Multi-component weft triple fabric and weaving process thereof

A multi-component and fabric technology, applied in the direction of multi-strand fabrics, fabrics, manufacturing tools, etc., can solve the problems of poor moisture absorption and air permeability, poor wearing comfort, high cost, etc., and achieve good anti-wrinkle and shape retention, excellent antibacterial and antibacterial Sex, keep dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

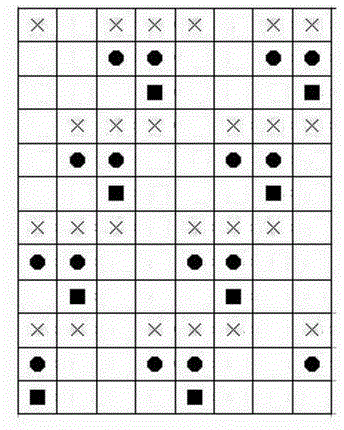

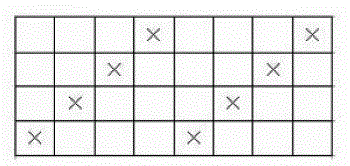

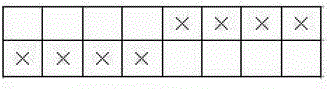

[0027] Such as figure 1 As shown, a multi-component weft triple fabric is characterized in that: the fabric is composed of five components such as cotton, Coolmax modified polyester fiber, hemp, conductive thread, and polyester filament; four kinds of yarns are used, and the warp yarn is 14.5 Tex combed cotton / Coolmax modified polyester fiber (75 / 25); there are four kinds of weft yarns, which are 14.5 Tex combed cotton / Coolmax modified polyester fiber (75 / 25), 75 denier Polyester low-elastic network yarn, 14.5 Tex combed cotton / hemp (70 / 30) and polyester 75 denier 18 denier conductive yarn; the fabric structure adopts weft triple weave, and the front is 14.5 Tex Combed cotton / Coolmax modified polyester fiber (75 / 25) warp and weft, the middle layer is 75 denier polyester low-elastic network yarn, and the reverse side is 14.5 Tex combed cotton / hemp (70 / 25 30) Blended yarn; the warp density of the fabric is 630 threads / 10cm, the weft density is 380 threads / 10cm, the width is 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com