A kind of preparation technology of liquor

A preparation process and liquor technology, applied in the field of liquor preparation technology, can solve the problems of large differences in taste of finished liquor, single mechanical stirring of liquor, difficulty in achieving uniform mixing of liquor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A preparation process of liquor, including:

[0021] (1) Material pretreatment, select the rice produced in the current year as the raw rice, wash the raw rice, soak it in warm water at 45°C for 35 minutes, and then drain it to dry;

[0022] (2) For steaming, spread sorghum mince on the steamer, and lay the freshly picked sorghum leaves on the sorghum mince. Use a bayonet to pierce several vents on the sorghum leaves and sorghum mince to spread the raw rice. Steam the sorghum leaves. After the steaming is completed, the raw rice is immersed in cold water to cool down. At the same time, the raw rice is continuously moved to loosen the raw rice. After the raw rice is cooled, the raw rice is dried with cold air and dried During the process, keep moving the raw rice to prevent the raw rice from clumping;

[0023] (3) Mix the koji, activate the koji with warm water, and stir it into the raw rice;

[0024] (4) Fermentation and distillation: Put the raw rice mixed with ...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 lies in: in the material pretreatment step, the raw rice is soaked in 40°C warm water for 40 minutes; in the fermentation distillation step, 2.3Kg of wine heads are cut off; when blending, the blower 14 and ventilation The tube 18 is cycled on and off 4 times.

Embodiment 3

[0031] The difference between this example and Example 1 and Example 2 lies in: in the material pretreatment step, the raw rice is soaked in warm water at 35°C for 45 minutes; in the fermentation distillation step, 2.5Kg of wine heads are cut off; The tube 14 and the ventilation tube 18 are opened and closed 5 times in a cycle.

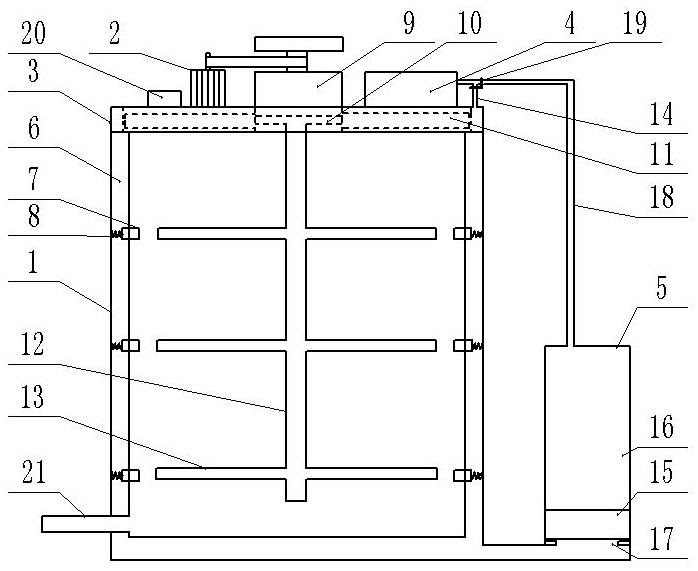

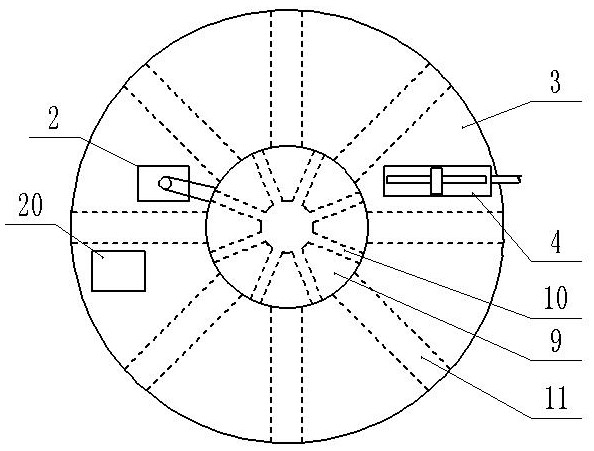

[0032] In actual application, when the motor 2 is working, the motor 2 drives the turntable 9 to rotate, and the stirring shaft 12 rotates along with it to mechanically stir the liquor through the stirring tube 13. At the same time, the blowing pipe 14 is turned on and the ventilation pipe 18 is closed. The fan 4 blows from the blowing pipe 14 to the second passage 11. When the first passage 10 rotates with the turntable 9 and is aligned with the second passage 11, the air flow is blown by the second passage 11. It enters the first channel 10 and flows into the mixing shaft 12 from the first channel 10, and is finally blown out into the blending tank 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com