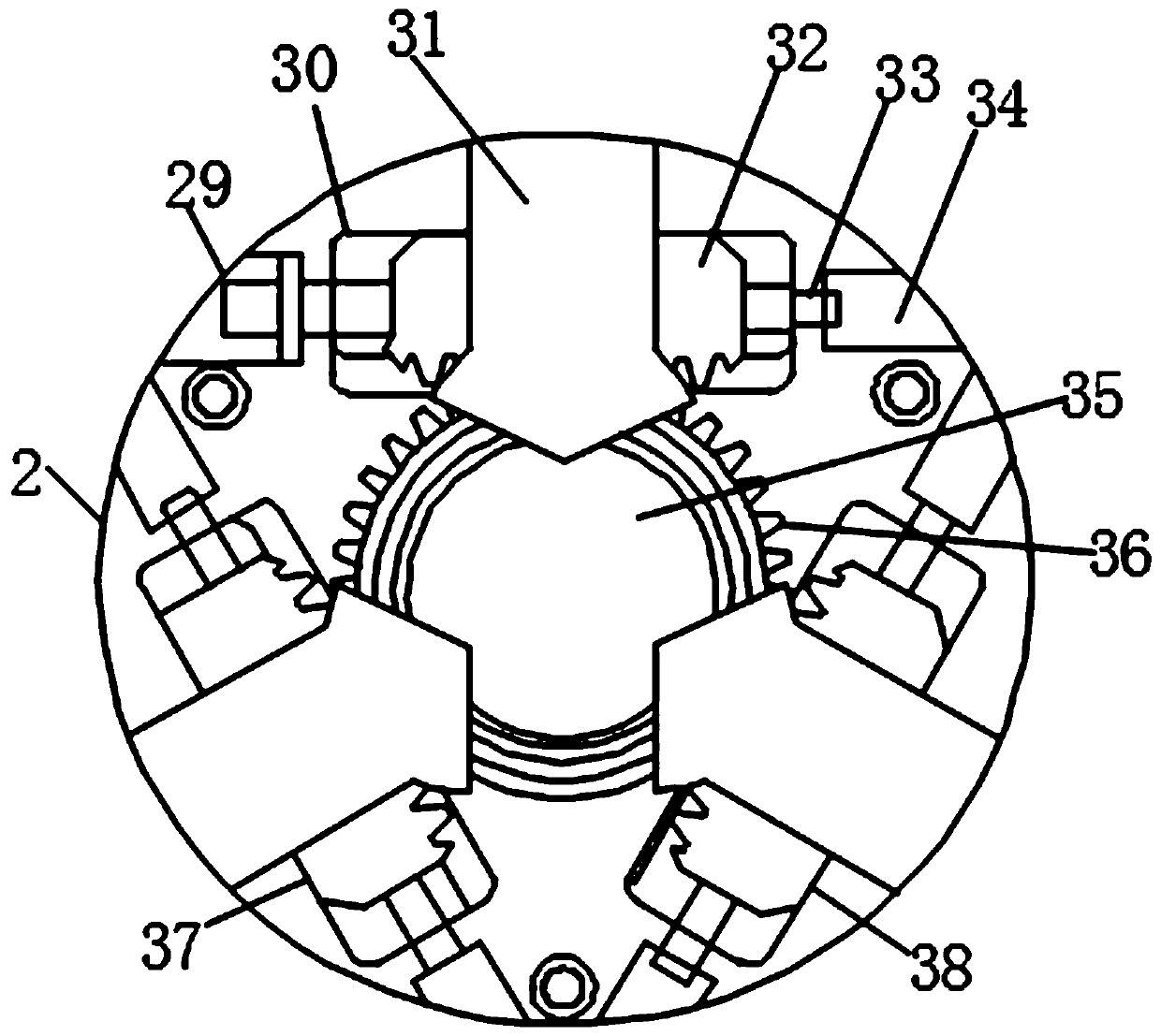

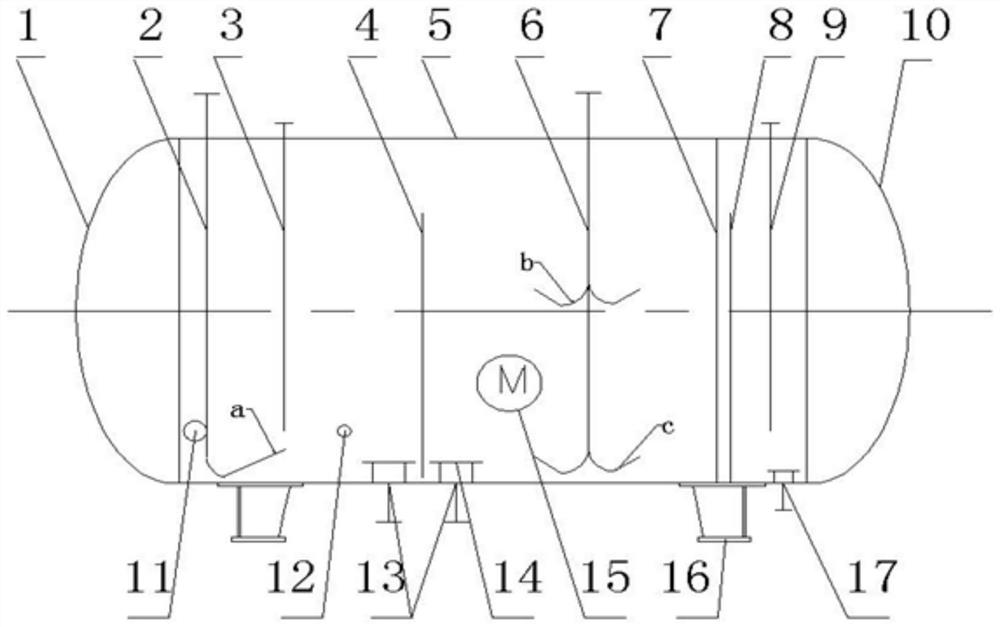

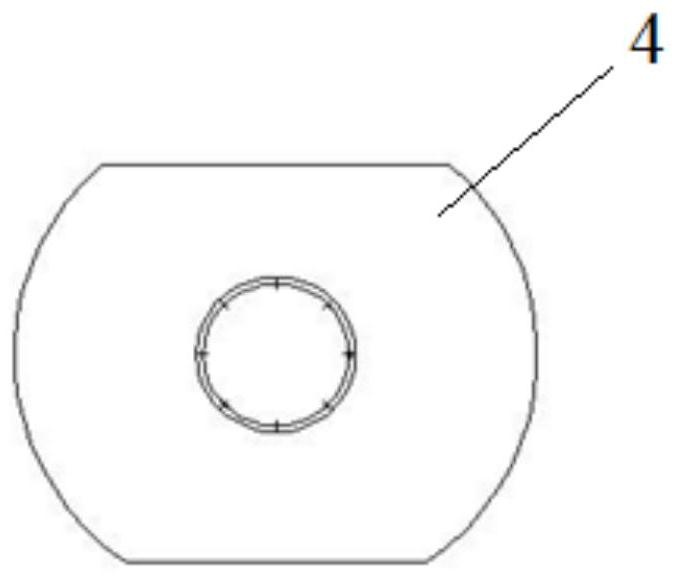

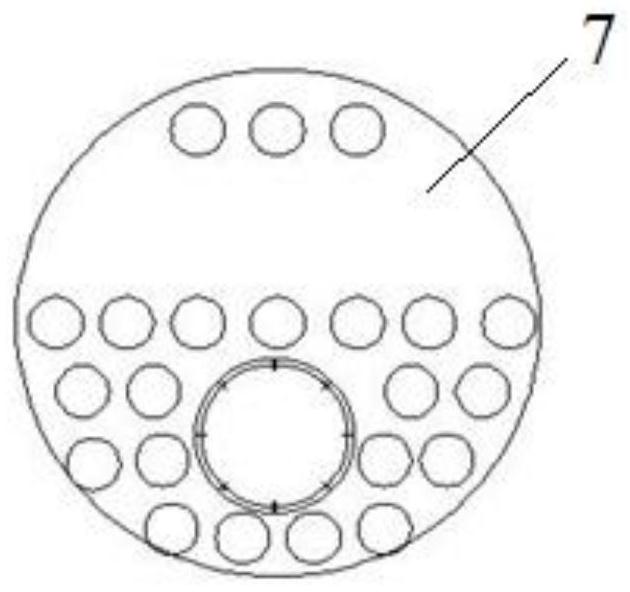

Reactor for the recovery of by-product acetonitrile in the production process of acrylonitrile

ActiveCN108543506BMix evenly and efficientlyRapid responseProductsReagentsAcrylonitrileProcess engineering

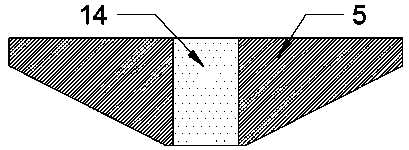

The embodiment of the present invention relates to a reactor for the recovery of acetonitrile by-product in the production process of acrylonitrile, comprising a cylinder body (5), a left end head (1) and a right end head (10). ) is provided with a first circulating mixed reaction liquid inlet (2), a feed pipe (3) and a second circulating mixed reaction liquid inlet (6) along the direction of the centerline of the longitudinal vertical cross section of the reactor; The circulating mixed reaction liquid inlet (6) is connected with an upper two-way injector (b) and a lower two-way injector (c), and the circulating mixed reaction liquid inlet (2) is connected with a one-way injector (a). The object of the present invention is to provide an energy-saving and efficient reactor for the recovery of the by-product acetonitrile in the production process of acrylonitrile.

