Mechanized tea leaf production process capable of reducing tea leaf damage

A production process and tea technology, applied in the field of mechanized tea production process, can solve the problems of low efficiency, unstable mixing effect, damage to the integrity of tea leaves, etc., and achieve the effects of uniform mixing, saving manpower and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The mechanized tea production process for reducing tea damage disclosed in this embodiment comprises the following steps,

[0031] S1, collect green tea from different production areas respectively, and make raw tea from the green tea from each production area;

[0032] S2, preliminarily mixing raw tea from each production area in proportion to prepare mixed raw tea;

[0033] S3. Input the mixed raw tea into a mixing barrel for mechanized blending, and the mixing barrel automatically outputs the raw tea while mixing and blending, so as to obtain blended raw tea of the same grade;

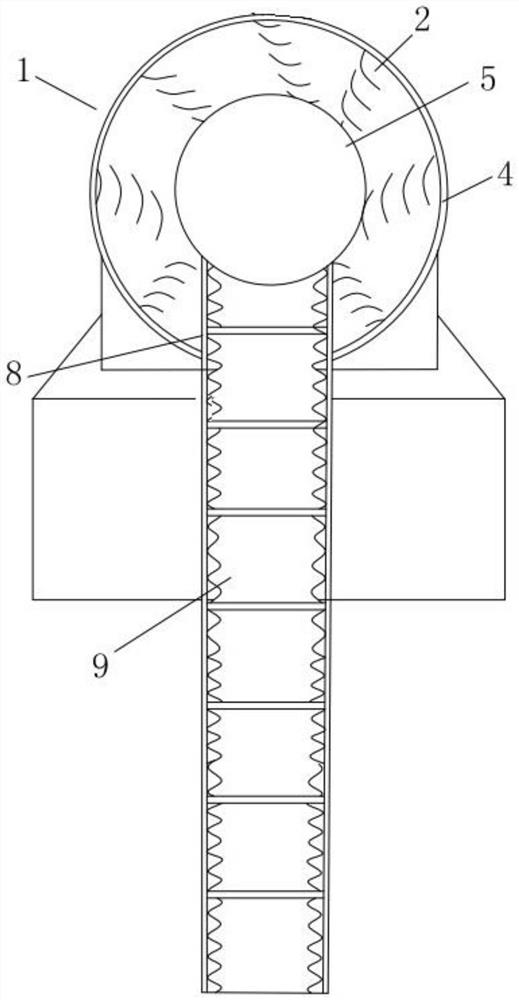

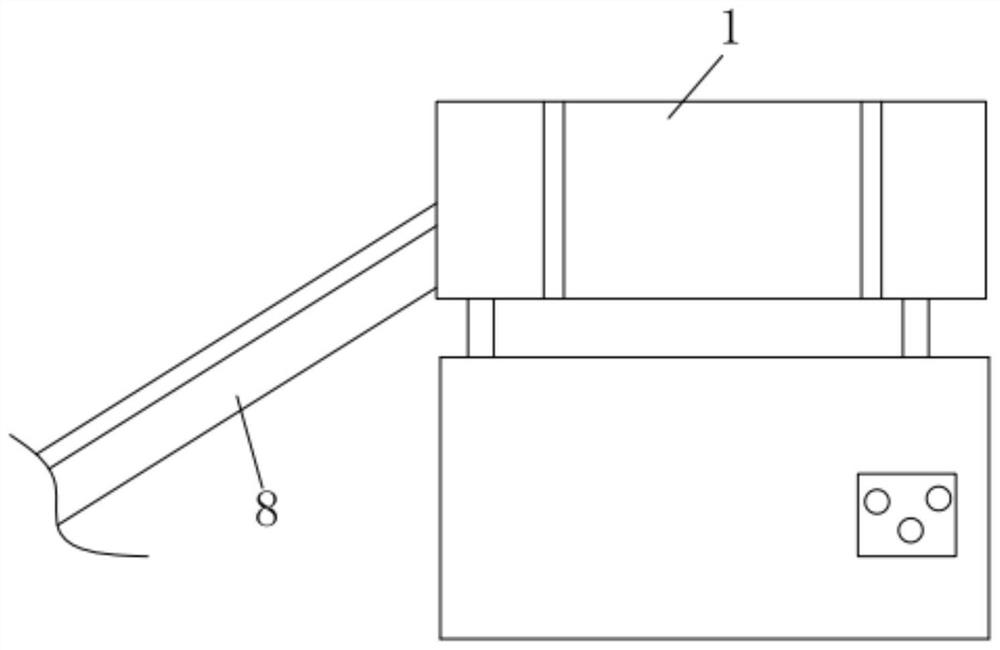

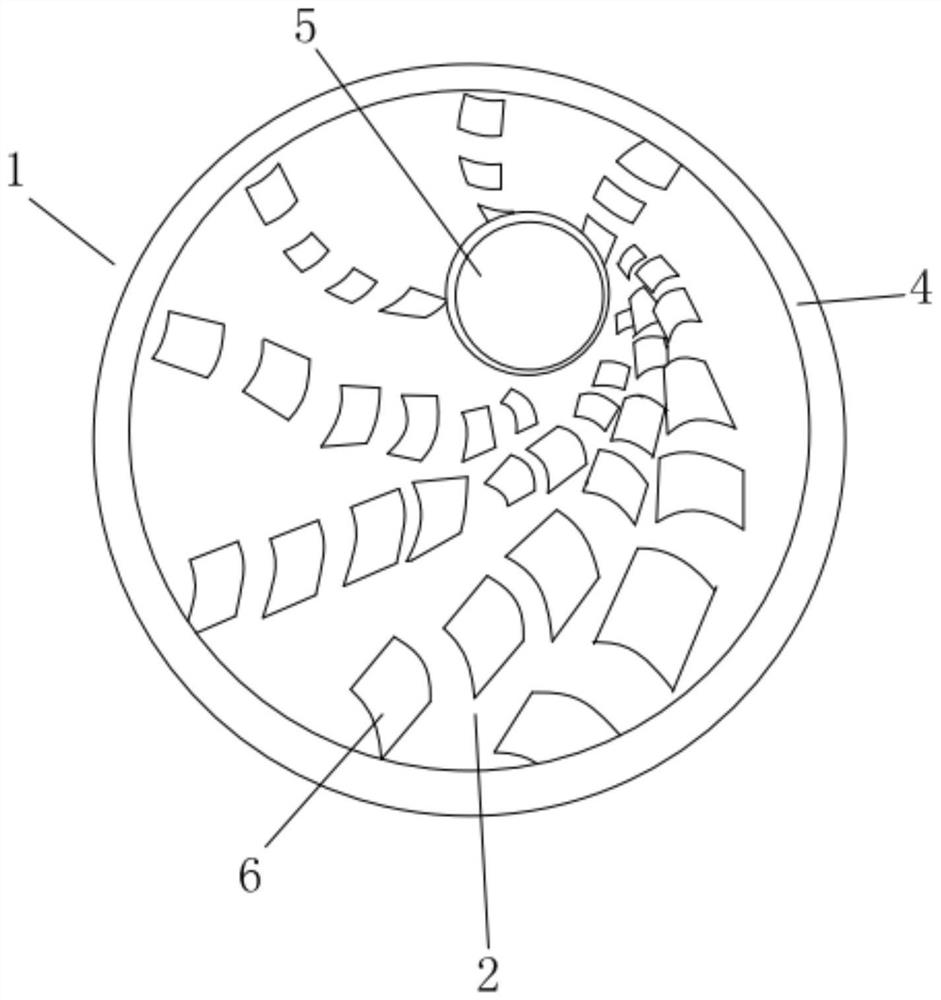

[0034] in, Figure 1-Figure 2 As shown, the mixing cylinder is placed horizontally, and the mixing cylinder 1 can rotate around its central axis. Figure 3-Figure 4 As shown, at least two blade tracks 2 are arranged in the mixing tube 1, and each blade track 2 extends spirally along the inner wall of the mixing tube 1, and each blade track 2 extends from the mixing tube 1 The feed inlet ...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that the mixing cylinder 1 mixes and blends the primary mixed raw tea for 1 minute, and other components and principles are the same as those of embodiment 1, and will not be repeated here.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is that the mixing cylinder 1 mixes and blends the primary mixed raw tea for 3 minutes, and the other components and principles are the same as those of embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com