A kind of production method of quick-frozen food with crispy bone and meat prepared by using poultry bone meat

A production method and technology of crispy meat, which is applied in the field of quick-frozen crispy meat crispy food and its production, can solve the problems of low operating efficiency, high production cost, high human resource cost, etc., and achieve the effect of reducing cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

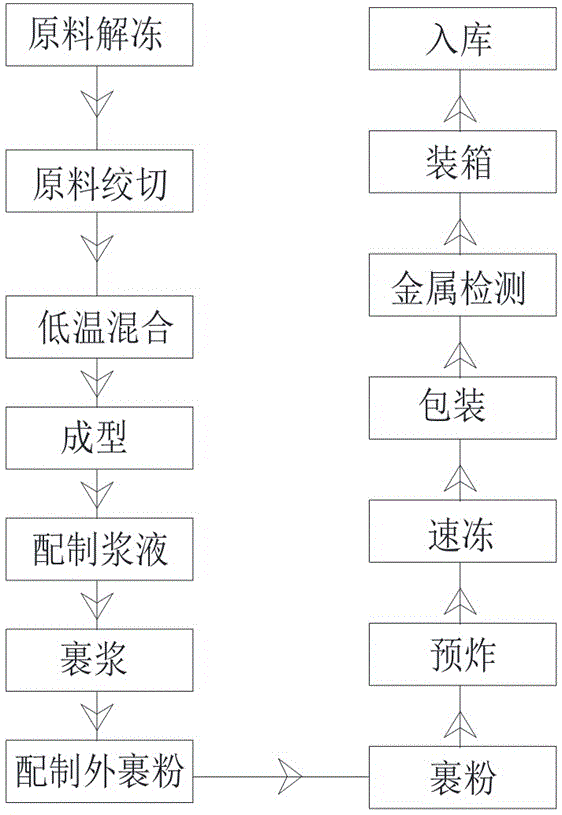

[0047] The technical solution adopted by the present invention is a quick-frozen crispy meat crispy food prepared by using poultry flesh and bone. The crispy bone meat crispy quick-frozen food uses broken breast cartilage, leg meat and breast meat of poultry as raw materials, and the raw materials are crushed in a meat grinder with a diameter of 10mm Cut the diced meat with a stencil, then pour the diced meat into the nitrogen mixer and add auxiliary materials and seasonings, inject nitrogen cold medium into the nitrogen mixer, stir at low temperature and low speed, the temperature of the minced meat is -3°C Then utilize the forming machine to extrude the low-temperature minced meat, and then obtain the crispy meat crispy quick-frozen food through battering, flour coating, pre-fried, quick-freezing, packaging, metal detection, packing, and warehousing; The components of the quick-frozen food are by weight: 20 parts of cartilage, 60 parts of leg meat and breast meat, 20 parts of...

Embodiment 2

[0049] A kind of quick-frozen crispy meat crispy food prepared from poultry bone and meat. The crispy bone meat quick-frozen food uses poultry minced breast cartilage and leg meat as raw materials, and the raw materials are minced with a mesh plate with a diameter of 10mm in a meat grinder to obtain diced meat. Then pour the diced meat into the nitrogen mixer and add auxiliary materials and seasonings, inject carbon dioxide cold medium into the nitrogen mixer, stir at low temperature and low speed, the temperature of the minced meat is -5°C; Extrusion molding, and then through battering, crumb wrapping, pre-fried, quick-freezing, packaging, metal detection, packing, and warehousing to obtain the crispy and crispy quick-frozen food; the components of the crispy quick-frozen food are by weight: : 30 parts of cartilage, 40 parts of leg meat, 30 parts of auxiliary materials, 15 parts of slurry, 20 parts of wrapping material.

Embodiment 3

[0051] A kind of quick-frozen crispy meat crispy food prepared from poultry bone and meat. The crispy bone meat crispy quick-frozen food uses poultry minced breast cartilage and breast meat as raw materials, and the raw materials are minced with a mesh plate with a diameter of 10mm in a meat grinder to obtain diced meat. Then pour the diced meat into the nitrogen mixer and add auxiliary materials and seasonings, inject nitrogen cold medium into the nitrogen mixer, stir at low temperature and low speed, the temperature of the minced meat is -4°C; then use the molding machine to make the low temperature minced meat Extrusion molding, and then through battering, breading, pre-fried, quick-freezing, packaging, metal detection, packing, and warehousing to obtain the crispy meat crispy quick-frozen food; the components of the crispy bone meat crispy quick-frozen food are by weight : 30 parts of cartilage, 40 parts of leg meat and breast meat, 20 parts of auxiliary materials, 10 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com