Efficient mixing and detecting integrated device for self-compacting concrete workability

A self-compacting concrete and workability technology, applied in the direction of measuring devices, clay preparation devices, sampling devices, etc., can solve problems such as inaccurate data, poor material performance, and unmaintainable concrete uniformity, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

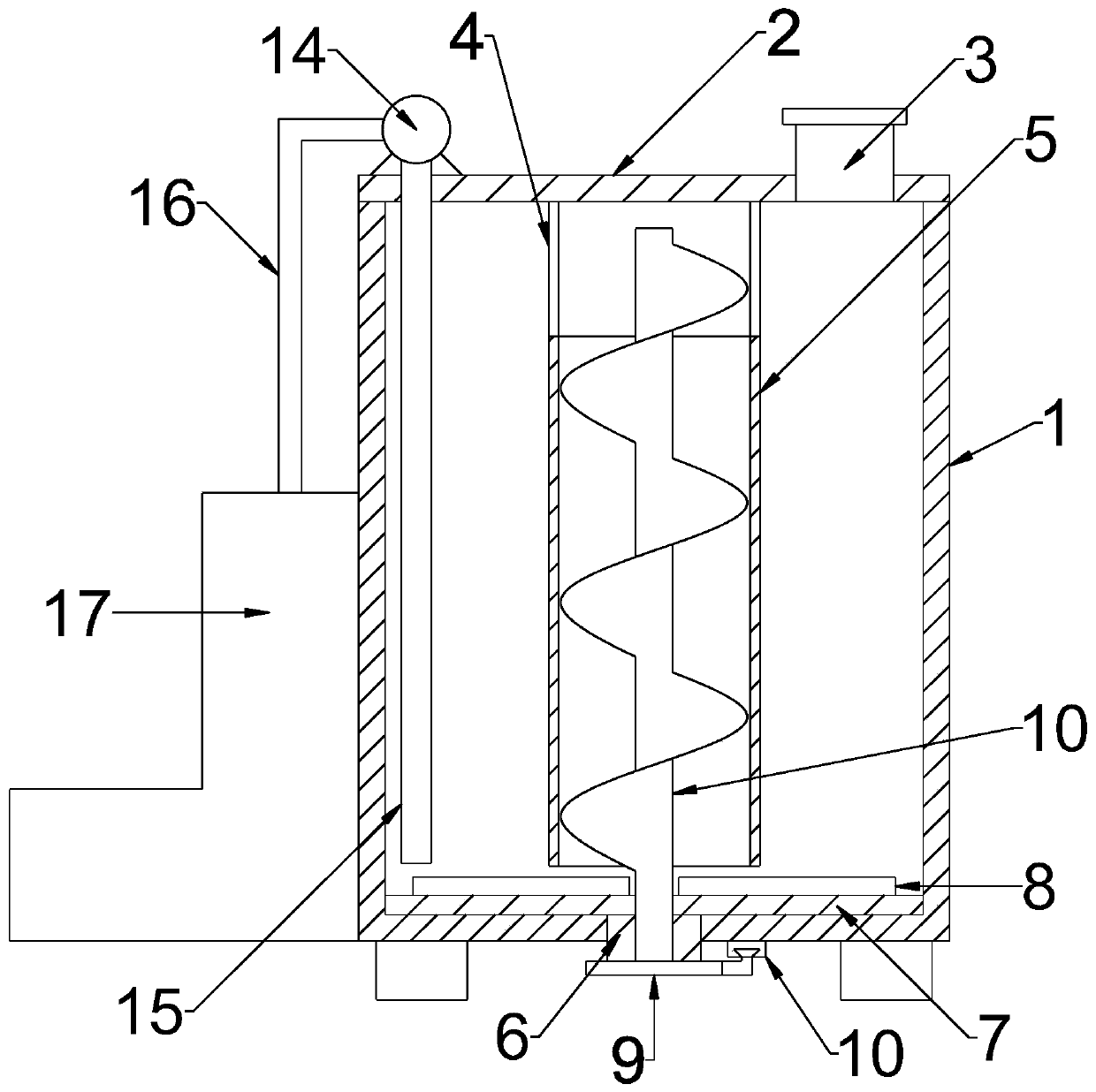

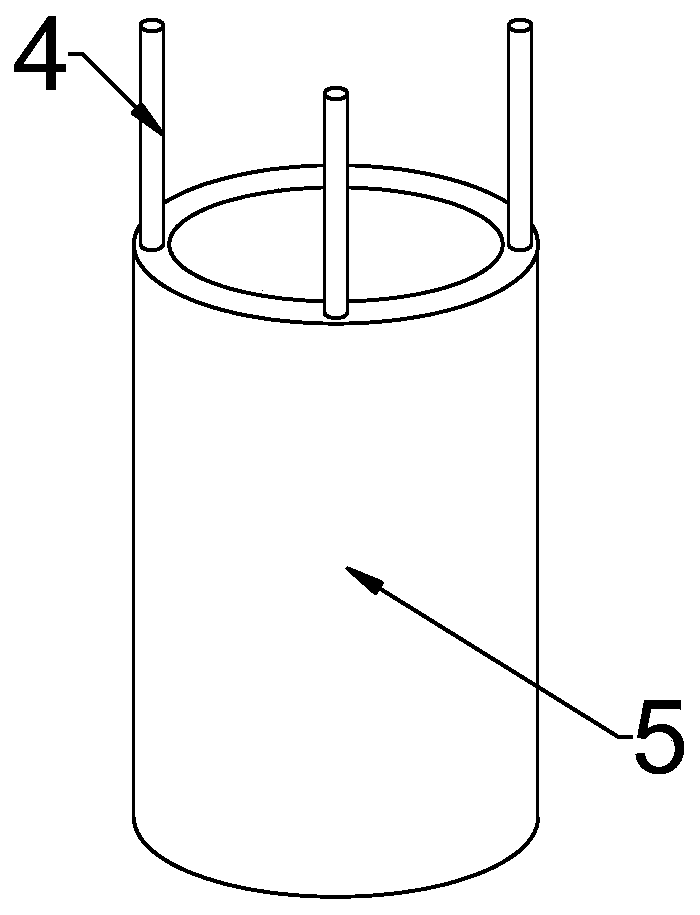

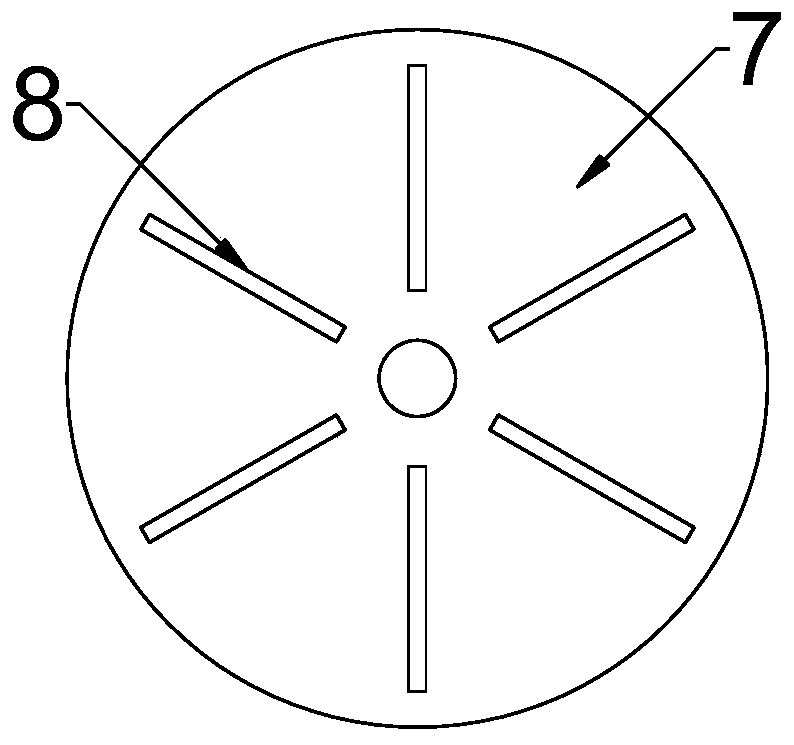

[0020] see Figure 1~3 , in an embodiment of the present invention, a self-compacting concrete workability high-efficiency mixing detection integrated device, including a processing chamber 1 and an L-shaped instrument 17, the upper end of the processing chamber 1 is movably connected with an upper cover 2 through riveting, The upper cover 2 is provided with a feeding mechanism for conveying concrete from the processing chamber 1 to the L-shaped instrument 17. The middle part of the lower end of the processing chamber 1 is rotatably connected with a rotating sleeve 6, and the rotating sleeve 6 is connected with a rotating sleeve 6. The bottom plate 7 and the spiral fan blade 10 , the rotating sleeve 6 is driven by the rotating mechanism 9 to drive the rotating bottom plate 7 to rotate forward and backward, and the rotating sleeve 6 drives the spiral fan blade 10 to perform one-way intermittent rotation.

[0021] The lower end of the upper cover 2 is connected with a lifting ca...

Embodiment 2

[0025] see Figure 4 , in the embodiment of the present invention, on the basis of embodiment 1, a high-efficiency mixing detection integrated device for self-compacting concrete workability, the rotating mechanism 9 includes a transmission gear 91 welded and fixed on the lower end of the rotating sleeve 6 and The ratchet wheel 92 is welded and fixed on the periphery of the lower end of the spiral fan blade 10. The transmission gear 91 has a ring structure. The transmission gear 91 is connected to the drive mechanism for telescopic movement. Transmission strap 93, the transmission strap 93 is a sheet structure, and the end is movable and embedded between the adjacent gear teeth on the periphery of the ratchet 92; when the transmission gear 91 rotates forward and reverse, as shown in the figure, it rotates forward When the transmission strap 93 moves and fits the tooth surface of the ratchet 92, the ratchet 92 remains in a non-rotating state. When the transmission gear 91 rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com