Gasoline online blending method

A blending method and gasoline technology, applied in control/regulation systems, instruments, adaptive control, etc., can solve problems such as increased loss, inaccurate control of product quality, and high edge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

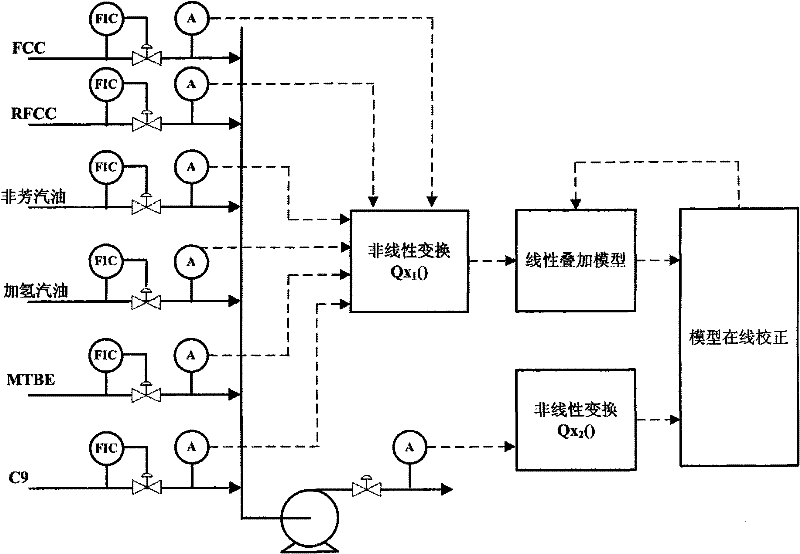

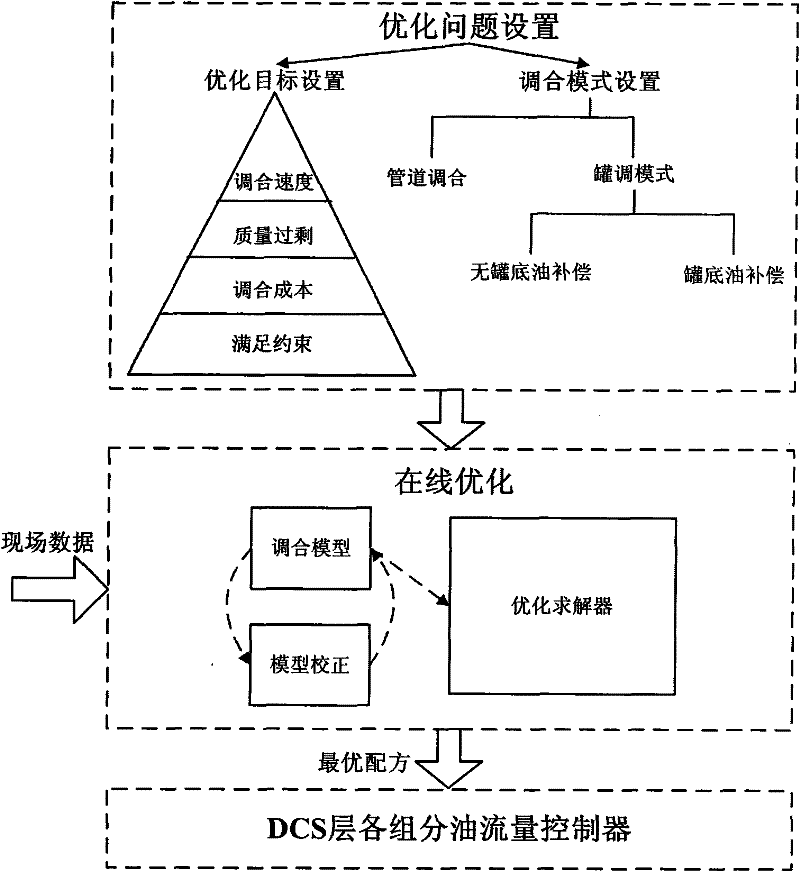

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below with reference to the accompanying drawings and embodiments.

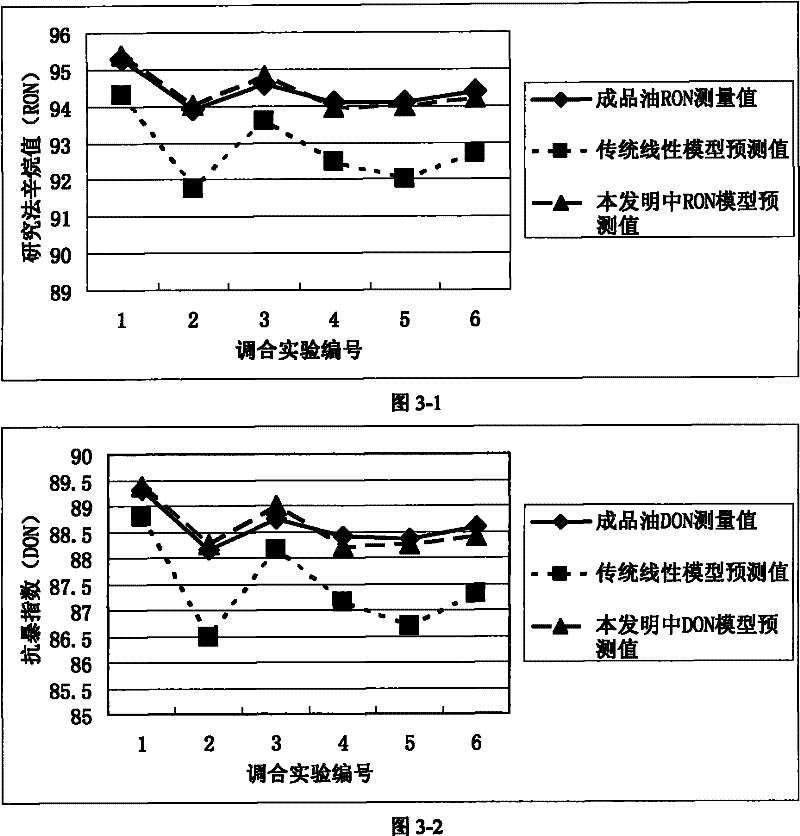

[0078] First, in order to establish a gasoline blending model, especially the model of RON and DON attributes, a blending experiment was conducted to select the appropriate blending formula for each grade of gasoline. Corresponding blending experiments adopt manual methods and laboratory analysis methods to collect oil property data P of each component j,i and the corresponding blended product oil property data P j l . Based on the collected data, the pb in the blending model formula (1) is obtained by linear regression j,i value. The linear regression method is as follows:

[0079] r 1,1 r 1,2 . . . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com