Powder modification tank

A technology of powder modification and tank body, which is applied in the direction of cleaning hollow articles, mixers, feeding devices, etc., can solve the problems of low modification efficiency and quality, local unevenness, etc., and achieves improved efficiency and modified quality, Large mixing range and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

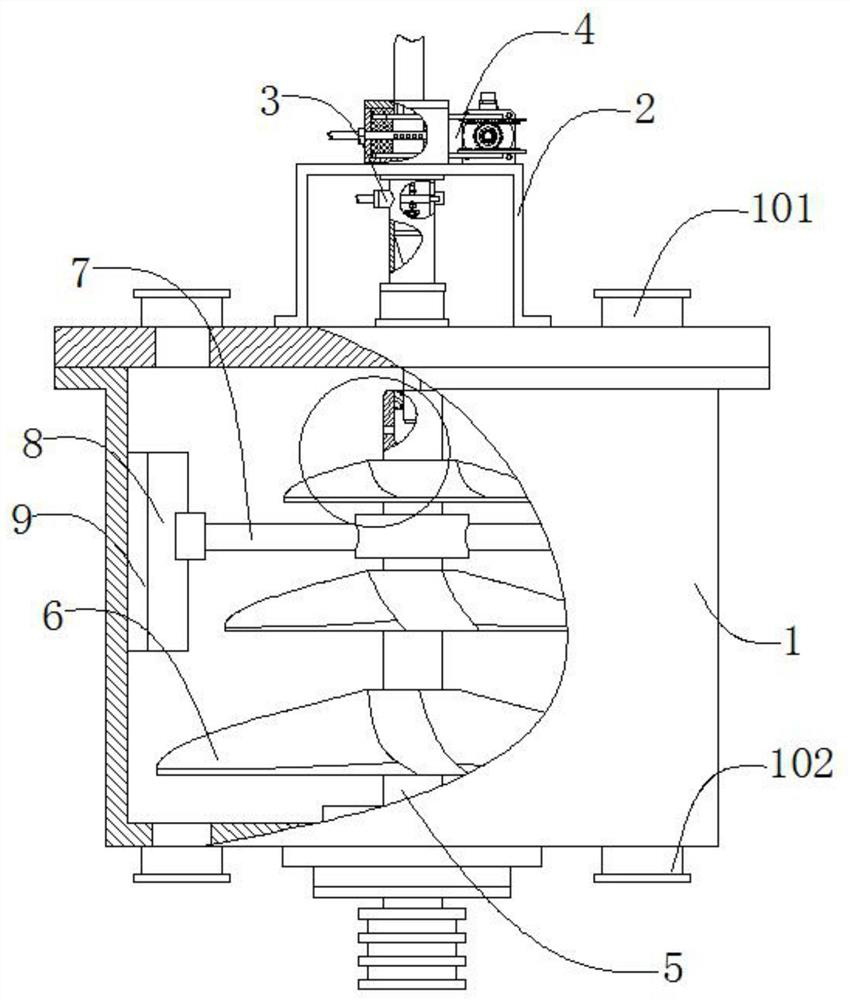

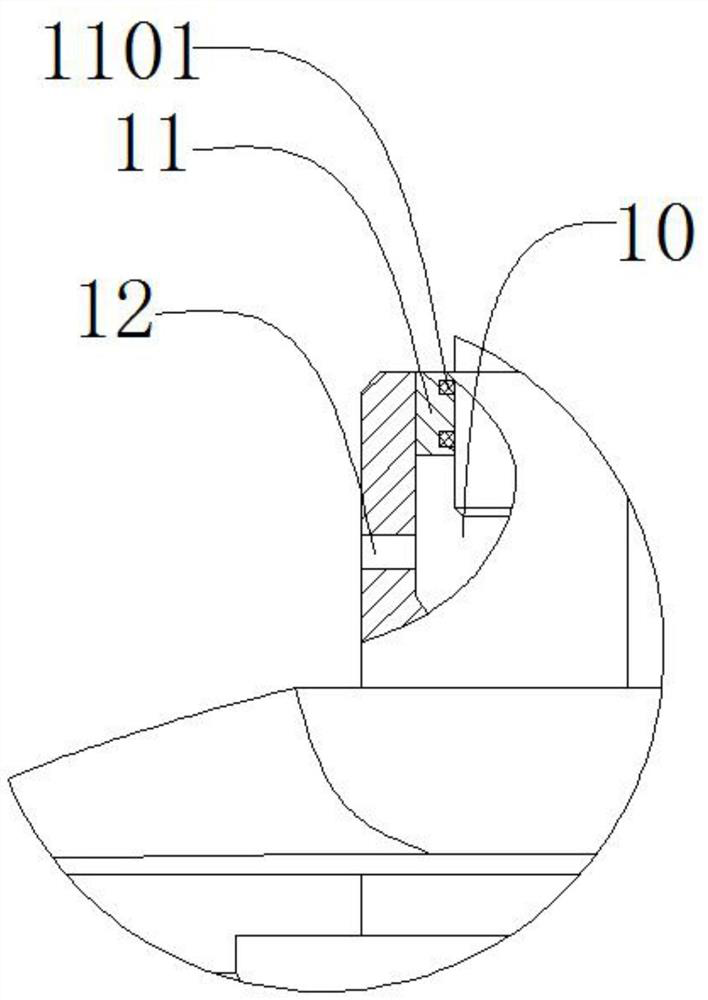

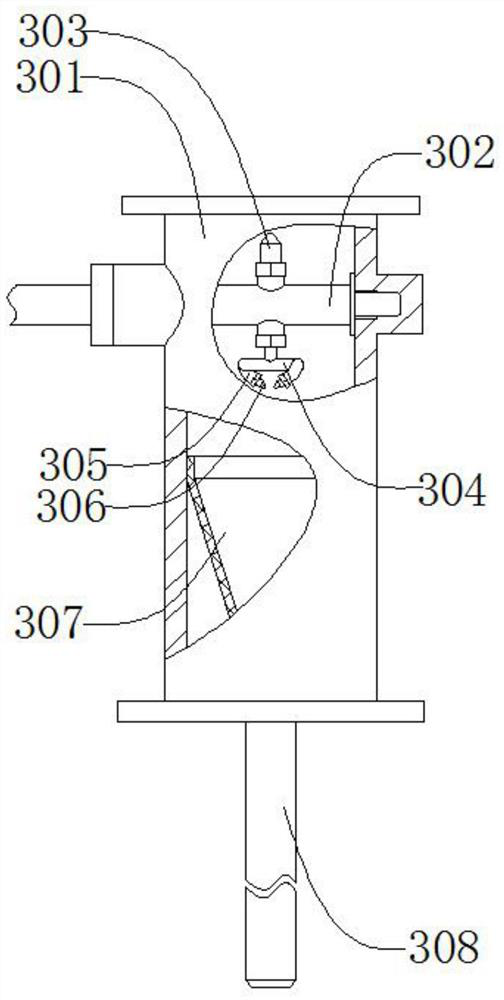

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a powder modification tank includes a tank body 1, a bracket 2, a powder spraying mechanism 3, a premixing mechanism 4, a rotating shaft 5, an impeller 6, a support rod 7, a pushing plate 8, a scraper 9, a material storage Groove 10, sealing seat 11, powder injection hole 12, described bracket 2 is located at the center of the upper end of tank body 1, and described bracket 2 is connected with tank body 1 by bolts, and described powder injection mechanism 3 is located at the lower end of bracket 2 and Extending into the tank body 1, the powder spraying mechanism 3 is connected with the bracket 2 and the tank body 1 through bolts, the premixing mechanism 4 is located at the upper end of the bracket 2, and the premixing mechanism 4 is connected with the bracket 2 through bolts , one end of the rotating shaft 5 extends into the tank body 1, the rotating shaft 5 is connected with the tank body 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com