Owner:中石油吉林化工工程有限公司

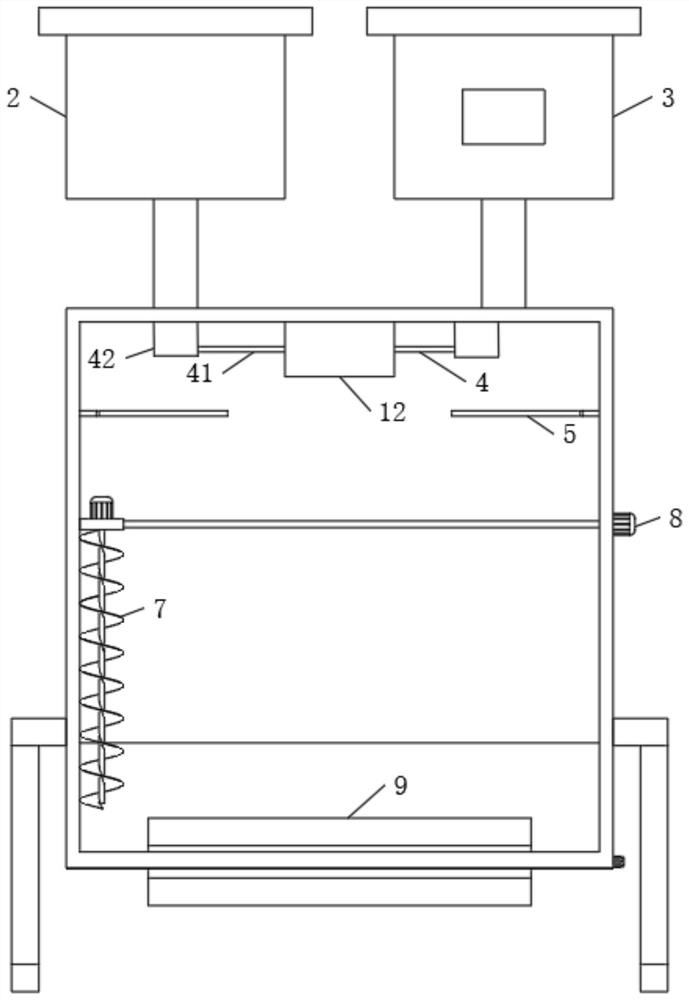

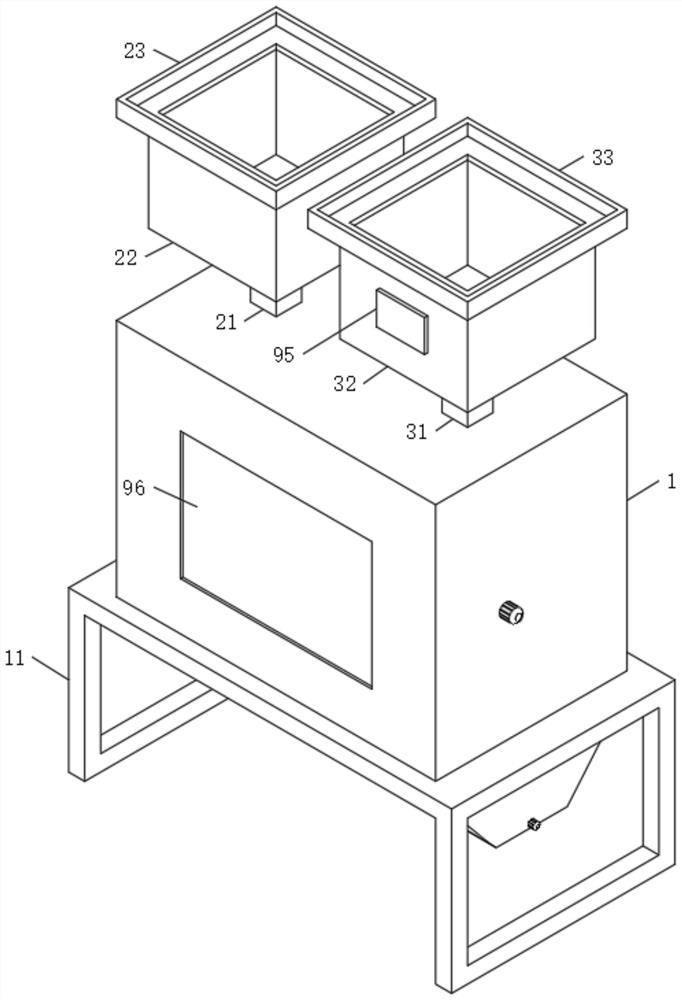

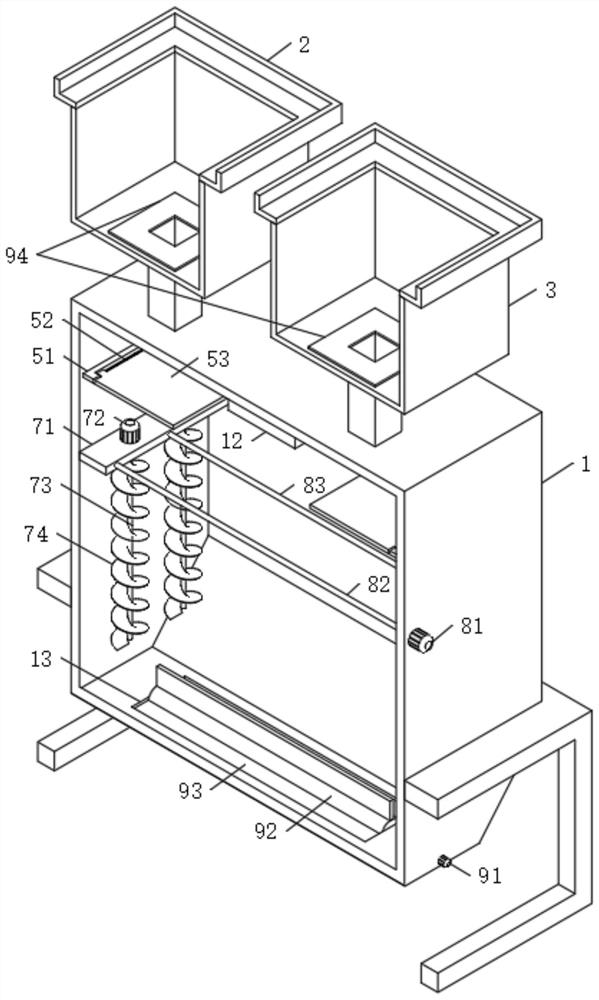

Automatic batching device for cement production

PendingCN114750296AImprove efficiency and qualityImprove efficiencyDischarging apparatusMixing operation control apparatusPhysicsProcess engineering

The invention provides an automatic batching device for cement production, which comprises a mixing box, a flow guide mechanism, a mixing mechanism and a moving mechanism, a base is fixedly mounted at the bottom of the mixing box, a first feeding mechanism and a second feeding mechanism are respectively mounted on two sides of the top of the mixing box, and a mounting box is fixedly mounted on the inner top wall of the mixing box. A driving assembly is mounted in the mounting box, opening and closing assemblies used for discharging materials to the first feeding mechanism and the second feeding mechanism are arranged on the two sides of the mounting box, the two flow guide mechanisms are located below discharging openings of the first feeding mechanism and the second feeding mechanism correspondingly, and the mixing mechanism is mounted in the mixing box; and the moving mechanism is mounted in the mixing box. According to the automatic batching device for cement production, provided by the invention, a grinding aid and a cement raw material can be intermittently put into the mixing box in sequence, so that the grinding aid and the cement raw material are thoroughly mixed.

