Solvent equal-ratio blending device for disinfectant production

A disinfectant and solvent technology, applied in the field of blending devices, can solve the problems of low blending efficiency, achieve the effect of improving blending efficiency, improving the overall stroke, and increasing the frequency of reciprocating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

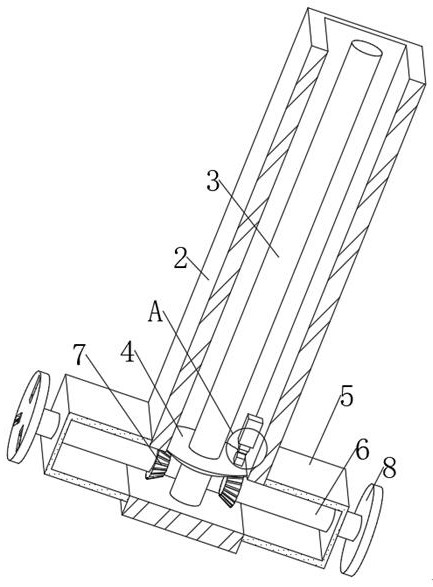

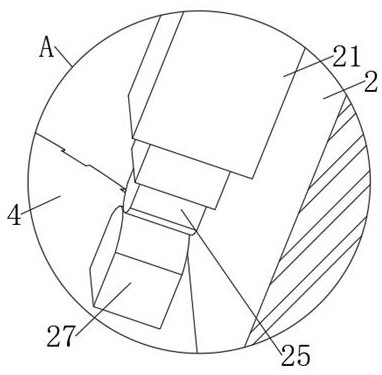

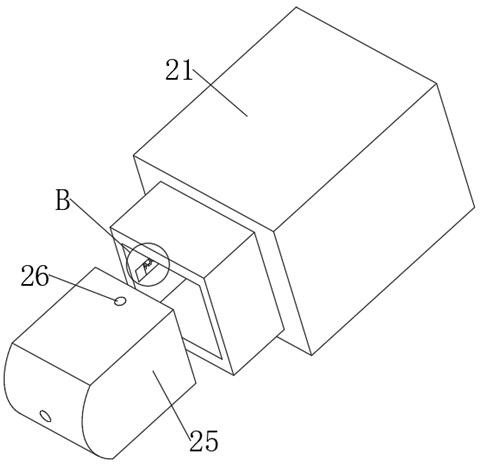

[0034] refer to Figure 1-7, a solvent equal ratio blending device for disinfectant production, comprising a box body 1, a box cover 11 is arranged on the top of the box body 1, a standpipe 2 is fixed through the top of the box cover 11, and the bottom inner wall of the standpipe 2 is connected with a main shaft through bearing rotation 3. An incomplete bevel gear 4 is sleeved and fixed on the main shaft 3. The bottom of both sides of the vertical tube 2 is connected with the horizontal tube 5. The side wall of the horizontal tube 5 runs through and is connected to the sub-axis 6 through the bearing rotation. The inner side of the sub-axis 6 is passed through the bolt The complete bevel gear 7 is fixed, and the complete bevel gear 7 is meshed with the incomplete bevel gear 4. The motor 9 is fixed on the top of the standpipe 2 by bolts. The output shaft of the motor 9 and the main shaft 3 are fixed by bolts. A disc 8 is fixed, and a plurality of first chutes 12 arranged in an a...

Embodiment 2

[0041] refer to figure 1 and Figure 8-10 , a solvent equal ratio blending device for disinfectant production, a liquid storage tube 28 is fixed through the top of the box cover 11, the section of the liquid storage tube 28 is set in an inverted convex shape, a bottom plate 29 is placed inside the liquid storage tube 28, and the bottom of the bottom plate 29 passes through The push rod 30 is fixed by bolts, and the bottom of the push rod 30 is fixed with an arc-shaped block. The inner walls on both sides of the box body 1 are connected to the connecting shaft 36 through bearing rotation, and the outer wall of the connecting shaft 36 is fixed by bolts. The transmission rod 37 and the connecting shaft 36 are arranged between the fixed rod 15 and the case cover 11 .

[0042] Further, the inner wall of the front end of the liquid storage pipe 28 is fixedly connected with an electronic scale, and the electronic scale is arranged below the bottom plate 29. The front end of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com