Owner:WUHAI XISHUI CEMENT

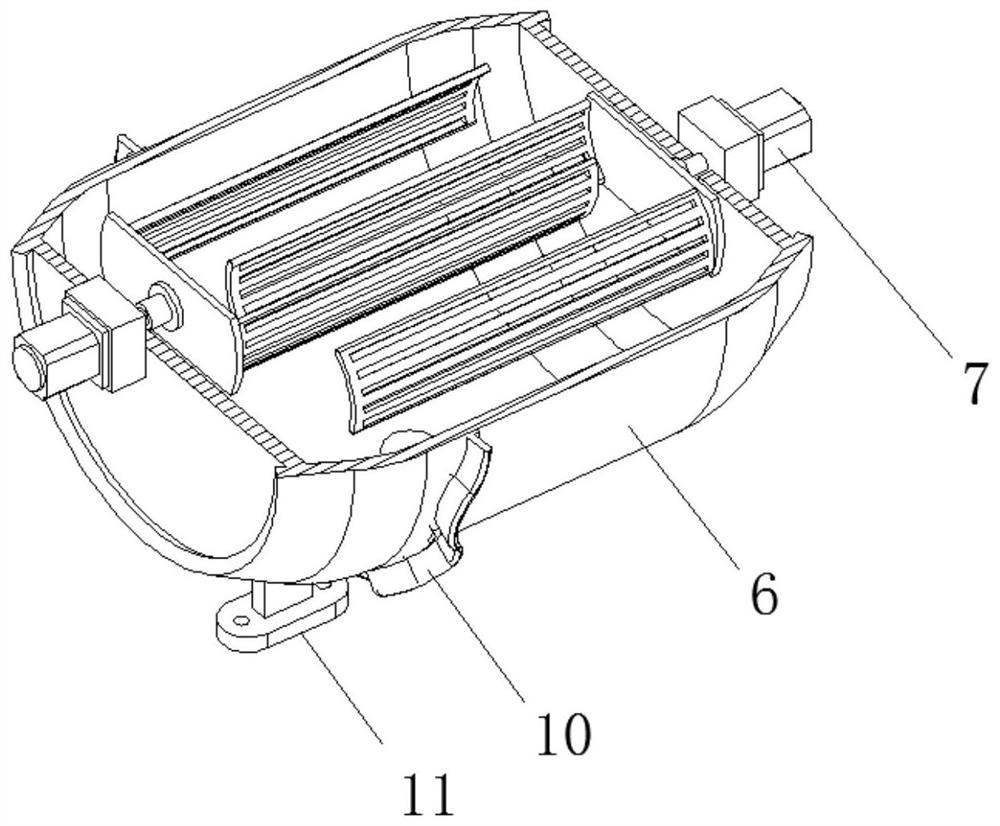

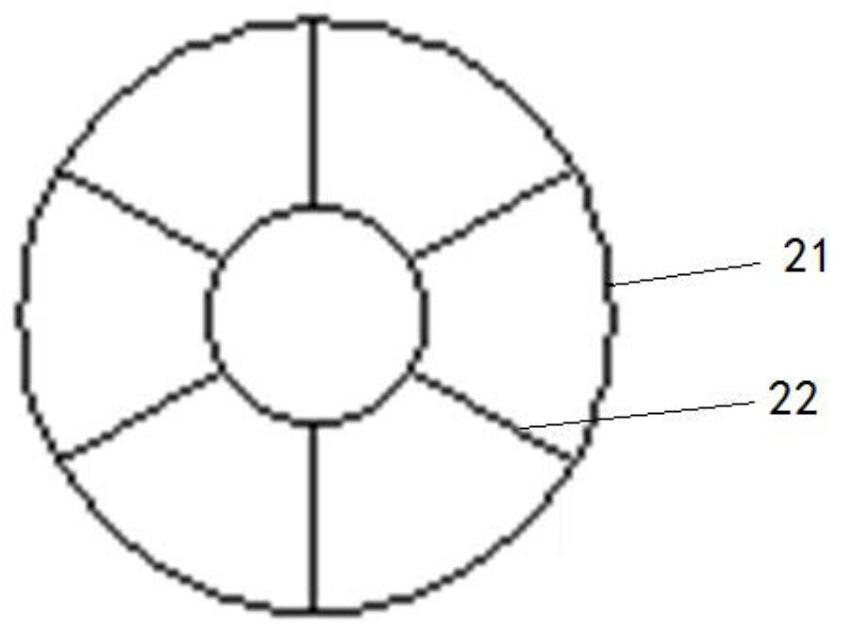

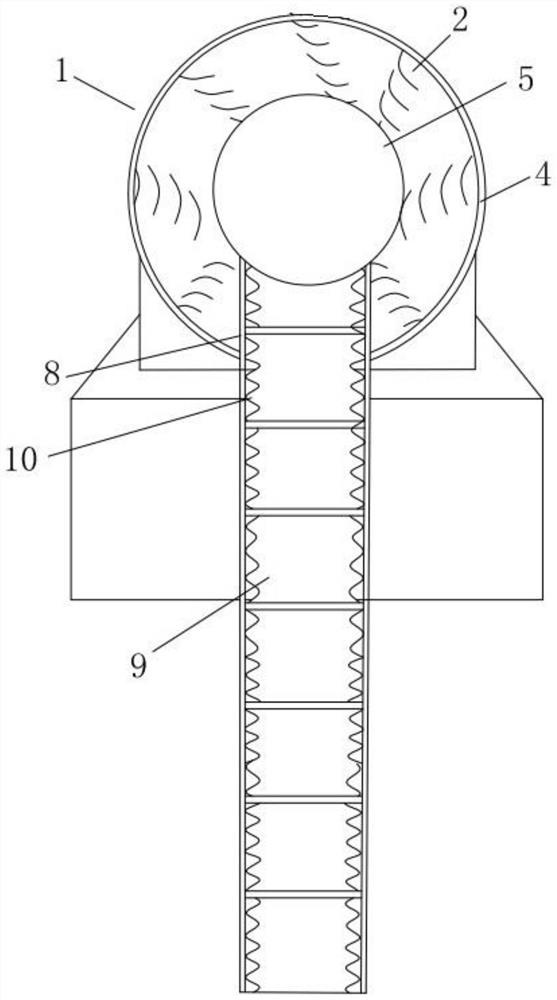

Tea blending machine

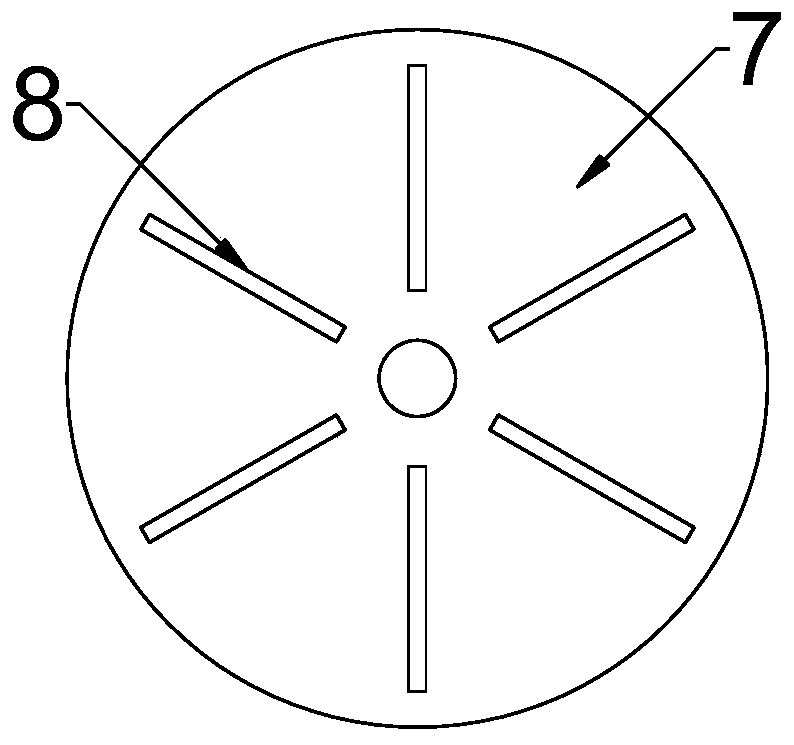

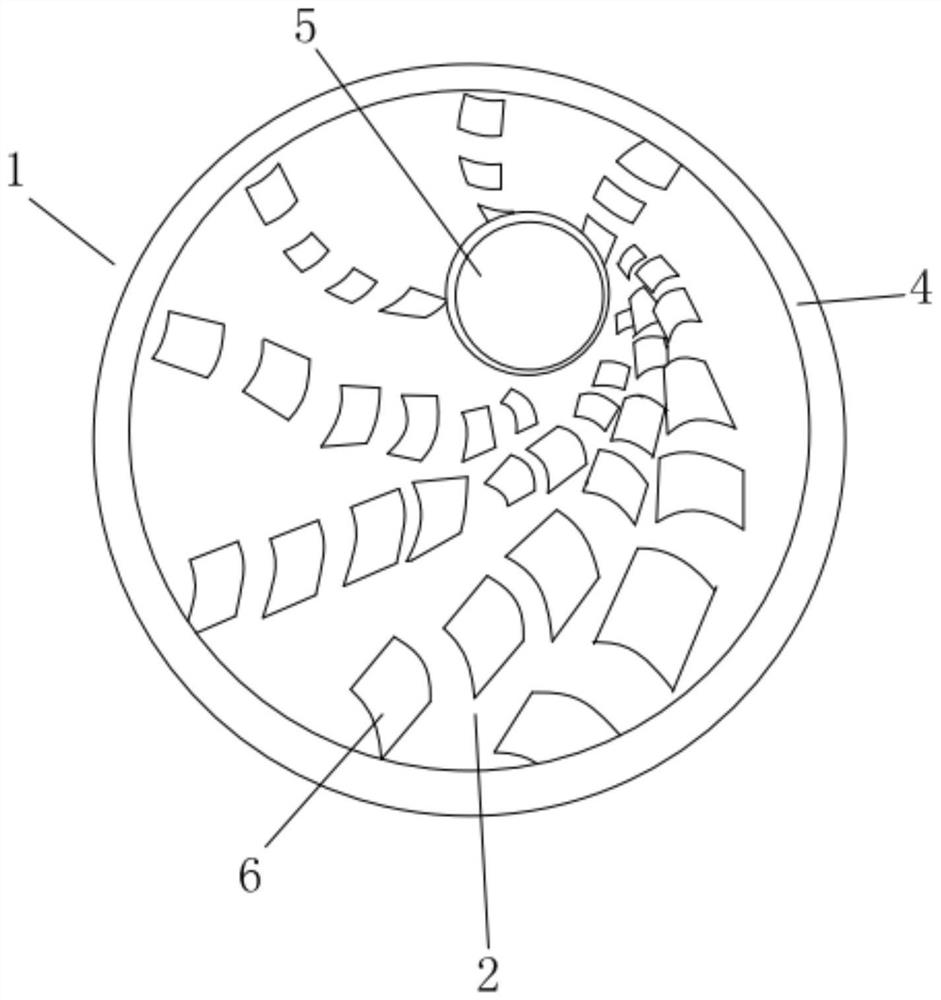

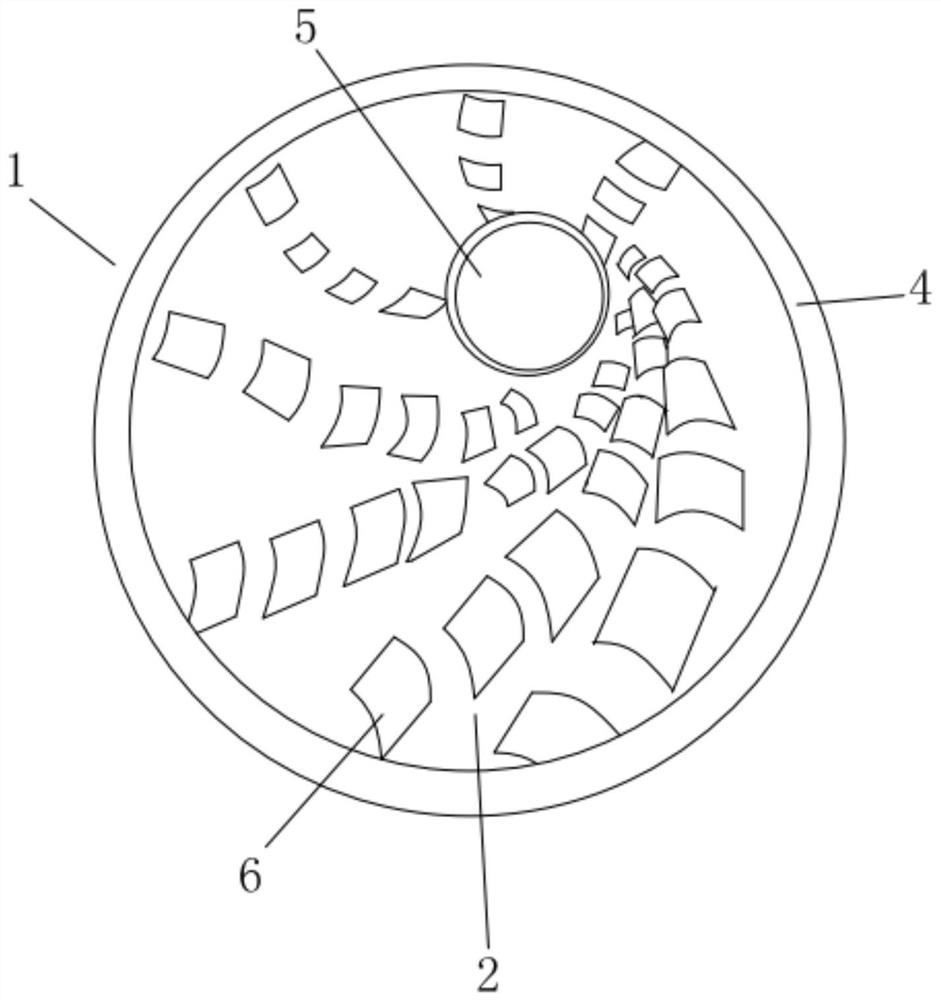

PendingCN114377584AWell mixedIntegrity guaranteedRotating receptacle mixersPre-extraction tea treatmentEngineeringMixing effect

The invention relates to the technical field of tea production, in particular to a tea blending machine which comprises a horizontally-arranged mixing barrel, the mixing barrel can rotate around the central axis of the mixing barrel, at least two blade tracks are arranged in the mixing barrel, each blade track spirally extends along the inner wall of the mixing barrel, and the blade tracks are arranged on the inner wall of the mixing barrel. Each blade track extends from a feed port of the mixing barrel to a discharge port of the mixing barrel, the adjacent blade tracks are aligned and extend, each blade track is composed of a plurality of inclined blades, each inclined blade is bent and arched back to the inner wall surface of the mixing barrel, and the inclined blades are arranged on the inner wall surface of the mixing barrel. The adjacent inclined blades on the same blade track are arranged in an aligned mode, the bent faces of the inner sides of the inclined blades between the adjacent blade tracks are opposite, and the tea blending machine can automatically and evenly mix tea of all qualities in a damage-free mode and has the advantages of being good in mixing effect and high in mixing speed.

Owner:广东青云茶业有限公司 +1

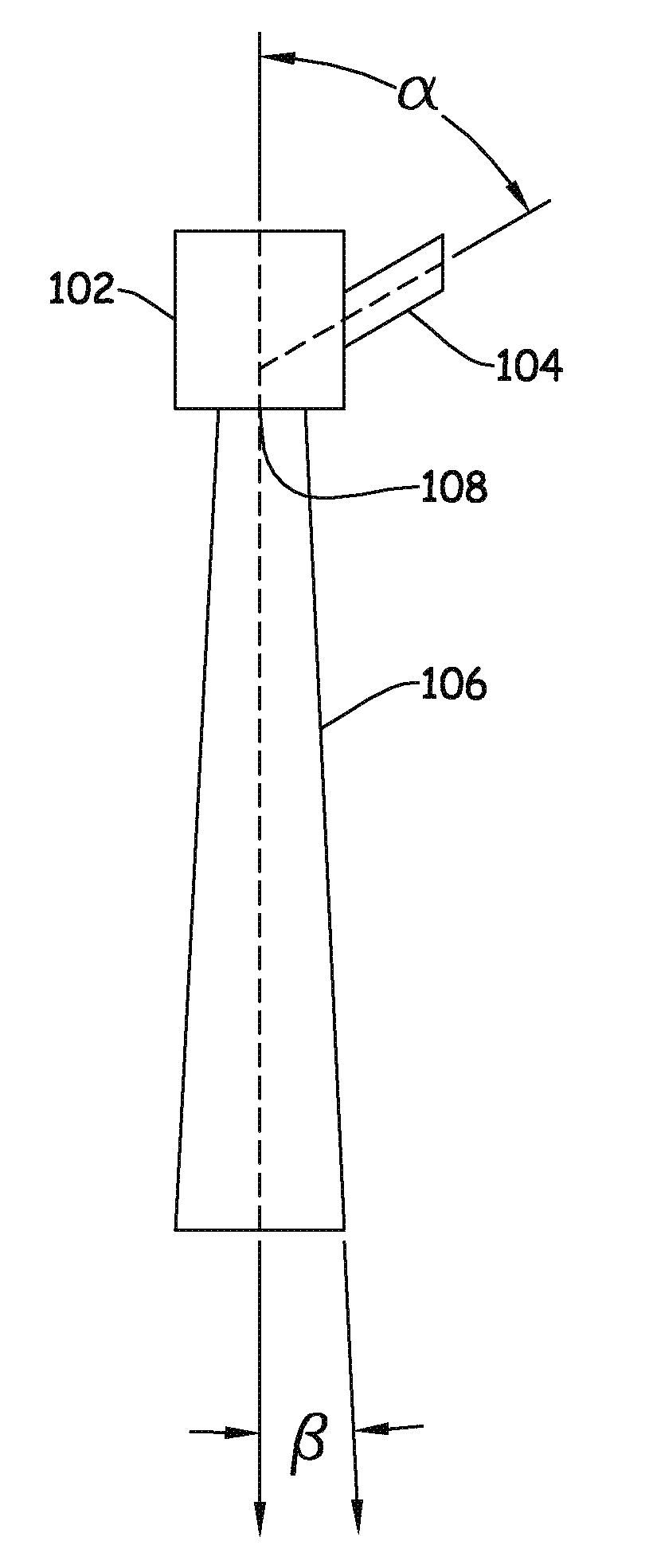

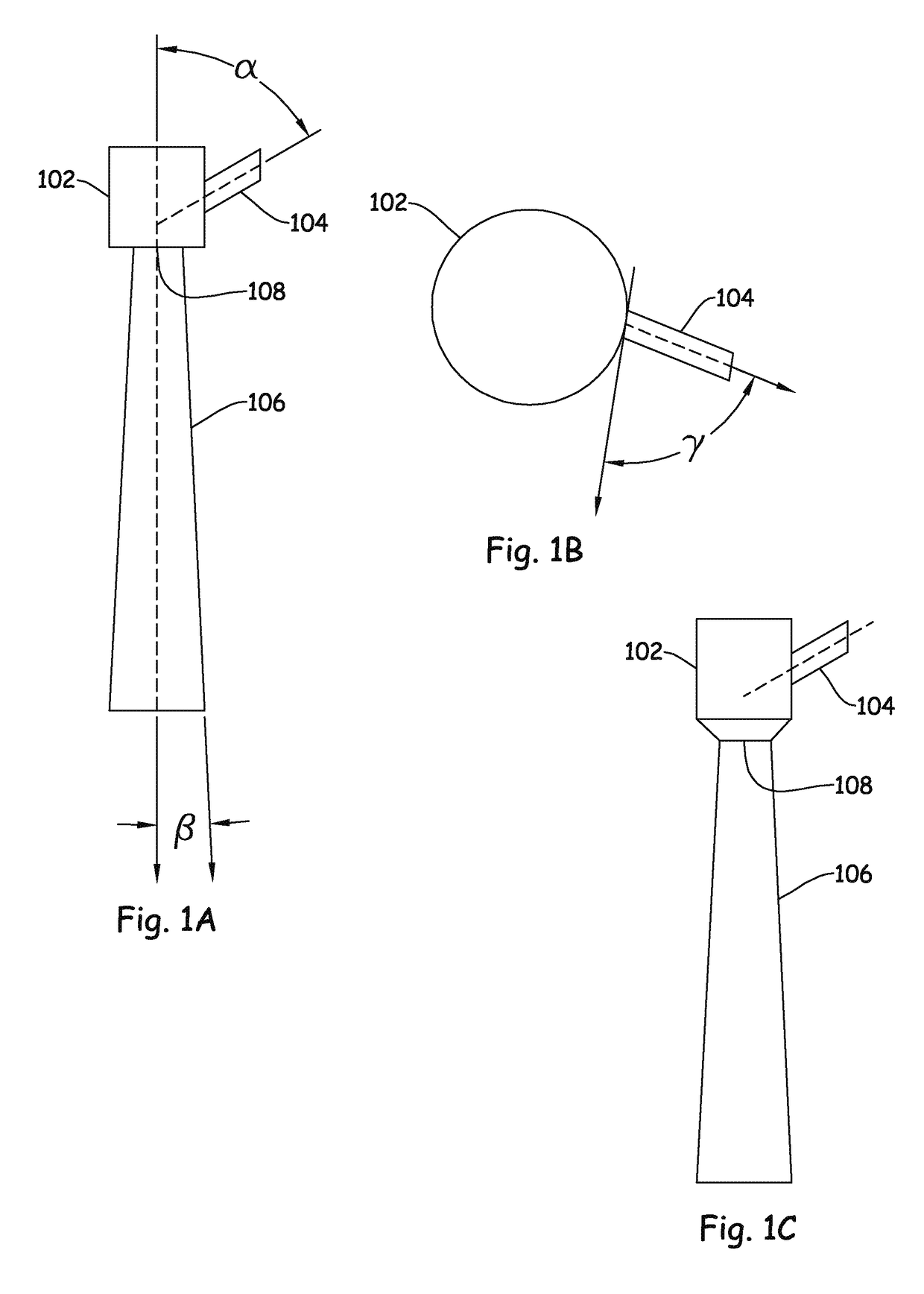

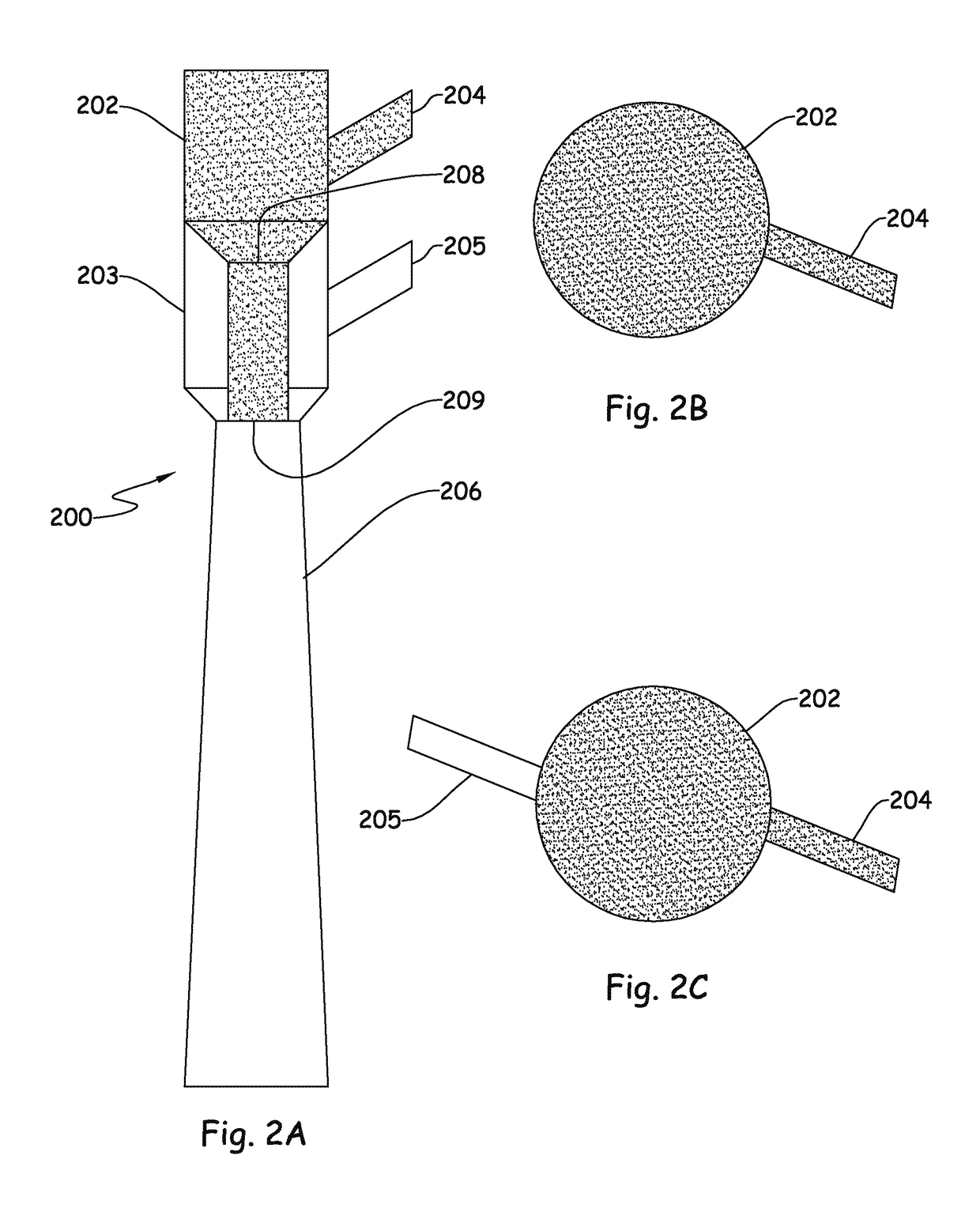

Mixer and processes incorporating the same

InactiveUS20160158715A1Convenient to accommodateLow costFlow mixersTransportation and packagingProcess engineeringEngineering

Owner:BLUE CUBE IP

Solvent equal-ratio blending device for disinfectant production

InactiveCN114272822ASpeed up blendingIncrease speedShaking/oscillating/vibrating mixersTransportation and packagingCircular discElectric machinery

The invention belongs to the technical field of disinfectant production, and particularly relates to a disinfectant production solvent equal-proportion blending device which comprises a box body, a box cover is arranged at the top of the box body, a vertical pipe is fixed to the top of the box cover in a penetrating mode, a main shaft is rotationally connected to the inner wall of the bottom of the vertical pipe, an incomplete bevel gear is fixed to the main shaft in a sleeving mode, and the bottoms of the two sides of the vertical pipe communicate with transverse pipes; a split shaft penetrates through and is rotationally connected to the side wall of the transverse pipe, a complete bevel gear is fixed to the inner side of the split shaft and is in meshed connection with the incomplete bevel gear, a motor is fixed to the top of the vertical pipe, an output shaft of the motor is fixed to the main shaft, a disc is fixed to the outer side of the split shaft, a plurality of first sliding grooves are formed in the outer side of the disc, and first sliding blocks are slidably connected into the first sliding grooves. A stirring paddle is fixed on the outer side of the first sliding block. In the invention, the incomplete bevel gear and the two complete bevel gears are respectively in a meshed state and a non-meshed state at the same moment, and the stirring paddles on the two discs have a rotating speed difference, so that the blending efficiency is improved.

Owner:江苏康巴特生物工程有限公司

A kind of production method of quick-frozen food with crispy bone and meat prepared by using poultry bone meat

The invention discloses a quick-frozen crispy meat crispy food prepared by using poultry flesh and bone and a production method thereof. The crispy bone quick-frozen meat crispy food uses the poultry's broken breast cartilage, leg meat and / or breast meat as raw materials, and is crushed in a meat grinder. The raw materials are minced with a mesh plate with a diameter of 10mm to obtain diced meat, and then the diced meat is poured into the nitrogen mixer and added with auxiliary materials and seasonings; then the low-temperature minced meat is extruded by a molding machine, and then passed through battering, flour coating or Crumb wrapping, pre-fried, quick-freezing, packaging, metal detection, boxing, and warehousing are the steps to obtain the crispy bone meat crispy quick-frozen food. The method can efficiently utilize raw materials, improve the utilization rate of raw materials, and reduce production costs; at the same time, the method adopts a mechanical operation mode, which improves production efficiency and reduces human resource costs; Crisp taste and better color have better eating effect.

Owner:辽宁禾丰食品有限公司

Color matching device for full-automatic proofing of yarns

PendingCN113893736AMix evenly and efficientlyImprove color matching effectTransportation and packagingRotary stirring mixersYarnEngineering

The invention discloses a color matching device for full-automatic proofing of yarns. The color matching device comprises a color matching barrel. A feeding groove is connected to the middle of the upper end of the color matching barrel in a penetrating mode, and the feeding groove is communicated with the interior of the color matching barrel. A protective shell is fixedly installed at the lower end of the color matching barrel, and a base is fixedly welded to the lower end of the protective shell. A discharging pipe is connected to the middle of the right end of the color matching barrel in a penetrating mode. An upper mixing area, a driving area and a lower mixing area are sequentially arranged in the color matching barrel from top to bottom, and the driving area is not the same as the interior of the upper mixing area and the interior of the lower mixing area. Conveying grooves are formed in only two sides of the interior of the color matching barrel, and the upper mixing area is communicated with the interior of the lower mixing area through the conveying grooves. A first mixing mechanism is arranged in the upper mixing area. A second mixing mechanism is arranged in the lower mixing area. A transmission assembly is movably installed in the driving area. The color matching device for full-automatic proofing of yarns is compact in structure, stable in transmission, low in cost, uniform and efficient in mixing, good in color matching effect and capable of being used and popularized.

Owner:张家港市华益纺织有限公司

Mixer and processes incorporating the same

InactiveUS10065157B2Speed up the flowWell mixedFlow mixersTransportation and packagingProcess engineering

Owner:BLUE CUBE IP

Ink adjusting device for printing

PendingCN114789012AGuaranteed Concentration UniformityStir evenly and efficientlyTransportation and packagingRotary stirring mixersElectric machineryPrinting ink

The invention discloses an ink mixing device for printing. The ink mixing device comprises a workbench, a stirring barrel, a movable support, an ink mixing device body, a lead screw mechanism, a transition plate and a positioning component. The lead screw mechanism is fixed to the front side face of the movable support. After the stirring barrel is locked and positioned through the positioning part, the lead screw mechanism is controlled to do reciprocating rotary motion so as to drive the ink adjusting device to stir at different depth positions in the stirring barrel; the ink adjusting device comprises a motor, a stirring shaft and a stirring paddle; the motor is used for controlling automatic rotation of the stirring shaft to stir ink, has forward and reverse rotation functions and is provided with different rotating speed regulators, so that the optimal stirring effect is achieved; and the stirring paddle is used for stirring and mixing offset printing ink with different ink colors to form spot color printing ink. The ink adjusting device achieves stirring at different depth positions, radial convection mixing and axial backflow mixing of different laminar flows in the ink adjusting device are ensured, stirring is more efficient and uniform, and then the stirring efficiency is improved.

Owner:赣州市龙源彩印包装有限公司

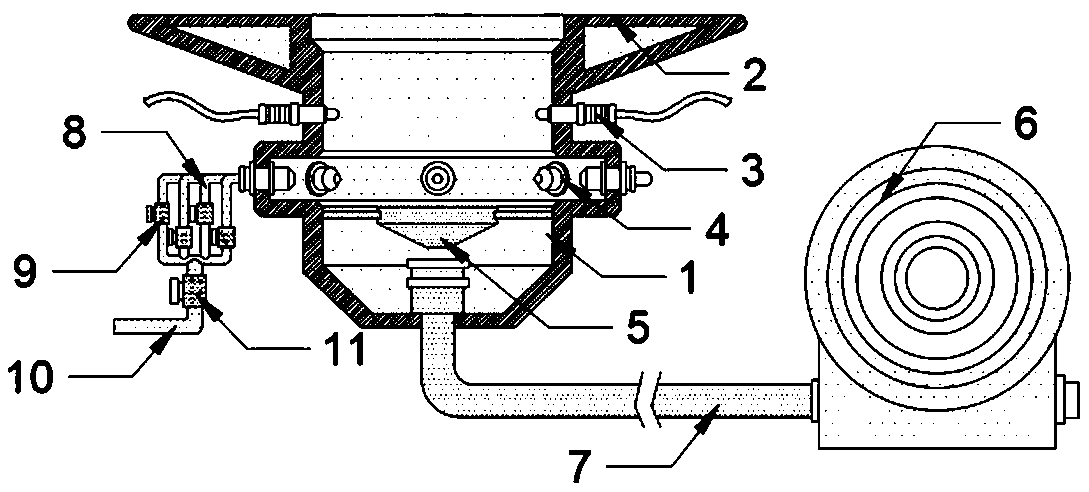

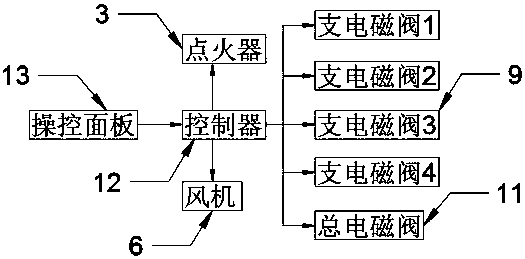

Intelligent premixing control system for gas cooker

InactiveCN110594797AIncrease burn rateMix evenly and efficientlyDomestic stoves or rangesGaseous fuel burnerSolenoid valveControl system

The invention discloses an intelligent premixing control system for a gas cooker. The intelligent premixing control system includes a spray burning barrel, a sealing plate, an igniter, gas nozzles, awind stopping block, a fan, a ventilation pipe, a gas branch pipe, a branch solenoid valve, a gas main pipe, a main solenoid valve, a controller and a control panel; the sealing plate is integrally fixed on the periphery of the top of the spray burning barrel, the eight gas nozzles are evenly embedded and installed in the middle of the spray burning barrel, the gas nozzles at the symmetrical positions of the outer wall of the spray burning barrel are in communication through one gas branch pipe, the gas branch pipe is connected with the gas main pipe, the main solenoid valve is installed in the middle of the gas main pipe, and the branch solenoid valve is installed in the middle of the gas branch pipe. By means of the intelligent premixing control system for the gas cooker, the wind stopping block is adopted for stopping and dispersing ventilation, uniform and flat injection gas is used in cooperation, efficient and uniform mixing of gas and air is completed, the combustion rate of thegas is improved, resource waste is reduced, and meanwhile a system connected to the controller stabilizes entire ignition, and the using safety is high.

Owner:广东炬鼎节能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com